Abstract

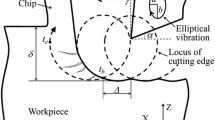

The completion of machining in one setting leads to high accuracy and quality. Since ordinary machining is not capable of fabricating sharp corners, electrical discharge machining (EDM) is used. However, this requires a highly skilled machinist to set up the workpiece to maintain the accuracy of the product since two or more set-ups are involved in this process. In this study, a new manufacturing method for the fabrication of sharp corners is examined experimentally. Six-axis controlled cutting using a bore byte tool with the application of ultrasonic vibration has been applied in this method. Experimental resultshave shown the applicability of this method in the fabrication of sharp corners.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Japitana, F., Morishige, K. & Takeuchi, Y. Six-Axis Controlled Ultrasonic Vibration Cutting in Fabrication of a Sharp Corner . Int. Journ. Adv. Manufac. Tech. 21, 564–570 (2003). https://doi.org/10.1007/s00170-002-1344-9

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1344-9