Abstract

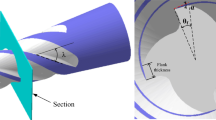

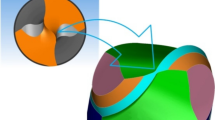

A new grinding method using a torus-shaped grinding wheel and a machining path generation method with a novel moving coordinate system are proposed. With this new grinding method, the smooth spiral rake surface of a taper ball-end mill with constant helical angle and constant normal rake angle can be formed during one grinding process and the normal rake angle can be obtained accurately. The novel moving coordinate system is established based on taking account of both the cutting edge curve and the cutter body surface. By means of the novel moving coordinate system, the machining path generation becomes very simple. The proposed grinding method and the machining path generation method are verified by 3D simulation results.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, D., Hongzon, B. CNC Rake Grinding for a Taper Ball-End Mill with a Torus-Shaped Grinding Wheel . Int. Journ. Adv. Manufac. Tech. 21, 549–555 (2003). https://doi.org/10.1007/s00170-002-1298-y

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1298-y