Abstract

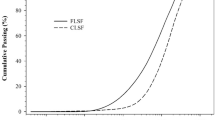

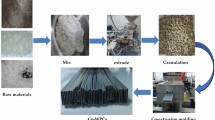

The hydrophilic nature of wood-plastic composites (WPCs) is a disadvantage that impacts its performance in applications for construction and building products. Therefore, developing the WPCs into composites that reduce water absorption needs further evaluation. The current work investigates the effects of different water types (distilled water, and water from the Gulf of Thailand and the Andaman Sea), latex sludge types, and immersion time on the physical and mechanical properties of rubberwood-latex sludge flour-reinforced polypropylene composites. The composite samples were produced by a twin-screw extruder (mixing) and a compression molding machine (forming). The results revealed that the composites exposed to different water conditions for a long period resulted in significant (α = 0.05) reduction in the modulus of rupture, modulus of elasticity, screw withdraw strength, and hardness with maximum percentage reduction values of 79.9, 117.5, 69.9, and 5.84, respectively. However, adding the latex sludge at 25 wt% resisted deterioration. The composites immersed in Andaman Sea water exhibited the least water absorption and deterioration for all the mechanical properties with a minimum hardness loss (3.74%). The composites immersed in distilled water showed the maximum deterioration for all mechanical properties, with 117.5% loss in modulus of elasticity. Overall, adding the latex sludge flour to the composites made them resistant to mechanical properties deterioration, which is favorable for WPCs used in environments involving contact with the seawater, especially the Andaman Sea.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Adhikary KB, Pang S, Staiger MP (2008) Long-term moisture absorption and thickness swelling behaviour of recycled thermoplastics reinforced with Pinus radiate sawdust. Chem Eng J 142(2):190–198. https://doi.org/10.1016/j.cej.2007.11.024

Akil HM, Cheng LW, Ishak M, Bakar AA, Rahman MAA (2009) Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos Sci Technol 69:1942–1948. https://doi.org/10.1016/j.compscitech.2009.04.014

Akil HM, Santulli C, Sarasini F, Tirillo J, Valente T (2014) Environmental effects on the mechanical behavior of pultruded jute/glass fibre-reinforced polyester hybrid composites. Compos Sci Technol 94:62–70. https://doi.org/10.1016/j.compscitech.2014.01.017

Alamri H, Low IM (2013) Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fibre reinforced epoxy hybrid nanocomposites. Compos Part A 44:23–31. https://doi.org/10.1016/j.compositesa.2012.08.026

Alomayri T, Assaedi H, Shaikh FUA, Low IM (2014) Effect of water absorption on the mechanical properties of cotton fabric-reinforced geopolymer composites. J Asian Ceram Soc 2(3):223–230. https://doi.org/10.1016/j.jascer.2014.05.005

Candelier K, Atli A, Alteyrac J (2019) Termite and decay resistance of bioplast-spruce green wood-plastic composites. Eur J Wood Prod 77:157–169. https://doi.org/10.1007/s00107-018-1368-y

Chow CPL, Xing XS, Li RKY (2007) Moisture absorption studies of sisal fibre reinforced polypropylene composites. Compos Sci Technol 67:306–313. https://doi.org/10.1016/j.compscitech.2006.08.005

Daly HB, Brahim HB, Hfaied N, Harchay M, Boukhili R (2007) Investigation of water absorption in pultruded composites containing fillers and low profile additives. Polym Compos 28:355–364. https://doi.org/10.1002/pc.20243

Davies P, Arhant M, Grossmann E (2022) Seawater ageing of infused flax fibre reinforced acrylic composites. Compos Part A Appl Sci Manuf 8:100246. https://doi.org/10.1016/j.jcomc.2022.100246

Elamin MAM, Li SX, Osman AZ, Otitoju TA (2020) Preparation and characterization of wood-plastic composite by utilizing a hybrid compatibilizer system. Ind Crops Prod 154:112659. https://doi.org/10.1016/j.indcrop.2020.112659

Guo G, Finkenstadt VL, Nimmagadda Y (2019) Mechanical properties and water absorption behavior of injection-molded wood fiber/carbon fiber high-density polyethylene hybrid composites. Adv Compos 2:690–700. https://doi.org/10.1007/s42114-019-00116-5

Haftkhani AR, Ebrahimi G, Tajvidi M, Layeghi M (2011) Investigation on withdrawal resistance of various screws in face and edge of wood-plastic composite panel. Mater Des 32:4100–4106. https://doi.org/10.1016/j.matdes.2011.02.065

Homkhiew C, Ratanawilai T, Thongruang W (2016) Long-term water absorption and dimensional stability of composites from recycled polypropylene and rubberwood flour. J Thermoplas Compos Mater 29(1):74–91. https://doi.org/10.1177/0892705713518789

Homkhiew C, Boonchouytan W, Cheewawuttipong W, Ratanawilai T (2018a) Potential utilization of rubberwood flour and sludge waste from natural rubber manufacturing process as reinforcement in plastic composites. J Mater Cycles Waste Manag 20:1792–1804. https://doi.org/10.1007/s10163-018-0749-y

Homkhiew C, Rawangwong S, Boonchouytan W, Thongruang W, Ratanawilai T (2018b) Composites from thermoplastic natural rubber reinforced rubberwood sawdust: Effects of sawdust size and content on thermal, physical, and mechanical properties. Int J Polym Sci 3:1–11. https://doi.org/10.1155/2018/7179527

Homkhiew C, Srivabut C, Rawangwong S, Boonchouytan W (2022) Performance of wood-plastic composites manufactured from post-consumer plastics and wood waste under coastal weathering in Thailand. Fibers Polym 23(9):2679–2693. https://doi.org/10.1007/s12221-022-0014-9

Homkhiew C, Srivabut C, Ratanawilai T, Rawangwong S, Chantaramanee S (2023) Characterization of polypropylene composites using sludge waste from the natural rubber latex industry as reinforcing filler. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-023-01621-y

Jose-Trujillo E, Rubio-Gonzalez C, Rodriguez-Gonzalez JA (2018) Seawater ageing effect on the mechanical properties of composites with different fiber and matrix types. J Compos Mater. https://doi.org/10.1177/0021998318811514

Khamtree S, Ratanawilai T, Ratanawilai S (2020) Determining the optimum conditions for silane treated rubberwood flour-recycled polypropylene composites using response surface methodology. Mater Today Commun 24:100971. https://doi.org/10.1016/j.mtcomm.2020.100971

Law TT, Ishak ZAM (2011) Water absorption and dimensional stability of short kenaf fiber-filled polypropylene composites treated with maleated polypropylene. J Appl Polym Sci 120(1):563–572. https://doi.org/10.1002/app.33184

Mourad AI, Idrisi AH, Wrage MC, Abdel-Magid BM (2019) Long-term durability of thermoset composites in seawater environment. Compos B Eng 168:243–253. https://doi.org/10.1016/j.compositesb.2018.12.076

Mungamurugu PK, Marru P, Sardar HH, Neogi S (2017) Long term performance study of glass reinforced composites with different resins under marin environment. Fibers Polym 18(1):122–130. https://doi.org/10.1007/s12221-017-6543-y

Nosbi N, Akil HM, Ishak ZAM, Bakar AA (2010) Degradation of compressive properties of pultruded kenaf fiber reinforced composite after immersion on various solutions. Mater Des 30:4960–4964. https://doi.org/10.1016/j.matdes.2010.04.037

Industry Outlook 2021–2023: Natural rubber processing, https://www.krungsri.com/, (Accessed: February 2022)

Percin O, Uzun O (2022) Screw withdrawal strength of heat-treated and laminated veneer lumber reinforced with carbon and glass fibers. BioResources 17(2):2486–2500. https://doi.org/10.15376/biores.17.2.2486-2500

Petchpradab P, Yoshida T, Charinpanitkul T, Matsumura Y (2009) Hydrothermal pretreatment of rubber wood for the saccharification process. Ind Eng Chem Res 48(9):4587–4591. https://doi.org/10.1021/ie801314h

Phakee R, Boochathum P (2015) Properties of thermoplastic elastomer composites prepared from Para rubber wood sawdust filled-polypropylene/natural rubber blends. Key Eng Mater 659:490–494. https://doi.org/10.4028/www.scientific.net/KEM.659.490

Phiri JM, Phiri MM, Mpitso K, Hlangothi PS (2020) Curing, thermal and mechanical properties of waste type derived reclaimed rubber-wood flour composites. Mater Today Commun. https://doi.org/10.1016/j.mtcomm.2020.101204

Prabhu R, Mendonca S, D’Souza R, Bhat T (2022) Effect of water absorption on the mechanical properties of alkaline treated bamboo and flax fiber reinforced epoxy composites. Trends Sci 19(18): 5779. https://doi.org/10.48048/tis.2022.5779

Ramli RA, Zakaria NZ, Rahman UUA, Bakhtiar NBA, Mustapha SNH, Lian YM (2018) Effect of mineral fillers on mechanical, thermal and morphological properties of kenaf recycled polyethylene wood plastic composite. Eur J Wood Prod 76:1737–1743. https://doi.org/10.1007/s00107-018-1356-2

Saeb MR, Moghri M (2014) Application of response surface methodology in describing fusion characteristics of rigid poly(vinyl chloride)/nanoclay/wood flour/calcium carbonate hybrid nanocomposites. J Vinyl Addit Technol 34:183–190. https://doi.org/10.1002/vnl.21387

Saetun V, Chiachun C, Riyajan S, Kaewtatip K (2015) Green composites based on thermoplastic starch and rubber wood sawdust. Polym Compos 38:1–7. https://doi.org/10.1002/pc.23669

Saha A, Kumar S, Zindani D (2021) Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym Compos. https://doi.org/10.1002/pc.26164

Sahu P, Gupta MK (2020) Water absorption behavior of cellulosic fibres polymer composites: A review on its effects and remedies. J Ind Text 51:7480–7512. https://doi.org/10.1177/1528083720974424

Samyn P, Driessen F, Stanssens D (2020) Natural rubber composites for paper coating applications. Mater Proc 2:29–37. https://doi.org/10.3390/CIWC2020-06832

Siriwong C, Sridang P, Danteravanich S (2009) Utilization of centrifuged residue from concentrated latex factories and ash from smoked rubber sheet factories as a binder in solidification of decorated materials. Research Report, The Thailand Research Fund (TRF)

Srivabut C, Homkhiew C, Rawangwong S, Boonchouytan W (2022) Possibility of using municipal solid waste for manufacturing wood-plastic composites: effects of natural weathering, wood waste types, and contents. J Mater Cycles Waste Manag 24(4):1407–1422. https://doi.org/10.1007/s10163-022-01443-4

Tian F, Xu X (2022) Dynamical mechanical behaviors of rubber-filled wood fiber composites with urea formaldehyde resin. J Bioresour Bioprod. https://doi.org/10.1016/j.jobab.2022.05.004

Vichaphund S, Intiya W, Kongkaew A, Loykulnant S, Thavorniti P (2012) Utilization of sludge waste from natural rubber manufacturing process as a raw material for clay-ceramic production. Environ Technol 33:2507–2510. https://doi.org/10.1080/09593330.2012.668941

Wu Z, Wang J, Yuan X, Guo X, Zhu Z, Zhang F, Cao P (2022) Research on the orthogonal cutting performance of polyethylene-based wood-plastic composite based on principal component analysis. Eur J Wood Prod. https://doi.org/10.1007/s00107-022-01886-4

Xu M, Li J (2012) Effect of adding rubber powder to poplar particles on composite properties. Bioresour Technol 118:56–60. https://doi.org/10.1016/j.biortech.2012.02.041

Zamri MH, Akil HM, Bakar AA, Ishak ZAM, Cheng LW (2011) Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J Compos Mater. https://doi.org/10.1177/002199831141048

Zhao J, Wang XM, Chang JM, Yao Y, Cui Q (2010) Sound insulation property of wood-waste tire rubber composite. Compos Sci Technol 70:2033–2038. https://doi.org/10.1016/j.compscitech.2010.03.015

Zhou Y, Wang Y, Fan M (2019) Incorporation of tyre rubber into wood plastic composites to develop novel multifunctional composites: Interface and bonding mechanisms. Ind Crops Prod 141:111788. https://doi.org/10.1016/j.indcrop.2019.111788

Acknowledgements

The authors gratefully acknowledge the financial support from the Thailand Science Research and Innovation (Research Grant Code: 65A171000006) and the Rajamangala University of Technology Srivijaya (RMUTSV), Thailand. We would also like to thank Mr. Nonthapat Phakdee and Mr. Pattarapong Phetsimuen for supporting this work.

Author information

Authors and Affiliations

Contributions

S. Khamtree and C. Srivabut wrote the main manuscript, which S. Khamtree wrote in part of Results and Discussion, and C. Srivabut wrote in part of methodology. C. Homkhiew prepared raw materials, designed of experiment, analyzed the results of experiment, wrote in part of Abstract and Conclusions. T. Ratanawilai prepared all of the Figures (Figures 1-10) and final proofreading for manuscript. S. Rawangwong prepared all of the Tables (Tables 1-5) and tested the mechaical and physical properties. All of the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khamtree, S., Srivabut, C., Homkhiew, C. et al. The mechanical properties deterioration of rubberwood-latex sludge flour reinforced polypropylene composites after immersing in different water conditions. Eur. J. Wood Prod. 81, 1223–1237 (2023). https://doi.org/10.1007/s00107-023-01950-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-023-01950-7