Abstract

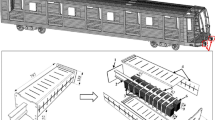

By coupling thin-walled metal and aluminium honeycomb structures, a composite energy-absorbing structure with a high strength to weight ratio was designed. The validity of equivalent models of the thin-walled metal structure and the aluminium honeycomb was separately verified by carrying out trolley impact and quasi-static compression tests. The polynomial response surface models (PRSMs) of specific energy absorption (SEA) and initial peak force (F ip) during a collision were respectively established based on an orthogonal experimental design (OED) and the polynomial response surface method. The precisions of the three PRSMs were, in descending order, quartic, cubic, and quadratic PRSM (PRSM-4 > PRSM-3 > PRSM-2) as found by error analysis. The three PRSMs were separately optimised by using single-objective particle swarm optimisation (SOPSO) and the optimal values of SEA and F ip within the design range obtained from the PRSM-4 were respectively 33.5224 kJ/kg and 231.6860 kN among these PRSMs. The relative errors between the above optimal results of the PRSM-4, and the results obtained by numerical simulation, were 0 and −0.67%, respectively. Moreover, a Pareto front of double optimisation objective SEA and F ip was obtained after being optimised by multi-objective particle swarm optimisation (MOPSO), and SEA max was 33.0936 kJ/kg (the maximum SEA) and \( {F}_{{\mathrm{ip}}_{\mathrm{min}}} \) was 232.3510 kN (the minimum F ip) as separately obtained by using the PRSM-4. The errors between the above results and those (SEA = 33.5224 kJ/kg and F ip = 233.2406 kN) obtained through numerical simulation were separately 1.28% and −0.38%, which also indicates that the optimisation result is reliable.

Similar content being viewed by others

References

Abedrabbo N, Mayer R, Thompson A, Salisbury C, Worswick M, van Riemsdijk I (2009) Crash response of advanced high-strength steel tubes: experiment and model. Int J Impact Eng 36(8):1044–1057

Alavi Nia A, Parsapour M (2013) An investigation on the energy absorption characteristics of multi-cell square tubes. Thin-Walled Struct 68:26–34

Azaza M, Wallin F (2017) Multi objective particle swarm optimization of hybrid micro-grid system: a case study in Sweden. Energy 123:108–118

Biqiang Z, Xiaodong L, Yajun Z (2016) The structure optimization analysis of electric vehicle in small offset rear end collision. Procedia Engineering 137:103–108

Duddeck F, Hunkeler S, Lozano P, Wehrle E, Zeng D (2016) Topology optimization for crashworthiness of thin-walled structures under axial impact using hybrid cellular automata. Struct Multidiscip Optim 54:415–428

Gao GJ, Tian HQ (2007) Train's crashworthiness design and collision analysis. Int J Crashworthiness 12(1):21–28

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Hallquist JO (2006) LS-DYNA theory manual. Livermore Software Technology Corporation, California

Hong ST, Pan J, Tyan T, Prasad P (2006) Quasi-static crush behavior of aluminum honeycomb specimens under compression dominant combined loads. Int J Plast 22(1):73–109

Karagoz S, Yildiz AR (2017) A comparison of recent metaheuristic algorithms for crashworthiness optimisation of vehicle thin-walled tubes considering sheet metal forming effects. Int J Veh Des 73(1/2/3):179–188

Khalkhali A, Mostafapour M, Tabatabaie SM, Ansari B (2016) Multi-objective crashworthiness optimization of perforated square tubes using modified NSGAII and MOPSO. Struct Multidiscip Optim 54(1):45–61

Kiani M, Yildiz AR (2016) A comparative study of non-traditional methods for vehicle crashworthiness and NVH optimization. Arch Comput Meth Eng 23(4):723–734

Li J, Gao G, Dong H, Xie S, Guan W (2016a) Study on the energy absorption of the expanding–splitting circular tube by experimental investigations and numerical simulations. Thin-Walled Struct 103:105–114

Li C, Xiao Q, Tang Y, Li L (2016b) A method integrating Taguchi, RSM and MOPSO to CNC machining parameters optimization for energy saving. J Clean Prod 135:263–275

Ling L, Dhanasekar M, Thambiratnam DP (2017) Frontal collision of trains onto obliquely stuck road trucks at level crossings: derailment mechanisms and simulation. Int J Impact Eng 100:154–165

Liu Q, Xu X, Ma J, Wang J, Shi Y, Hui D (2017a) Lateral crushing and bending responses of CFRP square tube filled with aluminum honeycomb. Compos Part B 118:104–115

Liu G, Xie J, Xie S (2017b) Experimental and numerical investigations of a new U-shaped thin plate energy absorber subjected to bending and friction. Thin-Walled Struct 115:215–224

Peng Y, Deng W, Xu P, Yao S (2015) Study on the collision performance of a composite energy-absorbing structure for subway vehicles. Thin-Walled Struct 94:663–672

Perez RE, Behdinan K (2007) Particle swarm approach for structural design optimization. Comput Struct 85(19–20):1579–1588

Pholdee N, Bureerat S (2017) Hybrid real-code population-based incremental learning and differential evolution for many-objective optimisation of an automotive floor-frame. Int J Veh Des 73(1/2/3):20–53

Song X, Sun G, Li G, Gao W, Li Q (2013) Crashworthiness optimization of foam-filled tapered thin-walled structure using multiple surrogate models. Struct Multidiscip Optim 47(2):221–231

Sun G, Li S, Liu Q, Li G, Li Q (2016) Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes. Compos Struct 152:969–993

Sun G, Zhang H, Lu G, Guo J, Cui J, Li Q (2017a) An experimental and numerical study on quasi-static and dynamic crashing behaviors for tailor rolled blank (TRB) structures. Mater Des 118:175–197

Sun G, Pang T, Xu C, Zheng G, Song J (2017b) Energy absorption mechanics for variable thickness thin-walled structures. Thin-Walled Struct 118:214–228

Sun G, Zhang H, Fang J, Li G, Li Q (2017c) Multi-objective and multi-case reliability-based design optimization for tailor rolled blank (TRB) structures. Struct Multidiscip Optim 55(5):1899–1916

Sun G, Pang T, Fang J, Li G, Li Q (2017d) Parameterization of criss-cross configurations for multiobjective crashworthiness optimization. Int J Mech Sci 124-125:145–157

Vinayagar K, Senthil Kumar A (2017) Crashworthiness analysis of double section bi-tubular thin-walled structures. Thin-Walled Struct 112:184–193

Wang Z, Tian H, Lu Z, Zhou W (2014) High-speed axial impact of aluminum honeycomb – experiments and simulations. Compos Part B 56:1–8

Wang Z, Yao S, Lu Z, Hui D, Feo L (2016) Matching effect of honeycomb-filled thin-walled square tube—experiment and simulation. Compos Struct 157:494–505

Wu S, Zheng G, Sun G, Liu Q, Li G, Li Q (2016) On design of multi-cell thin-wall structures for crashworthiness. Int J Impact Eng 88:102–117

Wu Y, Liu Q, Fu J, Li Q, Hui D (2017) Dynamic crash responses of bio-inspired aluminum honeycomb sandwich structures with CFRP panels. Compos Part B. https://doi.org/10.1016/j.compositesb.2017.03.030

Xie S, Zhou H (2014) Impact characteristics of a composite energy absorbing bearing structure for railway vehicles. Compos Part B 67:455–463

Xie S, Zhou H (2015) Analysis and optimisation of parameters influencing the out-of-plane energy absorption of an aluminium honeycomb. Thin-Walled Struct 89:169–177

Xie S, Liang X, Zhou H, Li J (2016) Crashworthiness optimisation of the front-end structure of the lead car of a high-speed train. Struct Multidiscip Optim 53(2):339–347

Xu P, Yang C, Peng Y, Yao S, Zhang D, Li B (2016a) Crash performance and multi-objective optimization of a gradual energy-absorbing structure for subway vehicles. Int J Mech Sci 107:1–12

Xu P, Yang C, Peng Y, Yao S, Xing J, Li B (2016b) Cut-out grooves optimization to improve crashworthiness of a gradual energy-absorbing structure for subway vehicles. Mater Des 103:132–143

Yildiz AR (2013) Comparison of evolutionary-based optimization algorithms for structural design optimization. Eng Appl Artif Intell 26(1):327–333

Yildiz BS (2017) A comparative investigation of eight recent population-based optimisation algorithms for mechanical and structural design problems. Int J Veh Des 73(1/2/3):208–218

Yildiz BS, Lekesiz H (2017) Fatigue-based structural optimisation of vehicle components. Int J Veh Des 73(1/2/3):54–62

Yildiz AR, Saitou K (2011) Topology synthesis of multicomponent structural assemblies in continuum domains. J Mech Des 133:1–9

Yildiz AR, Solanki KN (2012) Multi-objective optimization of vehicle crashworthiness using a new particle swarm based approach. Int J Adv Manuf Technol 59(1–4):367–376

Yildiz AR, Kurtulus E, Demirci E, Betul YS, Karagoz S (2016a) Optimization of thin-wall structures using hybrid gravitational search and Nelder-mead algorithm. Materials Testing 58(1):75–78

Yildiz BS, Lekesiz H, Yildiz AR (2016b) Structural design of vehicle components using gravitational search and charged system search algorithms. Materials Testing 58(1):79–81

Zeng D, Duddeck F (2017) Improved hybrid cellular automata for crashworthiness optimization of thin-walled structures. Struct Multidiscip Optim 56(1):101–115

Zhang X, Jin X, Qi W, Guo Y (2008) Vehicle crash accident reconstruction based on the analysis 3D deformation of the auto-body. Adv Eng Softw 39(6):459–465

Zhong ZH (1993) Finite element procedures for contact-impact problems. Oxford University Press, Oxford, pp 96–213

Zhu G, Wang Z, Huo X, Cheng A, Li G, Zhou C (2017) Experimental and numerical investigation into axial compressive behaviour of thin-walled structures filled with foams and composite skeleton. Int J Mech Sci 122:104–119

Acknowledgements

This research was undertaken at the Key Laboratory for Traffic Safety on Track of the Ministry of Education, Central South University, China. The authors gratefully acknowledge the support from the National Natural Science Foundation of China (Grant nos. 51775558, 51405516) and the support from the Shenghua Yu-ying Talents Program of the Central South University (Principle Investigator: Prof. Suchao Xie).

Author information

Authors and Affiliations

Corresponding author

Appendix: The response model expressions

Appendix: The response model expressions

Rights and permissions

About this article

Cite this article

Xie, S., Li, H., Yang, W. et al. Crashworthiness optimisation of a composite energy-absorbing structure for railway vehicles. Struct Multidisc Optim 57, 1793–1807 (2018). https://doi.org/10.1007/s00158-017-1829-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-017-1829-7