Abstract

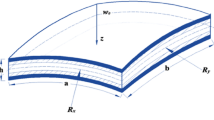

This paper presents a semi-analytic rigid/plastic solution for the expansion/contraction of a hollow sphere at large strains. The yield stress depends on the equivalent strain rate and the equivalent strain. No restriction is imposed on this dependence. The solution reduces to a single ordinary differential equation for determining the radial stress. The independent variable in this equation is the equivalent strain. Moreover, the equivalent strain rate is expressed in terms of elementary functions of the equivalent strain, which allows for representing the yield stress as a function of the equivalent strain and a time-like independent variable. In the course of deriving the equations above, the transformation between Eulerian and Lagrangian coordinates is used. A numerical example illustrates the solution for a material model available in the literature. The motivation of this research is that solutions for the expansion/contraction of a hollow sphere are widely used at the micro-level to calculate some material properties at the macro-level. To this end, it is necessary to specify constitutive equations for micromechanical modeling. The accuracy of these equations is questionable. An advantage of the solution found is that it is practically analytic for quite a general material model that accounts for both strain- and rate-hardening. Therefore, it is straightforward to generate a large amount of theoretical data for comparing with measurable quantities at the macro-level.

Similar content being viewed by others

References

Hill, R.: The Mathematical Theory of Plasticity. Oxford University Press, Oxford (1950)

Durban, D., Baruch, M.: Analysis of an elasto-plastic thick walled sphere loaded by internal and external pressure. Int. J. Non-Linear Mech. 12, 9–21 (1977)

Carroll, M.M., Kim, K.T.: Pressure-density equations for porous metals and metal powders. Powder Metall. 27, 153–159 (1984)

Wilkinson, D.S., Ashby, M.F.: Pressure sintering by power law creep. Acta Metall. 23, 1277–1285 (1975)

Haghi, M., Anand, L.: Analysis of strain-hardening viscoplastic thick-walled sphere and cylinder under external pressure. Int. J. Plast. 7, 123–140 (1991)

Thore, P., Pastor, F., Pastor, J., Kondo, D.: Closed-form solutions for the hollow sphere model with Coulomb and Drucker–Prager materials under isotropic loadings. C. R. Mec. 337, 260–267 (2009)

Johnson, G.R., Cook, W.Y.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21(1), 31–48 (1985)

Meyer, H.W., Jr., Kleponis, D.S.: Modeling the high strain rate behavior of titanium undergoing ballistic impact and penetration. Int. J. Impact Eng. 26, 509–521 (2001)

Siegel, A., Laporte, S., Sauter-Starace, F.: Johnson–Cook parameter identification for commercially pure titanium at room temperature under quasi-static strain rates. Materials 14, Article 3887 (2021)

Ashrafian, M.M., Kordkheili, S.A.H.: A novel phenomenological constitutive model for Ti–6Al–4V at high temperature conditions and quasi-static strain rates. Proc. IMechE Part G J. Aerosp. Eng. 235(13), 1831–1842 (2021)

Alister, F., Celentano, D., Signorelli, J., Bouchard, P.-O., Munoz, D.P., Cruchaga, M.: Viscoplastic and temperature behavior of Zn–Cu–Ti alloy sheets: experiments, characterization, and modeling. J. Mater. Res. Technol. 15, 3759–3772 (2021)

Rusinek, A., Zaera, R., Klepaczko, J.R.: Constitutive relations in 3-D for a wide range of strain rates and temperatures—application to mild steels. Int. J. Solids Struct. 44, 5611–5634 (2007)

Jia, B., Rusinek, A., Pesci, R., Bahi, S., Bernier, R.: Thermo-viscoplastic behavior of 304 austenitic stainless steel at various strain rates and temperatures: testing, modeling and validation. Int. J. Mech. Sci. 170, 105356 (2020)

Cheng, W., Outeiro, J., Costes, J.-P., M’Saoubi, R., Karaouni, H., Denguir, L., Astakhov, V., Auzenat, F.: Constitutive model incorporating the strain-rate and state of stress effects for machining simulation of titanium alloy Ti6Al4V. Proc. CIRP 77, 344–347 (2018)

Cheng, W., Outeiro, J., Costes, J.-P., M’Saoubi, R., Karaouni, H., Astakhov, V.: A constitutive model for Ti6Al4V considering the state of stress and strain rate effects. Mech. Mater. 137, 103103 (2019)

Dos Santos, T., Outeiro, J.C., Rossi, R., Rosa, P.: A new methodology for evaluation of mechanical properties of materials at very high rates of loading. Proc. CIRP 58, 481–486 (2017)

Kim, H., Yoon, J.W., Chung, K., Lee, M.-G.: A multiplicative plastic hardening model in consideration of strain softening and strain rate: theoretical derivation and characterization of model parameters with simple tension and creep test. Int. J. Mech. Sci. 187, 105913 (2020)

Attar, H.R., Li, N., Foster, A.: A method for determining equivalent hardening responses to approximate sheet metal viscoplasticity. MethodsX 8, 101554 (2021)

Bodner, S.R., Partom, Y.: Constitutive equations for elastic-viscoplastic strain-hardening materials. Trans. ASME J. Appl. Mech. 42, 385–389 (1975)

Leu, S.-Y.: Analytical and numerical investigation of strain-hardening viscoplastic thick-walled cylinders under internal pressure by using sequential limit analysis. Comput. Methods Appl. Mech. Eng. 196, 2713–2722 (2007)

Leu, S.-Y.: Limit analysis of strain-hardening viscoplastic cylinders under internal pressure by using the velocity control: analytical and numerical investigation. Int. J. Mech. Sci. 50, 1578–1585 (2008)

Leu, S.-Y.: Investigation of rotating hollow cylinders of strain-hardening viscoplastic materials by sequential limit analysis. Comput. Methods Appl. Mech. Eng. 197, 4858–4865 (2008)

Alexandrov, S., Hwang, Y.-M.: Plane strain bending with isotropic strain hardening at large strains. Trans. ASME J. Appl. Mech. 77, 064502 (2010)

Alexandrov, S., Pirumov, A., Jeng, Y.-R.: Expansion/contraction of a spherical elastic/plastic shell revisited. Contin. Mech. Thermodyn. 27, 483–494 (2015)

Alexandrov, S., Jeng, Y.-R.: An elastic/plastic solution for a hollow sphere subject to thermo-mechanical loading considering temperature dependent material properties. Int. J. Solids Struct. 200–201, 23–33 (2020)

Collins, I.F., Meguid, S.A.: On the influence of hardening and anisotropy on the plane-strain compression of thin metal strip. ASME J. Appl. Mech. 44, 271–278 (1977)

Adams, M.J., Briscoe, B.J., Corfield, G.M., Lawrence, C.J., Papathanasiou, T.D.: An analysis of the plane-strain compression of viscoplastic materials. ASME J. Appl. Mech. 64, 420–424 (1997)

Alexandrov, S., Jeng, Y.-R.: Compression of viscoplastic material between rotating plates. ASME J. Appl. Mech. 76, 031017 (2009)

Roberts, S.M., Hall, F., Van Bael, A., Hartley, P., Pillinger, I., Sturgess, E.N., Van Houtte, P., Aernoudt, E.: Benchmark tests for 3-D, elasto-plastic, finite-element codes for the modelling of metal forming processes. J. Mater. Process. Technol. 34, 61–68 (1992)

Abali, B.E., Reich, F.A.: Verification of deforming polarized structure computation by using a closed-form solution. Contin. Mech. Thermodyn. 32, 693–708 (2020)

Lee, Y., Dawson, P.R.: Obtaining residual stresses in metal forming after neglecting elasticity on loading. ASME J. Appl. Mech. 56, 318–327 (1989)

Acknowledgements

This work was financially supported by the Ministry of Science and Technology of Taiwan (MOST 106-2923-E-194-002-MY3, 108- 2221-E-006-228-MY3 and 108-2119-M-006-010) and Air Force Office of Science Research (AFOSR) under contract no. FA4869- 06-1-0056 AOARD 064053. Professor Yeau-Ren Jeng would like to acknowledge Medical Device Innovation Center (MDIC) and Intelligent Manufacturing Research Center (iMRC) from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan and AC2T research GmbH (AC2T) in Austria (COMET InTribology, FFG-No.872176).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alexandrov, S., Jeng, YR. Finite strain expansion/contraction of a hollow sphere made of strain- and rate- hardening material. Continuum Mech. Thermodyn. 34, 1113–1124 (2022). https://doi.org/10.1007/s00161-022-01103-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-022-01103-w