Abstract

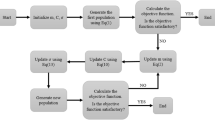

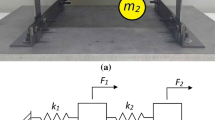

In this research, experimental vibration data in time and frequency domains are used to identify material properties in the finite element model of a car seat frame using a surrogate-based multi-objective genetic algorithm. The frame consists of several components made from different steel grades. In the first step, the Young modulus, the density, and the Poisson’s ratio of different components of the frame are identified by optimizing two objective functions based on comparing the experimental and numerical natural frequencies and mode shapes. The response surface optimization using different surrogate models and different numbers of vibration modes are performed and the best-compromised material properties are reported. In the second step of the material identification procedure, the damping coefficients of the frame’s components are estimated by comparing the experimental impulse responses with those of the FE model using the MOGA. Based on the results, the presented approach can be efficiently applied to practical problems to estimate their material properties with reasonable computational costs.

Similar content being viewed by others

Data availability

The data to reproduce the findings of this research cannot be shared publicly; however, they may be provided as per request.

References

Allemang RJ, Brown DL (2006) A complete review of the complex mode indicator function (CMIF) with applications. Proc ISMA Int Conf Noise Vibration Eng Katholieke Universiteit Leuven Belgium 2006:3209–3246

Ansys Inc., Canonsburg, PA, USA (2019) ANSYS Workbench®. ANSYS Inc.

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2(4). Taylor & Francis: 455–475.

Box GEP, Wilson KB (1951) On the experimental attainment of optimum conditions. Journal of the royal statistical society: Series b (Methodological) 13(1). Wiley Online Library: 1–38.

Bustamante L, Jeyaprakash N, Yang C-H, Tseng S-P (2021) Nondestructive characterization of mechanical properties on metallic and polymer plates using hybrid laser-air coupled ultrasonic techniques. The International Journal of Advanced Manufacturing Technology 112(5). Springer: 1767–1785.

Cai C, Zheng H, Khan MS, Hung KC (2002) Modeling of material damping properties in ANSYS. In: CADFEM Users’ Meeting & ANSYS Conference, 2002, pp 9–11.

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE transactions on evolutionary computation 6(2). IEEE: 182–197.

Ewins DJ (2009) Modal testing: theory practice and application. Wiley

Ferreira SLC, Bruns RE, Ferreira HS, et al. (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Analytica chimica acta 597(2). Elsevier: 179–186.

Imamovic N (1998) Validation of large structural dynamics models using modal test data. Department of Mechanical Engineering, Imperial College.

Johnson ME, Moore LM, Ylvisaker D (1990) Minimax and maximin distance designs. Journal of statistical planning and inference 26(2). Elsevier: 131–148.

Joseph VR (2016) Space-filling designs for computer experiments: A review. Quality Engineering 28(1). Taylor & Francis: 28–35.

Joun M-S, Eom J-G, Lee M-C, Park JH, Yoon DJ (2008) Tensile Test Based Material Identification Program AFDEX/MAT and Its Application to Two New Pre-Heat Treated Steels and a Conventional Cr-Mo steel. International Journal of Modern Physics B 22(31n32). World Scientific: 5774–5779.

Kang JS, Park S-K, Shin S, Lee HS (2005) Structural system identification in time domain using measured acceleration. Journal of sound and vibration 288(1–2). Elsevier: 215–234.

Kim K-Y, Samad A, Benini E (2019) Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical Optimization. John Wiley & Sons.

Krige DG (1960) On the departure of ore value distributions from the lognormal model in South African gold mines. Journal of the Southern African Institute of Mining and Metallurgy 61(4). Sabinet: 231–244.

Kudela P, Radzienski M, Fiborek P, Wandowski T (2020) Elastic constants identification of woven fabric reinforced composites by using guided wave dispersion curves and genetic algorithm. Composite Structures 249. Elsevier: 112569.

Lepoittevin G, Kress G (2011) Finite element model updating of vibrating structures under free--free boundary conditions for modal damping prediction. Mechanical systems and signal processing 25(6). Elsevier: 2203–2218.

Li XY, Law SS (2009) Identification of structural damping in time domain. J Sound Vibration 328(1–2). Elsevier: 71–84.

Matheron G (1963) Principles of geostatistics. Econ Geol 58(8). Soc Econ Geol: 1246–1266.

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response surface methodology: process and product optimization using designed experiments. Wiley

Nguyen V-T, Kwon S-J, Kwon O-H, Kim JS (2017) Mechanical properties identification of sheet metals by 2D-digital image correlation method. Procedia Engineering 184. Elsevier: 381–389.

Santner TJ, Williams BJ, Notz WI (2003) The design and analysis of computer experiments. Springer

Simon D (2013) Evolutionary optimization algorithms. Wiley

Sivanandam SN, Deepa SN (2008) Genetic algorithm optimization problems. In: Introduction to Genetic Algorithms. Springer, pp 165–209.

SolidWorks® (2019) Dassault systemes Inc.

Syngellakis S, Setiawan R (2013) Vibration tests and metamodelling for composite material characterization. WIT Transact Eng Sci Mater Charact VI 77:113–125

Tam JH, Ong ZC, Ismail Z, Ang BC, Khoo SY (2017) Identification of material properties of composite materials using nondestructive vibrational evaluation approaches: a review. Mechanics of Advanced Materials and Structures 24(12). Taylor & Francis: 971–986.

Tam JH, Ong ZC, Ho KW (2019) Composite material identification using a two-stage meta-heuristic hybrid approach incorporated with a two-level FRF selection scheme. J Sound Vibrat 456. Elsevier: 407–430.

Tam JH (2020) Identification of elastic properties utilizing non-destructive vibrational evaluation methods with emphasis on definition of objective functions: a review. Structural and Multidisciplinary Optimization. Springer: 1–34.

Viala R, Placet V, Cogan S (2018) Identification of the anisotropic elastic and damping properties of complex shape composite parts using an inverse method based on finite element model updating and 3D velocity fields measurements (FEMU-3DVF): Application to bio-based composite violin soundboards. Comp Part A Appl Sci Manufact 106. Elsevier: 91–103. https://doi.org/10.1016/j.compositesa.2017.12.018.

Yeh C-H, Jeyaprakash N, Yang C-H (2020) Non-destructive characterization of elastic properties on steel plate using laser ultrasound technique under high-temperature atmosphere. Int J Adv Manufact Technol 108(1). Springer: 129–141.

Yildizdag ME, Barchiesi E, dell’Isola F (2020) Three-point bending test of pantographic blocks: numerical and experimental investigation. Mathematics and Mechanics of Solids 25(10). SAGE Publications Sage UK: London, England: 1965–1978.

Funding

No funding was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Replication of results

The FE model of the car seat frame can be provided as per request.

Additional information

Responsible Editor: Axel Schumacher

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fatahi, L. Vibration-based material properties identification of a car seat frame in time and frequency domains using multi-objective genetic algorithm. Struct Multidisc Optim 65, 22 (2022). https://doi.org/10.1007/s00158-021-03136-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-021-03136-2