Abstract

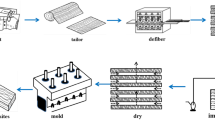

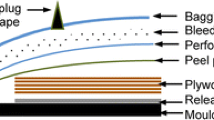

In this research, the feasibility of producing flexible plywood employing combinations of poplar (Populus deltoides) and Paulownia (Paulownia fortunei) veneers with thickness of 1 and 2 mm was investigated. For this aim, layer combinations, treatment type, and the resin type were chosen as variables. Laboratory panels were produced based on Taguchi design of experiments (L18;6^1 3^2) and some physical and mechanical properties of the specimens including density, moisture content, water absorption and thickness swelling after 24 h of immersion in water, modulus of rupture and modulus of elasticity parallel and perpendicular to the grain, bonding quality, and bending radius were determined. The present work focuses on using Taguchi method in order to detect the optimum combination of the parameters. The results revealed that bending radius was considerably influenced by the properties of wood and the thickness of the core veneer. The outcomes showed that as the thickness of the core veneer decreased, the bending radius increased. Accordingly, the optimum choice for the core layer of plywood is poplar with a thickness of 1 mm, and the best elastic attributes were obtained for plywood with veneers treated by the Pro-Glu solution. Polyvinyl acetate also demonstrated an increase in flexibility, and a decrease in MOE. The experimental samples of the manufactured plywood could ultimately bend around a cylinder with a diameter of 6.5 mm to reach the minimum bending radius with no sign of damage.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article. Raw data are also available from the corresponding authors, upon reasonable request.

Code Availability

Not applicable.

References

Adhikari BB, Appadu P, Kislitsin V, Chae M, Choi P, Bressler DC (2016) Enhancing the adhesive strength of a plywood adhesive developed from hydrolyzed specified risk materials. Polymers 8(8):285. https://doi.org/10.3390/polym8080285

Al-Kubaisi O, Mohotti D, Al-Qassag O (2020) Prediction of plywood deformation under the impact of windborne debris using Taguchi method. In IOP Conference Series: Materials Science and Engineering (Vol. 671, No. 1, p. 012096). IOP Publishing. https://doi.org/10.1088/1757-899X/671/1/012096

Aydın İ, Çolak S, Çolakoğlu G, Salih E (2004) A comparative study on some physical and mechanical properties of laminated veneer lumber (LVL) produced from Beech (Fagus orientalis Lipsky) and Eucalyptus (Eucalyptus camaldulensis Dehn.) veneers. Holz Roh- Werkst 62(3):218–220. https://doi.org/10.1007/s00107-004-0464-3

Baishya P, Maji TK (2014) Studies on effects of different cross-linkers on the properties of starch-based wood composites. ACS Sustain Chem Eng 2(7):1760–1768. https://doi.org/10.1021/sc5002325

Barboutis I, Kamperidou V (2011) Properties of two different thicknesses 3-ply plywood of tree-of-heaven veneers. Properties of two different thicknesses 3-ply plywood of tree-of-heaven veneers.,9–16. https://www.researchgate.net/publication/293122317

Bekhta P, Sedliačik J (2019) Environmentally-friendly high-density polyethylene-bonded plywood panels. Polymers 11(7):1166. https://doi.org/10.3390/polym11071166

Biadała T, Czarnecki R, Dukarska D (2015) Attempt to produce flexible plywood with use of Europe wood species. Wood Res 60(2):317–328

Biadała T, Czarnecki R, Dukarska D (2020) Water resistant plywood of increased elasticity produced from European wood species. Wood Res 65:111–124

Bijaisoradat O, Luttapreecha M, Manuspiya H (2020) Eco composites with synergistic combinations of natural rubber latex and wood flour toughened recycled HDPE. Mater Today Commun 25:101483. https://doi.org/10.1016/j.mtcomm.2020.101483

Borysiuk P, Zado A, Sosinska K, Gowin L, Mrozik M, Nowakowski M (2003) Flexible plywood made of Polish timber.Annals of Warsaw Agricultural University. Forestry and Wood Technology, 53

Borysiuk P, Dziurka D, Jablonski M, Sosinska K (2007) Selected properties of flexible plywood made of domestic wood species.Annals of Warsaw University of Life Sciences-SGGW. Forestry and Wood Technology, 61

Gáborík J, Gaff M, Ruman D, Záborský V, Kašíčková V, Sikora A (2016) Adhesive as a factor affecting the properties of laminated wood. BioResources 11(4):10565–10574

Hamzaçebi C (2016) Optimization of process parameters in oriented strand board manufacturing by Taguchi method. BioResources 11(3):5987–5993

Kamala BS, Kumar P, Rao RV, Sharma SN (1999) Performance test of laminated veneer lumber (LVL) from rubber wood for different physical and mechanical properties. Holz Roh- Werkst 57(2):114–116. https://doi.org/10.1007/s001070050025

Kawalerczyk J, Dziurka D, Mirski R, Trociński A (2019) Flour fillers with urea-formaldehyde resin in plywood. BioResources 14(3):6727–6735

Mendes RF, Mendes LM, Júnior JBG, dos Santos RC, Bufalino L (2009) The adhesive effect on the properties of particleboards made from sugar cane bagasse generated in the distiller. Revista de Ciências Agrárias 32(2):209–218. https://doi.org/10.19084/rca.15739

Pirayesh H, Moradpour P, Sepahvand S (2015) Particleboard from wood particles and sycamore leaves: Physico-mechanical properties. Eng Agric Environ food 8(1):38–43. https://doi.org/10.1016/j.eaef.2014.07.003

Pundir R, Chary GHVC, Dastidar MG (2018) Application of Taguchi method for optimizing the process parameters for the removal of copper and nickel by growing Aspergillus sp. Water Resour Ind 20:83–92. https://doi.org/10.1016/j.wri.2016.05.001

Souza AM, Nascimento MF, Almeida DH, Silva DAL, Almeida TH, Christoforo AL, Lahr FA (2018) Wood-based composite made of wood waste and epoxy-based ink-waste as adhesive: A cleaner production alternative. J Clean Prod 193:549–562. https://doi.org/10.1016/j.jclepro.2018.05.087

Taguchi G, Chowdhury S, Wu Y (2005) Taguchi’s quality engineering handbook. Wiley

Tiryaki S, Hamzaçebi C, Malkoçoğlu A (2015) Evaluation of process parameters for lower surface roughness in wood machining by using Taguchi design methodology. Eur J Wood Prod 73(4):537–545. https://doi.org/10.1007/s00107-015-0917-x

Xie Z, Chen Y, Wang C, Liu Y, Chu F, Jin L (2014) Effects of bio-based plasticizers on mechanical and thermal properties of PVC/wood flour composites. BioResources 9(4):7389–7402

Zhang Y, Chen M, Zhang J, Li J, Shi SQ, Gao Q (2020) A High-Performance Bio‐Adhesive Using Hyperbranched Aminated Soybean Polysaccharide and Bio‐Based Epoxide. Adv Mater Interfaces 7(9):2000148. https://doi.org/10.1002/admi.202000148

Acknowledgements

The authors gratefully acknowledge the support of Iranchoob Company for preparing the layers.

Funding

This study was supported by the Vice Chancellor for Research, Faculty of Natural resources, College of Agriculture and Natural Resources, University of Tehran, I. R. Iran [Grant number 30541/6/11].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sedighizadeh, P., Moradpour, P. & Hosseinabadi, H.Z. Possibility of making flexible three-ply plywood using poplar (Populus deltoides) and Paulownia (Paulownia fortunei) veneers. Eur. J. Wood Prod. 81, 209–221 (2023). https://doi.org/10.1007/s00107-022-01857-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-022-01857-9