Abstract

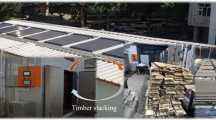

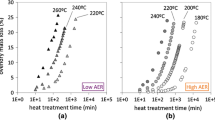

The special interest in Europe for the properties and the use of poplar and its hybrids, especially for the wood technological properties and their effect on the industrial processing of poplar wood, as well as the growing need for fast drying processes producing wood with a low final moisture content, led to this study. It was to be investigated whether high temperature drying (HTD) could also be applied to light hardwoods with properties similar to that of softwoods, like e.g. poplar. Poplar has some peculiar properties, e.g. large heterogenity, wet pocket formation, tension wood, juvenile wood., ..., complicating the application of HTD and increasing the risk for drying defects. Eleven different high temperature drying schedules and one low temperature drying schedule were performed in an experimental electrical drying oven on piles of small sizes of fresh poplar. For reference, five piles of fresh poplar were subjected to accelerated air-drying. Equations were obtained from two seperate multivariate regression analyses with wood characteristics for the first and typical drying-schedule parameters for the second regression, as independent variables, and a number of quantified drying defects as dependent variables for both regressions.

Zusammenfassung

Veranlaßt waren diese Untersuchungen einerseits durch das spezielle Interesse in Europa für die technologische Verwendung von Pappelholz, andererseits durch den wachsenden Bedarf an schnellen Trocknungsprozessen. Zu untersuchen war, inwieweit die Hochtemperaturtrocknung (HTD) auch auf leichte Laubhölzer, am Beispiel der Pappel, anwendbar ist. Pappelholz weist einige spezielle Eigenschaften auf (starke Heterogenität in Dichte und Feuchte, Zugholz, juveniles Holz etc.), welche die Anwendung der HTD schwierig machen. Elf unterschiedliche Hochtemperaturprogramme und eines bei niedriger Temperatur wurden in einem elektrisch beheizten Umlufttrockner mit frischgesägtem Pappelholz von kleiner Abmessung geprüft. Zum Vergleich wurden fünf Stapel frischen Pappelholzes einer beschleunigten Lufttrocknung unterzogen. Durch multivariate Analyse ergaben sich Regressionsgleichungen, wobei einmal die Holzeigenschaften zum andern die Trocknungsparameter als Variablen enthalten sind. Zusätzlich wurden Regressionsgleichungen für Trocknungsfehler abhängig von beiden Variablentypen ermittelt.

Similar content being viewed by others

References

Aleon D (s.d) Le Séchage du Peuplier. Department Bois et Sciage-Section Séchage-CTBA; 10, Avenue de St. Mandé-F-75012 Paris.

Aleon D, Negrie G, Perez J, Snieg O (1988a) Séchage artificiel des sciages. Suivis de cycles de séchage. CTBA Paris. Départment Bois et Sciages. 61 pp.

Aleon D, Negrie G, Perez J, Snieg O (1988b) Séchage de Sapin, Epicea et de Pin Sylvestre à haute température. CTBA Paris. Département Bois et Sciages. 107 pp.

Aleon D, Negrie G, Perez J, Snieg O (1989) Le séchage du Peuplier. CTBA. Département Bois et Sciages. 32 pp.

Aleon D, Dumontieux R, Negrie G, Perez J, Snieg O (1990) Séchage du bois. Guide pratique. CTBA Paris. 103 pp.

Boone SR (1979a) An introduction to high-temperature drying: Past research efforts and definition of terms and procedures. (Reprinted from proceedings of a symposium held at New Albany, Indiana, March 22, 1979, on high-temperature drying of hardwoods). 9 pp.

Boone SR (1979b) An introduction to high-temperature drying: a progress report on current research at FPL. (reprinted from proceedings of a symposium held at New Albany, Indiana, March 22, 1979, on high-temperature drying of hardwoods), 25–40.

Bramhall G, Wellwood RW (1976) Kiln drying of Western Canadian Lumber (Information Report VP-X-159). 112 pp.

Chafe SC (1986) Collapse, volumetric shrinkage, specific gravity and extractives inEucalyptus and other species. Part 1: The shrinkage/specific gravity ratio. Wood Sci. and Technol. 20: 293–307.

Chanrion P, Davesne A (1991) Le séchage des feuillus. Une nécessité économique. CTBA. 203 pp.

Hillis WE (1984) High temperature and chemical effects on wood stability. Part 1: General considerations. Wood Sci. and Technol. 18: 281–293.

Hillis WE, Rozsa AN (1985b) High temperature and chemical effects on wood stability. Part 3: The effect of heat on the rigidity and the stability of Radiata Pine. Wood Sci. and Technol. 19: 93–102.

Hillis WE, Rozsa AN (1985a) High temperature and chemical effects on wood stability. Part 2: The effect of heat on the softening of Radiata Pine. Wood Sci. and Technol. 19: 57–66.

Layton TF, Smith WR, Maeglin RR (1986) An evaluation of the Saw, Dry and Rip Process to convert Red Alder into studs. Wood Sci and Tech 20: 185–200.

MacKay JFG (1975) Properties of Northern Aspen discolored wood related to drying-problems. Wood and Fiber 6 (4): 319–326.

Maeglin RR, Liu JY, Boone RS (1985) High-temperature drying and equalizing: effects on stress relief in Yellow-Poplar lumber. Wood and Fiber Sci 17 (2): 240–253.

Milota RM, Tachernitz JL (1990) Correlation of Leblolly Pine drying at high temperature. Wood and Fiber Sci 22 (3): 298–313.

Morlier P, Guitard D, Thibaut B (1991) Contraintes internes de séchage: apport de la rhéologie du bois, dans le plan transverse. In: 5ième Séminaire International EDG: Des procédés performants de séchage du bois pour accroître la rentabilité et améliorer la qualité des produits. CTBA/Paris, EDG.

Pagnozzi, E (1991) Physique du séchage sous vide. In: 5ième Séminaire International EDG: Des procédés performants de séchage du bois pour accroître la rentabilité et améliorer la qualité des produits. CTBA/Paris, EDG.

Schneider MH, Zhou L (1989) Characterization of wetwood from four Balsam Fir trees. Wood and Fiber Science 21 (1): 1–16.

Sehlstedt-Persson SMB (1995) High-temperature drying of Scots pine. A comparison between HT- and LT-drying. Holz Roh-Werkst 53: 95–99.

Simpson WT (1984) Maintaining lumber quality in press drying by manipulating sawing patterns. Wood and Fiber Sci 16 (3): 411–426.

Taylor FW, Mitchell PH (1987) Drying Pine lumber at very high temperatures and air velocities. Wood and Fiber Sci 19 (3): 239–245.

Vermaas HF, Bariska M (1995) Collapse During low temperature drying ofEucalyptus grandis W. Hill andPinus silvestris L.. Holzforsch u Holzverw 2: 35–40.

Ward JC (1983) Influence of wetwood on pulsed-current resistances in lumber before and during kiln-drying. Wood and Fiber Sci 16 (4): 598–617.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vansteenkiste, D., Stevens, M. & Van Acker, J. High temperature drying of fresh sawn poplar wood in an experimental convective dryer. Holz als Roh- und Werkstoff 55, 307–314 (1997). https://doi.org/10.1007/s001070050235

Issue Date:

DOI: https://doi.org/10.1007/s001070050235