Abstract

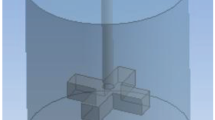

In this study, the advantages of the vortex melting reduction treatment of red mud were verified. Vortex melting reduction can improve the feeding rate, promote the reaction and the directional deposition of iron, which was conducive to the separation of slag and gold. The effects of different adding methods, stirring speed and reaction time on iron recovery were investigated by using red mud, aluminum leached slag and calcified slag as raw materials. According to the experiment, the best reaction conditions were that the raw material put into the furnace by rolling pellets, stirring speed 125 RPM, and reaction time 30 min. The results provided an experimental basis for the harmless and high-value utilization of high-iron red mud treated by vortex melting reduction.

Similar content being viewed by others

References

Chenna RB, Yiannis P, Koen B (2015) Tom Van Gerven. Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27

Erol E, Reşat A (1997) Furnace smelting and extractive metallurgy of red mud: recovery of TiO2, Al2O3 and pig iron. J Chem Technol Biotechnol 70(3):241–246

Gostu S, Mishra B, Martins GP (2017) Low temperature reduction of hematite in red mud to magnetite. The minerals, metals & materials society. Springer, Cham, pp 67–73

Gräfe M, Power G, Klauber C (2011) Bauxite residue issues: III. Alkalinity and associated chemistry. Hydrometallurgy 108:60–79

Guan JH (2000) Study on recovering Fe from red mud with SLon vertical ring and pulsating high gradient magnetic separator. Jiangxi Nonferrous Metals 14(4):15–18

Haikou Customs P. R. China (2021) Online data inquiry platform of the General Administration of Customs. http://www.customs.gov.cn/haikou_customs/605737/fdzdgknr82/605745/3539138/index.html. Accessed 26 November 2021

He GW (2015) An overview of the world’s bauxite resources. Technol Outlook 25(09):228

He P, Ju DC, Shen PF et al (2017) Experimental research on comprehensive utilization of red mud based on direct reduction and melting by RHF iron bead technology. Energy Metall Ind 36(04):57–60

Hu W, Xiong DH (2010) On iron ore recovery out of mineral processing tailing and smelting tailing by magnetic-gravity process. Nonferrous Met Sci Eng 1(3):52–54

Jayasankar K, Ray PK, Chaubey AK (2012) Production of pig iron from red mud waste fines using thermal plasma technology. Int J Minerals Metall Mater 19(08):679–684

K Ma, Jafar Z, Behdad M (2019) The composition, recycling and utilisation of Bayer red mud. Resour Conserv Recycling 141:483–498

Ke WS, Zhang XC, Zhu F et al (2021) Appropriate human intervention stimulates the development of microbial communities and soil formation at a long-term weathered bauxite residue disposal area. J Hazard Mater 405:124689

Klauber C, Gräfe M, Power G (2011) Bauxite residue issues: II. Options for residue utilization. Hydrometallurgy 108(1):11–32

Li Y, Wang J, Wang X et al (2011) Feasibility study of iron mineral separation from red mud by high gradient superconducting magnetic separation. Physica C 471(3/4):91–96

Liu ZB, Li HX (2015) Metallurgical process for valuable elements recovery from red mud—a review. Hydrometallurgy 155:29–43

Liu YT, Qin ZH, Chen B (2020) Experimental research on magnesium phosphate cements modified by red mud. Constr Build Mater 231:117–131

Lü CS, Wang JW, Jia YZ (2013) Effects of red mud content on the sintered red mud bricks. J Saf Environ 13:98–102

Lu GZ, Zhang TA, Zhu XF et al (2014) Calcification–carbonation method for cleaner alumina production and CO2 utilization. JOM 66(9):1616–1621

Mei XG, Yuan ML, Zuo WL et al (1994) Studies on the nucleation and grain growth characteristics of metallic phase in direct reduction of high-iron red mud with coal base. J Central-South Inst Min Metall 06:696–700

Menzies NW, FultonI M, Morrell WJ (2004) Seawater neutralization of alkaline bauxite residue and implications for revegetation. J Environ Qual 33(5):1877–1884

Pepper RA, Couperthwaite SJ, Millar GJ (2016) Comprehensive examination of acid leaching behaviour of mineral phases from red mud: recovery of Fe, Al, Ti, and Si. Miner Eng 9:8–18

Ruyters S, Mertens J, Vassilieva E (2011) The red mud accident in ajka (hungary): plant toxicity and trace metal bioavailability in red mud contaminated soil. Environ Sci Technol 45(4):1616–1622

Sadangi JK, Das SP, Tripathy A et al (2018) Investigation into recovery of iron values from red mud dumps. Sep Sci Technol 53:1–6

Samouhos M, Taxiarchou M, Tsakiridis PE et al (2013) Greek “red mud” residue: a study of microwave reductive roasting followed by magnetic separation for a metallic iron recovery process. J Hazard Mater 254/255:193–205

Samouhos M, Taxiarchou M, Pilatos G et al (2017) Controlled reduction of red mud by H2 followed by magnetic separation. Miner Eng 105:36–43

Wang JS, Liu J, Xue QG (2013) Experimental research on comprehensive utilization of the high iron red mud based on direct reduction and melting by RHF iron bead technology. Light Metals 1:19–22

Wang YX, Zhang TA, Lu GZ et al (2017) Application of tricalcium aluminate instead of lime for the recovery of aluminum in middle-low grade bauxite in calcification-carbonization process. Light Metals. https://doi.org/10.1007/978-3-319-51541-0_9

Wang K, Liu Y, Zhang TA et al (2020) Investigation of the smelting reduction mechanism and of iron extraction from high-iron red mud. J Mater Res Express 7:126514

Xue SG, Liu Z, Fan JR et al (2022) Insights into variations on dissolved organic matter of bauxite residue during soil-formation processes following 2-year column simulation. Environ Pollut 292:118326

Yang Y, Wang X, Wang M et al (2015) Recovery of iron from red mud by selective leach with oxalic acid. Hydrometallurgy 157:239–245

Yu Z, Shi Z, Chen Y et al (2012) Red-mud treatment using oxalic acid by UV irradiation assistance. Trans Nonferrous Met Soc China 22:456–460

Zhang R, Zheng S, Ma S et al (2011) Recovery of alumina and alkali in Bayer red mud by the formation of andradite-grossular hydrogarnet in hydrothermal process. J Hazard Mater 189(3):827–835

Zhang TA, Wang YX, Dou ZH et al (2019) A method of direct cementation from high-iron red mud after dealkalization and iron extraction by vortex smelting reduction. China National Intellectual Property Office (Application No. CN201910290643.7)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51874078). The Fundamental Research Funds for the Central Universities of China (Grant No. N2025038).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Zhang, Ta., Wang, K. et al. Experimental Research on Vortex Melting Reduction of High-Iron Red Mud (Bauxite Residue). Bull Environ Contam Toxicol 109, 155–162 (2022). https://doi.org/10.1007/s00128-022-03501-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-022-03501-x