Abstract

In this study, 10 mosquito coils manufactured in China were obtained in Suriname, South America, where they are used extensively. The coils were analyzed for organics (allethrin, permethrin, and butylated hydroxytoluene) and heavy metals (Cr, Co, As, Cd, and Pb) by GC-MS and ICP-MS, respectively. Allethrin was the only target organic compound detected in all mosquito coils with concentrations ranging from ~1900 to ~4500 µg/g. The concentrations of heavy metals varied as follows (in µg/g): Cr: 2.9–9.4, Co: 0.1–1.2, Cu: 0.7–16.1, Se: 0.10–0.4, Ni: 2.1–5.8, As: 0.10–2.2, Cd: 0.10–0.2, and Pb: 1.1–3.6.

Similar content being viewed by others

Mosquito coils are widely used in the developing world to repel and kill mosquitoes. Repelling these insects is important in order to decrease mosquito-borne pathogenic diseases such as dengue fever, yellow fever, malaria, chikungunya, and Zika virus (Lawrance and Croft 2004; Ogoma et al. 2012). Mosquitoes (Aedes aegypti and A. albopictus) are the common vectors for the viral diseases dengue fever, chikungunya, and Zika. Recent emergence of chikungunya and human fetal developmental concerns regarding Zika are especially problematic in Caribbean and Latin American countries. Therefore, mosquito coils are a common and effective tool for killing and repelling mosquitoes. It should be noted that these burning insecticides are recommended for outdoor use. In many countries with endemic mosquito-borne diseases mosquito coils are often used indoors.

Mosquito coils generally contain a pyrethroid insecticide such as d-cis trans-allethrin with typical concentrations of 0.25 % of the active ingredient. The remaining ingredients are usually listed as “other.” Chemical analyses of mosquito coils and emissions from mosquito coils indicate a number of other chemicals. These can be part of the chemical make-up of the coil itself or are produced during the combustion of the coil. Burning the coil also produces particulates (Lin and Shen 2005; Liu et al. 1987, 2003; Chang and Lin 1998; Lee and Wang 2006; Shu-Chen et al. 2008; Roy et al. 2009; Zhang et al. 2010; Phal 2011; Singh et al. 2012; Dubey et al. 2014; Yang et al. 2015). Heavy metals such as lead have been reported in the low parts per million range (1–5 ppm) in coils that have been tested (Phal 2011).

There are major gaps in knowledge regarding their use, including their use in the tropical South American country, Suriname. These include the location(s) where they are used, the frequency with which they are used inside homes, the duration of their use primarily inside homes, ventilation rates in homes where they are used, and general cleaning habits.

While mosquito coils are a low cost method for mitigating mosquito-borne diseases, the coils themselves pose an additional health hazard for humans and pets because they are often burned inside the home despite manufacturers’ directions not to do so (Lawrance and Croft 2004). By design, mosquito coils release a considerable amount of ultrafine to fine particulate matter (PM) which may deposit in the lungs. This PM contains heavy metals as well as organic chemicals of concern (Chang and Lin 1998; Dubey et al. 2014; Lee and Wang 2006; Yang et al. 2012). Exposure to PM and its associated chemicals may contribute to acute and chronic respiratory diseases, such as pneumonia and asthma, as well as to various toxic chemical responses (Lin and Shen 2005; Liu et al. 2003, 1987; Roy et al. 2009; Shu-Chen et al. 2008; Singh et al. 2012). Burning coils indoors especially in poorly ventilated areas is likely the biggest problem associated with possible health hazards resulting from their use.

Pyrethroids are toxic to terrestrial invertebrates (Cox and Wilson 1984; Desneux et al. 2007; Palmquist et al. 2012), aquatic invertebrates (Anderson 1982; Samsoe-Petersen et al. 2001; Morolli et al. 2006), and fish with toxicity reported at very low concentrations (Palmquist et al. 2012; DeMicco et al. 2010). As examples, deltamethrin, cypermethrin, cyhalothrin, permethrin, and bifenthrin were toxic to young zebrafish at concentrations of 1, 1, 10, 50, and 100 µg/L following 6 day post fertilization exposures (DeMicco et al. 2010). Studies such as Rice at al. 1997; Kim et al. 2008; Floyd et al. 2008 and many others have also reported toxicity of pyrethroids exposed to fish. Therefore, if mosquito coils are not appropriately used for outdoor purposes, they can pose risks to both terrestrial and aquatic organisms.

While many studies have investigated the elemental and organic chemical composition of smoke from mosquito coils (e.g. Lin and Shen 2005; Liu et al. 1987, 2003; Chang and Lin 1998; Lee and Wang 2006; Shu-Chen et al. 2008; Roy et al. 2009; Zhang et al. 2010; Phal 2011; Singh et al. 2012; Dubey et al. 2014; Yang et al. 2015), very limited studies have analyzed the chemical composition of mosquito coils (e.g. Liu et al. 1987; Phal 2011). Further studies on the chemical analysis of mosquito coils are important in learning what chemicals manufacturers are adding into the coils that might contribute to human and environmental risks from the burning of the coils.

In the present study, the chemical composition (organics and heavy metals) of 10 different mosquito coils manufactured in China and obtained commercially in Suriname were analyzed. The main objectives were to identify and quantify select chemicals that may have been added to the mosquito coils during manufacture and also to determine the levels of the heavy metals in coils that are ultimately intended for indoor use in Suriname. Because it was suspected that manufacturers of mosquito coils do not list all ingredients in the mosquito coils on the chemical analysis reports, we analyzed for the active ingredients and other compounds that we thought could be used in mosquito coils.

Materials and Methods

The mean import of mosquito coils in Suriname between 2005 and 2014 was 17 million boxes (10 coils/box) per annum, indicating a high level of use of mosquito coils in this country with a population of approximately 500,000 people. The mosquito coils used in this study were randomly selected from an imported batch of 277,200 boxes at an importer’s storehouse. The mosquito coil samples were shipped to Texas Tech University where chemical analysis was performed.

Allethrin, permethrin, and dibutyl phthalate (used as recovery standard) were purchased from AccuStandard (New Haven, CT). Butylated hydroxytoluene (used as an antioxidant in insecticides) was purchased from Sigma Aldrich (St. Louis, MO), while fluoranthene-D10 (used as internal standard) was purchased from Chem Service Inc. (West Chester, PA).

All standards were individually dissolved in acetone and then mixed to make calibration standards of concentrations ranging from 2.5 to 25 mg/L.

The mosquito coils were numbered from 1 to 10 for laboratory identification (Table 1). All mosquito coils were weighed and their diameters measured before extraction and analysis. The coils ranged between 9.0 and 13.7 cm in diameter, and weighed between 8.5 and 41.5 g (Table 1). A segment weighing ~3.0 g was broken off from one end of each coil and ground into a fine powder using a mortar and pestle. The sample was then placed into a glass container wrapped in aluminum foil to ensure they received no exposure to light.

The extraction procedure used in this study was based on previous work by Yan et al. (2010). Approximately 50 mg of powder were weighed and placed in a 15 mL centrifuge tube. Then, 90 μL of a 100 µg/g dibutyl phthalate solution was then spiked on the coil powder in the tube to serve as a recovery standard, and the solvent was then allowed to volatilize. Once the solvent had volatilized, each sample tube was briefly vortexed to ensure good mixing. This was followed by the addition of 3 mL of acetone and vortex mixing for approximately 1 min. When all samples had been vortexed, they were sonicated for 5 min, and then vortexed for approximately 1 min once again. The samples were then centrifuged at 3000 rpm for 15 min. The supernatant of each sample was filtered into new 15 mL centrifuge tubes using 0.45 μm PFTE filters. Using a volumetric pipette, 400 μL of filtrate was transferred into a 1 mL GC vial. Then, 20 μL of a 200 mg/L fluoranthene-D10 internal standard solution was added to each sample. The samples were then diluted to 1 mL with 580 μL of acetone and then analyzed on the GC-MS.

In order to assess the reproducibility of the extraction procedure, segments of the middle and second end of Coils #5 and #10 were also ground and extracted using the procedure outlined above. Therefore, three replicates were performed for the extraction of Coils #5 and #10, while only one sample was extracted from the rest of the coils. The average percent recovery of dibutyl phthalate for the different segments of Coil #5 was 96.4 ± 13.7 %, while that for Coil #10 was 115.3 ± 1.8 %. This demonstrates that reproducible recoveries could be obtained with this extraction procedure.

Chemical analysis was performed using an Agilent 6890/5973 GC-MS system equipped with a 7693 auto liquid sampler (Agilent) and a ZB5 column (Phenomenex, Torrance, CA). UHP helium carrier gas was used, and the column flow rate was 1.5 mL/min. The injector and detector temperatures were 250 and 230°C, respectively. The oven program was as follows; initial temperature of 100°C held for 2 min, followed by a ramp rate of 25°C/min to 150°C, followed by 3°C/min to 200°C, followed by 8°C/min to 280°C and held for 4 min.

Laboratory blanks were analyzed to ensure that there was no contamination in the lab during sample preparation. Two method blanks were analyzed and no target analytes were detected. Instrument blanks were also analyzed and no carryover of any target analyte was observed during GC-MS analysis.

A method adapted from EPA 200.3 (McDaniel 1991) was used to prepare the mosquito coils for heavy metal analysis using an Agilent 7500c ICP-MS. After the samples were ground into a fine powder, 0.25 g was added to a 100 mL beaker along with 5 mL of nitric acid and 2.5 mL of hydrochloric acid. Samples were heated for approximately 3 h and then allowed to cool to room temperature. Then 5 mL of hydrogen peroxide was added and the sample was left at room temperature for approximately 2 h. The samples were heated a second time for approximately 3 h. Finally, samples were diluted to 50 mL using 18 MΩ water and centrifuged prior to analysis.

Blank samples were prepared as explained above, without adding sample, to verify there was no contamination during the digestion process. A freeze-dried mussel tissue standard reference material (SRM 2976) purchased from NIST (Gaithersburg, MD) was prepared to confirm the digestion process was working and that the instrument was performing well. Two duplicate samples were prepared to evaluate within-sample variability. Coil #10 was ground into three separate samples (both ends and the middle) to verify that variation throughout the coil was low. Continuing calibration verification samples (CCVs) were run every eight samples to ensure that the calibration curve remained within an acceptable range. All CCVs for the eight elements examined (Cr, Co, As, Cd, Ni, Cu, Se, and Pb) were within 10 % of the known concentration, which is considered acceptable according to EPA method 6020A (US EPA 1998). The calculated method detection limit (MDL) was determined by analyzing seven replicates of a blank sample. The MDLs for Cr, Co, As, Cd, Ni, Cu, Se, and Pb were 1.3, 0.10, 0.10, 0.10, 0.60, 0.70, 0.20, and 0.40 ng/g, respectively. Instrument blanks consisting of 2 % nitric acid and 1 % hydrochloric acid were used to ensure there was no carryover during analysis.

Results and Discussion

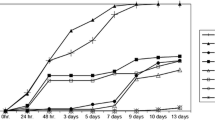

Allethrin levels ranged from ~0.19 % to 0.45 % (Fig. 1, geometric mean of 0.26 %). This appears to be consistent with other manufacturers and with what has been reported. We do not have information on tolerable ranges from the manufacturer or minimally effective concentrations.

Elemental levels of Pb, Ni, Se, Cu, Cd, Cr, Co, and As are shown in Table 2, and are consistent with those reported by a different study (Phal 2011). Lead levels in the tested coils were in the low µg/g range (geometric mean of 2.44 µg/g, 95 % CI 1.91–3.13 µg/g).

Based on the elemental analysis of the coils tested, the concentrations of Cr (2.9–9.4 µg/g), Pb (1.1–3.6 µg/g), and Ni (2.1–5.8 µg/g) were in good agreement with those from a different source in a study by Phal (2011) with average concentrations of 7.3, 2.1, and 3.1 µg/g for Cr, Pb, and Ni, respectively. On the other hand, the average concentrations of Cd (<0.05 µg/g) and As (<0.01 µg/g) reported in the Phal (2011) study were quite lower than those obtained in this study, i.e. 0.10 –0.16 µg/g and 0.10–2.18 µg/g for Cd and As, respectively. In the Phal (2011) study, an ICP-OES was used to analyze the heavy metals in the mosquito coils, whereas an ICP-MS was used in the present study. Because of the lower sensitivity of the ICP-OES compared to the ICP-MS, it is possible that the concentrations of Cd and As in the Phal (2011) study were very close to the detection limit, thus hindering accurate quantitation of these metals, while the ICP-MS used in this study gave us the advantage of being able to detect such low concentrations of Cd and As in the mosquito coils. It is important to note that the concentrations of heavy metals such as Cr, Cd, Cu, and Pb reported in the present study and in the Phal (2011) study are much lower compared to those obtained in an earlier study by Liu et al. (1987), which implies that there have been improvements in reducing heavy metal concentrations in mosquito coils.

Mitigating arboviral infections and acute infectious disease is a high priority in Suriname and other South American countries and using mosquito coils to repel and kill vectors is critical. However, their improper use by consumers though may lead to other health problems that should not be ignored.

In the present study, the elemental and organic chemical composition of 10 mosquito coils randomly sampled from imported boxes in Suriname was determined. Only allethrin was detected amongst the target organic chemicals (allethrin, permethrin, and butylated hydroxytoluene). Elemental analyses revealed that Cr, Ni, Se, Co, As, Cd, and Pb were all detected above the method detection limit. The high levels of Cr warrant further research since the burning of Cr at high temperature is known to result in the formation of Cr(VI), a known human carcinogen (Verbinnen et al. 2013). However, the rate of conversion of Cr(III) to Cr(VI) at the temperatures at which the mosquito coils burn may be minimal, and it is unknown how the mosquito coil matrix affects the oxidation of Cr(III) to Cr(VI). This study was limited to analyzing the elemental and organic chemical composition of the mosquito coils. The organic and elemental composition of the ash resulting from the burning of mosquito coils needs to be investigated in order to determine what chemicals are found in this matrix. Indoor burning of mosquito coils may lead to a large build-up of ash particulates and chemicals.

Allethrin, the only target organic compound found in the mosquito coils used in this study degrades rapidly in the environment (US EPA 1988), and therefore does not persist to cause environmental concerns. However, allethrin is highly toxic to fish. Thus, homes with indoor aquaria may also be adversely affected from this pesticide.

References

Anderson RL (1982) Toxicity of fenvalerate and permethrin to several nontarget aquatic invertebrates. Environ Entomol 11:1251–1257

Chang J-Y, Lin J-M (1998) Aliphatic aldehydes and allethrin in mosquito-coil smoke. Chemosphere 36(3):617–624

Cox RL, Wilson WT (1984) Effects of permethrin on the behavior of individually tagged honey bees, Apis mellifera L. (Hymenoptera: Apidae). Environ Entomol 13:375–378

DeMicco A, Cooper KR, Richardson JR, White LA (2010) Developmental neurotoxicity of pyrethroid insecticides in zebrafish embryos. Toxicol Sci 113:177–186

Desneux N, Decourtye A, Delpuech JM (2007) The sublethal effects of pesticides on beneficial arthropods. Annu Rev Entomol 52:81–106

Dubey J, Banerjee A, Meena RK, Kumari KM, Lakhani A (2014) Characterization of polycyclic aromatic hydrocarbons in emissions of different mosquito coils. Bull Environ Contam Toxicol 92(6):650–654

Floyd EY, Geist JP, Werner I (2008) Acute, sublethal exposure to a pyrethroid insecticide alters behavior, growth, and predation risk in larvae of the fathead minnow (Pimephales promelas). Environ Toxicol Chem 27:1780–1787

Kim Y, Jung J, Oh, S, Choi K (2008) Aquatic toxicity of cartap and cypermethrin to different life stages of Daphnia magna and Oryzias latipes. J Environ Sci Health 43(1):56–64

Lawrance CE, Croft AM (2004) Do mosquito coils prevent malaria? A systematic review of trials. J Travel Med 11:92–96

Lee SC, Wang B (2006) Characteristics of emissions of air pollutants from mosquito coils and candles burning in a large environmental chamber. Atmos Environ 40(12):2128–2138

Lin T-S, Shen F-M (2005) Trace metals in mosquito coil smoke. Bull Environ Contam Toxicol 74(1):184–189

Liu WK, Wong MH, Mui YL (1987) Toxic effects of mosquito coil (a mosquito repellent) smoke on rats. I. Properties of the mosquito coil and its smoke. Toxicol Lett 39(2–3):223–230

Liu W, Zhang J, Hashim JH, Jalaludin J, Hashim Z, Goldstein BD (2003) Mosquito coil emissions and health implications. Environ Health Perspect 111(12):1454–1460

McDaniel W (1991) Sample separation procedure for spectrochemical determination of total recoverable elements in biological tissue, Edited by Environmental monitoring system laboratory, US EPA, Cincinnati, OH, 23–27

Morolli C, Quaglio F, Della Rocca G, Malvisi J, Di Salvo A (2006) Evaluation of the toxicity of synthetic pyrethroids to red swamp crayfish (Procambarus clarkii, Girard 1852) and Common Carp (Cyprinus carpio, L. 1758). Bull Fr Pêche Piscic 380–381, 1381–1394

Ogoma SB, Moore, SJ, Maia MF (2012) A systematic review of mosquito coils and passive emanators: defining recommendations for spatial repellency testing methodologies. Parasit vectors 5:1–10

Palmquist K, Salatas J, Fairbrother A (2012) Pyrethroid Insecticides: Use, environmental fate, and ecotoxicology. In: Dr. Farzana Perveen (ed) Insecticides - advances in integrated pest management, ISBN: 978-953-307-780-2, InTech

Phal DA (2011) A comparative study of elemental analysis in mosquito repellent coil and cigarette smoke. Int J Pharm Biol Sci 1(4):462–467

Rice PJ, Drewes CD, Klubertanz TM, Bradbury SP, Coats JR (1997) Acute toxicity and behavioral effects of chlorpyrifos, permethrin, phenol, strychnine, and 2,4-dinitrophenol to 30-day-old Japanese medaka (Oryzias latipes). Environ Toxicol Chem 16:696–704

Roy AA, Baxla SP, Gupta T, Bandyopadhyaya R, Tripathi SN (2009) Particles emitted from indoor combustion sources: size distribution measurement and chemical analysis. Inhalation Toxicol 21(10):837–848

Samsoe-Petersen L, Gustavson K, Madsen T, Mogensen BB, Lassen P, Skjernov K, Christoffersen K, Jorgensen E (2001) Fate and effects of esfenvalerate in agricultural ponds. Environ Toxicol Chem 20:1570–1578

Shu-Chen C, Ruey-Hong W, Li-Jie S, Ming-Chih C, Huei L (2008) Exposure to mosquito coil smoke may be a risk factor for lung cancer in taiwan. J Epidemiol 18(1):19–25

Singh P, Kaur M, John S (2012) Assessment of human health effects associated with exposure to indoor air pollution. Int J Appl Eng Res 7(11):1–5

US EPA (1988) Pesticide fact sheet number 158: allethrin stereoisomers. US EPA, Office of Pesticide Programs, Registration Div, Washington, DC

US EPA (1998) Method 6020 A (SW-846) Inductively coupled plasma-mass spectrometry, Revision 1

Verbinnen B, Billen P, Coninckxloo MV, Vandecasteele C (2013) Heating temperature dependence of Cr(III) oxidation in the presence of alkali and alkaline earth salts and subsequent Cr(VI) leaching behavior. Environ Sci Technol 47:5858–5863

Yan H, Qiao F, Tian M, Row KH (2010) Simultaneous determination of nine pyrethroids in indoor insecticide products by capillary gas chromatography. J Pharm Biomed Anal 51:774–777

Yang TT, Lin ST, Lin TS, Hong WL (2012) Characterization of polycyclic aromatic hydrocarbon emissions in the particulate phase from burning incenses with various atomic hydrogen/carbon ratios. Sci Total Environ 414:335–342

Yang T-T, Lin S-T, Lin T-S, Chung H-Y (2015) Characterization of polycyclic aromatic hydrocarbon emissions in the particulate and gas phase from smoldering mosquito coils containing various atomic hydrogen/carbon ratios. Science of The Total. Environment 506–507:391–400

Zhang L, Jiang Z, Tong J, Wang Z, Han Z, Zhang J (2010) Using charcoal as base material reduces mosquito coil emissions of toxins. Indoor Air 20(2):176–184

Acknowledgments

Research reported in this publication was supported in part by the Fogarty International Center of the National Institutes of Health under Award Numbers R24TW009570 and R24TW009561. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasumba, J., Hettick, B., French, A. et al. Analysis of Pesticides and Toxic Heavy Metals Contained in Mosquito Coils. Bull Environ Contam Toxicol 97, 614–618 (2016). https://doi.org/10.1007/s00128-016-1938-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-016-1938-9