Abstract

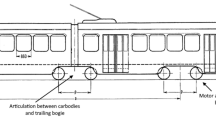

This paper extends classical structural optimization from single-product optimization to optimization of a whole family of products that have common modules. It integrates the family commonality problem with the finite element models of the structures. A general mathematical frame where optimization is seen as a balance between cost and performance is given. The most obvious cost function is mass, while performance is taken to be a weighted sum of compliances. As a case study, a car product family consisting of three products is presented. These three products are a base model, a seven-seat version, and a pickup version. The study shows how optimal results are effected by requiring modules to be shared between products. Loads emanating from prescribed acceleration fields that simulate crash situations are used. This is a proof-of-concept paper which is a first step toward including more general manufacturing costs than mass and performance measures other than compliance.

Similar content being viewed by others

References

Cetin OL, Saitou K, Nishiwaki S, Tsurumi Y (2002) Modular structural component design using the decomposition-based assembly synthesis. In: The 10th International conference on machine design and production, Cappadocia, Turkey, 4–6 September

Cook RD, Malkus DS, Plesha ME, Witt RJ (2002) Concept and applications of finite element analysis, 4th edn. Wiley, New York

Fellini R, Kokkolares M, Michelena N, Papalambros P, Perez-Duarte A, Saitou K, Fenyes P (2004) A sensitivity-based commonality strategy for family products of mild variation, with application to automotive body structures. Struct Multidisc Optim 27:89–96

Fredicson H, Johansen T, Klarbring A, Petersson J (2003) Topology optimization of frame structures with flexible joints. Struct Multidisc Optim 25:199–214

Gupta S, Das D, Regli WC, Nau DS (1997) Automated manufactur ability: a survey. Res Eng Des 9(3):168–190

Kikuchi N et al (2001) Modular structural component design using the first order analysis and decomposition-based assembly synthesis. In: ASME international mechanical engineering congress and exposition, New York, USA, 11–16 November

Kikuchi N et al (2004) First order analysis for automotive body structure design. In: 2004 SAE world congress, Detroit, USA, 8–11 March

Meyer MH, Lehnerd AP (1997) The power of product platforms. Free Press, New York

Raasch I (2004) Sizing in conceptual design at BMW. In: SAE world congress, Detroit, USA, 8–11 March

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Torstenfelt B (1995) TRINITAS’ finite element learning studio. http://www.solid.ikp.liu.se/botor/Prog/Executables.html

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torstenfelt, B., Klarbring, A. Structural optimization of modular product families with application to car space frame structures. Struct Multidisc Optim 32, 133–140 (2006). https://doi.org/10.1007/s00158-005-0568-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-005-0568-3