Abstract

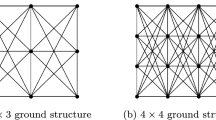

We consider the problem of designing lightweight, load-bearing planar frame structures for additive manufacturing, which can be formulated as a nonlinear, non-convex mathematical programming problems. Even using state-of-the-art commercial solvers, exact methods are only capable of solving small unrealistic instances (with very few variables). In this paper, we develop a heuristic method which is fast and capable of solving the design problem for larger-scale, weight-optimized, planar frame structures for additive manufacturing. The approach explicitly considers manufacturability constraints stemming from the use of additive manufacturing technology and leverages the problem structure imposed by these constraints. The proposed heuristic method is based on iteratively resolving a relaxed master problem on a reduced ground structure. The approach differs from the existing methods in two important aspects. First, we consider planar frame optimization master problem directly (instead of simpler but less relevant truss optimization). Secondly, we employ both element and node addition, which allows us to enforce additive manufacturability constraints without using binary variables (and hence, avoiding the need for computationally expensive integer programming).

Similar content being viewed by others

References

AISC (2005) Steel construction manual. Amer Inst of Steel Construction, Chicago

Becker ST, Bolte H, Krapf O, Seitz H, Douglas T, Sivananthan S, Wiltfang J, Sherry E, Warnke PH (2009) Endocultivation: 3D printed customized porous scaffolds for heterotopic bone induction. Oral Oncol 45(11):e181–e188

Bendsoe MP, Sigmund O (2013) Topology optimization: theory, methods, and applications. Springer, New York

Dorn W (1964) Automatic design of optimal structures. J de Mecanique 3:25–52

Fairclough H, Gilbert M (2020) Layout optimization of simplified trusses using mixed integer linear programming with runtime generation of constraints. Struct Multidisc Optim 61(5):1977–1999

Gally T, Gehb CM, Kolvenbach P, Kuttich A, Pfetsch ME, Ulbrich S (2015) Robust truss topology design with beam elements via mixed integer nonlinear semidefinite programming. Appl Mech Mater Trans Tech Publ 807:229–238

Gao G, Li Y, Pan H, Chen L, Liu Z (2017) An effective members-adding method for truss topology optimization based on principal stress trajectories. Eng Comput 34(6):2088–104

Gao G, Zy L, Yb L, Yf Q (2017) A new method to generate the ground structure in truss topology optimization. Eng Optim 49(2):235–251

Gilbert M, Tyas A (2003) Layout optimization of large-scale pin-jointed frames. Eng Comput 20(8):1044–64

Gurobi Optimization L (2021) Gurobi optimizer reference manual. http://www.gurobi.com

Hagishita T, Ohsaki M (2009) Topology optimization of trusses by growing ground structure method. Struct Multidisc Optim 37(4):377–393

Hart WE, Watson JP, Woodruff DL (2011) Pyomo: modeling and solving mathematical programs in python. Math Program Comput 3(3):219–260

Hart WE, Laird CD, Watson JP, Woodruff DL, Hackebeil GA, Nicholson BL, Siirola JD (2017) Pyomo-optimization modeling in python, vol 67, 2nd edn. Springer, New York

He L, Gilbert M, Johnson T, Pritchard T (2019) Conceptual design of am components using layout and geometry optimization. Comput Math Appl 78(7):2308–2324

He L, Gilbert M, Song X (2019) A python script for adaptive layout optimization of trusses. Struct Multidisc Optim 60(2):835–847

Hirota M, Kanno Y (2015) Optimal design of periodic frame structures with negative thermal expansion via mixed integer programming. Optim Eng 16(4):767–809

Kureta R, Kanno Y (2014) A mixed integer programming approach to designing periodic frame structures with negative Poisson’s ratio. Optim Eng 15(3):773–800

Lange J, Feucht T, Erven M (2020) 3D printing with steel: additive manufacturing for connections and structures. Steel Constr 13(3):144–153

Larsen S, Sigmund O, Groen J (2018) Optimal truss and frame design from projected homogenization-based topology optimization. Struct Multidisc Optim 57(4):1461–1474

Le Corvec V (2012) Nonlinear 3D frame element with multi-axial coupling under consideration of local effects. PhD thesis, UC Berkeley

Li Y, Chen Y (2010) Beam structure optimization for additive manufacturing based on principal stress lines. In: 2010 International Solid Freeform Fabrication Symposium, University of Texas at Austin

Parkes E (1975) Joints in optimum frameworks. Int J Solids Struct 11(9):1017–1022

Prager W (1977) Optimal layout of cantilever trusses. J Optim Theory Appl 23(1):111–117

Rainer A, Giannitelli SM, Accoto D, De Porcellinis S, Guglielmelli E, Trombetta M (2012) Load-adaptive scaffold architecturing: a bioinspired approach to the design of porous additively manufactured scaffolds with optimized mechanical properties. Ann Biomed Eng 40:966–975

Reintjes C, Lorenz U (2021) Bridging mixed integer linear programming for truss topology optimization and additive manufacturing. Optim Eng 22(2):849–893

Ribeiro TP, Bernardo LF, Andrade J (2021) Topology optimisation in structural steel design for additive manufacturing. Appl Sci 11(5):2112

Schenk O, Gärtner K, Fichtner W, Stricker A (2001) Pardiso: a high-performance serial and parallel sparse linear solver in semiconductor device simulation. Future Gener Comput Syst 18(1):69–78

Shahabsafa M, Fakhimi R, Lei W, He S, Martins JR, Terlaky T, Zuluaga LF (2021) Truss topology design and sizing optimization with guaranteed kinematic stability. Struct Multidisc Optim 63(1):21–38

Smith C, Todd I, Gilbert M (2013) Utilizing additive manufacturing techniques to fabricate weight optimized components designed using structural optimization methods. In: 2013 international solid freeform fabrication symposium, University of Texas at Austin

Smith CJ, Gilbert M, Todd I, Derguti F (2016) Application of layout optimization to the design of additively manufactured metallic components. Struct Multidisc Optim 54(5):1297–1313

Sokół T (2011) A 99 line code for discretized Michell truss optimization written in mathematica. Struct Multidisc Optim 43(2):181–190

Sokół T, Rozvany G (2013) On the adaptive ground structure approach for multi-load truss topology optimization. 10th world congresses of structural and multidisciplinary optimization

Stolpe M (2007) On the reformulation of topology optimization problems as linear or convex quadratic mixed 0–1 programs. Optim Eng 8(2):163–192

Toragay O (2022) Design optimization of lightweight structures for additive manufacturing. PhD thesis, Auburn University

Toragay O, Silva DF, Vinel A, Shamsaei N (2022) Exact global optimization of frame structures for additive manufacturing. Struct Multidisc Optim 65(3):1–18

Tyburec M, Kočvara M, Kružík M (2022) Global weight optimization of frame structures with polynomial programming. arXiv:2211.14066

Van Rossum G, Drake FL (2009) Python 3 reference manual. CreateSpace, Scotts Valley

Wächter A, Biegler LT (2006) On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math Program 106(1):25–57

Wang D, Yang Y, Yi Z, Su X (2013) Research on the fabricating quality optimization of the overhanging surface in SLM process. Int J Adv Manuf Technol 65(9–12):1471–1484

Wang W, Wang TY, Yang Z, Liu L, Tong X, Tong W, Deng J, Chen F, Liu X (2013) Cost-effective printing of 3D objects with skin-frame structures. ACM Trans Graph (ToG) 32(6):1–10

Wang Y, Li S, Yu Y, Xin Y, Zhang X, Zhang Q, Wang S (2020) Lattice structure design optimization coupling anisotropy and constraints of additive manufacturing. Mater Des 196:109089

Weaver W, Gere JM (2012) Matrix analysis framed structures. Springer, New York

Weldeyesus AG, Gondzio J (2018) A specialized primal-dual interior point method for the plastic truss layout optimization. Comput Optim Appl 71(3):613–640

Weldeyesus AG, Gondzio J, He L, Gilbert M, Shepherd P, Tyas A (2019) Adaptive solution of truss layout optimization problems with global stability constraints. Struct Multidisc Optim 60(5):2093–2111

Acknowledgements

The authors are grateful to the National Center for Additive Manufacturing Excellence (NCAME) at Auburn University and especially Dr. Nima Shamsaei for the guidance and support provided.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no Conflict of interest.

Replication of results

The results that we mentioned in this paper can be replicated using the codes which are shared in the first author’s Github account https://github.com/oguztoragay/AMPAP2.8.

Additional information

Responsible Editor: Matthew Gilbert

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Toragay, O., Silva, D.F. & Vinel, A. On optimization of lightweight planar frame structures: an evolving ground structure approach. Struct Multidisc Optim 67, 79 (2024). https://doi.org/10.1007/s00158-024-03796-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-024-03796-w