Abstract

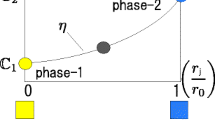

Based on discrete material optimization and topology optimization technologies, this paper discusses the problem of integrated optimization design of the material and structure of fiber-reinforced composites by considering the characteristics of the discrete variable of fiber ply angle because of the manufacture requirements. An optimization model based on the minimum structural compliance with a specified composite volume constraint is established. The ply angle and the distribution of the composite material are introduced as independent variables in two geometric scales (material and structural scales). The void material is added into the optional discrete material set to realize the topology change of the structure. This paper proposes an improved HPDMO (Heaviside Penalization of Discrete Material Optimization) model to obtain a better convergent result, and an explicit sensitivity analysis is performed. The effects of the HPDMO model on the convergence rate of the optimization results, the objective function value and the iteration history are studied and compared with those from the classical Discrete Material Optimization model and the Continuous Discrete Material Optimization model in this paper. Numerical examples in this paper show that the HPDMO model can effectively achieve the integrated optimization of the fiber ply angle and its distribution in the structural domain, and can also considerably improve the convergence rate of the optimal results compared with other DMO models. This model will help to reduce the manufacture cost of the optimal design.

Similar content being viewed by others

References

Banichuk NV, Karihaloo BL (1976) Minimum-weight design of multipurpose cylindrical bars. Int J Solids Struct 12(4):267–273

Bendsoe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bendsoe M, Sigmund O (2003) Topology optimization-theory, methods and applications. Springer, Berlin

Bruyneel M (2011) SFP-a new parameterization based on shape functions for optimal material selection: application to conventional composite plies. Struct Multidiscip Optim 43(1):17–27

Callahan KJ, Weeks GE (1992) Optimum design of composite laminates using genetic algorithms. Compos Eng 2(3):149–160

Deaton JD, Grandhi RV (2014) A survey of structural and multidisciplinary continuum topology optimization: post 2000. Struct Multidiscip Optim 49(1):1–38

Eschenauer HA, Olhoff N (2001) Topology optimization of continuum structures a review. Am Soc Mech Eng 54(4):331–390

Ferreira HTL, Rodrigues HC, Guedes JM, Hernandes JA (2013) Hierarchical optimization of laminated fiber reinforced composites. In: Proceedings of 10th word congress on structural and multidisciplinary optimization Orlando, Florida, USA, May 19–24

Froes FH, Suryanarayana C, Eliezer D (1992) Synthesis, properties and applications of titanium aluminides. J Mater Sci 27(19):5113–5140

Gao T, Zhang W (2011) A mass constraint formulation for structural topology optimization with multiphase materials[J]. Int J Numer Methods Eng 88(8):774–796

Gao T, Zhang W, Duysinx P (2012) A bi-value coding parameterization scheme for the discrete optimal orientation design of the composite laminate. Int J Numer Methods Eng 91(1):98–114

Graesser DL, Zabinsky ZB, Tuttle ME, Kim GI (1991) Designing laminated composites using random search techniques. Compos Struct 18(4):311–325

Guest JK (2009) Imposing maximum length scale in topology optimization. Struct Multidiscip Optim 37(5):463–473

Guest JK, Prevost JH, Belytschko T (2004) Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Int J Numer Methods Eng 61(2):238–254

Guest JK, Asadpoure A, Ha SH (2011) Eliminating beta-continuation from Heaviside projection and density filter algorithms. Struct Multidiscip Optim 44(4):443–453

Hao Z (2002) Applications and prospects of magnesium and its alloys in aerospace. Aviat Eng Maint 04:41–42

Hvejsel CF, Lund E (2011) Material interpolation schemes for unified topology and multi-material optimization. Struct Multidiscip Optim 43(6):811–825

Lund E (2009) Buckling topology optimization of laminated multi-material composite shell structures. Compos Struct 91(2):158–167

Lund E, Stegmann J (2005) On structural optimization of composite shell structures using a discrete constitutive parametrization. Wind Energy 8(1):109–124

Nagendra S, Jestin D, Gurdal Z, Haftka RT, Watson LT (1996) Improved genetic algorithm for the design of stiffened composite panels. Comput Struct 58(3):543–555

Niu B, Olhoff N, Lund E, Cheng G (2010) Discrete material optimization of vibrating laminated composite plates for minimum sound radiation. Int J Solids Struct 47(16):2097–2114

Park JH, Hwang JH, Lee CS, Hwang W (2001) Stacking sequence design of composite laminates for maximum strength using genetic algorithms. Compos Struct 52(2):217–231

Pelletier JL, Vel SS (2006) Multi-objective optimization of fiber reinforced composite laminates for strength, stiffness and minimal mass. Comput Struct 84(29–30):2065–2080

Powell MJD (1978) Algorithms for non-linear constraints that use lagrangian functions. Math Program 14(2):224–248

Rozvany GIN, Zhou M, Birker T (1992) Generalized shape optimization without homogenization. Struct Optim 4(3–4):250–252

Du S (2007) Advanced composite materials and aerospace engineering. Acta Mater Compositae Sin 1(24):1–12

Sigmund O (2007) Morphology-based black and white filters for topology optimization. Struct Multidiscip Optim 33(4–5):401–424

Sigmund O, Maute K (2013) Topology optimization approaches. Struct Multidiscip Optim 1–25

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62(14):2009–2027

Weck M, Steinke P (1983) An efficient technique in shape optimization. J Struct Mech 11(4):433–449

Xu S, Cai Y, Cheng G (2010) Volume preserving nonlinear density filter based on Heaviside functions. Struct Multidiscip Optim 41(4):495–505

Acknowledgments

The financial support for this research was provided by the Program (11372060, 91216201) of the NSFC, the National Basic Research Program of China (2011CB610304), the Major National Science and Technology Project (2011ZX02403-002), 111 project (B14013), Fundamental Research Funds for the Central Universities (DUT14LK30) and the China Scholarship Fund. These supports are greatly appreciated.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Duan, Z., Yan, J. & Zhao, G. Integrated optimization of the material and structure of composites based on the Heaviside penalization of discrete material model. Struct Multidisc Optim 51, 721–732 (2015). https://doi.org/10.1007/s00158-014-1168-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-014-1168-x