Abstract

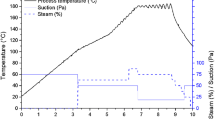

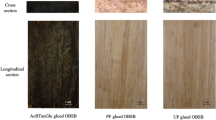

The purpose of this study was to analyze the chemical component change in betung bamboo (Dendrocalamus asper (Schult. & Schult. F.) Backer ex K. Heyne) strands after different steam and washing treatments, and their influence on the physical and mechanical properties of bamboo-oriented strand boards (BOSB). Strands were prepared with three different treatments: (1) steam-only, (2) steam followed by washing with distilled water, and (3) steam followed by washing with 1% sodium hydroxide solution. The steaming process was performed at 126 °C for 1 h at a pressure of 0.14 MPa. Chemical components such as holocellulose, alpha-cellulose, lignin, and starch were analyzed. Phenol formaldehyde resin was used to manufacture BOSB, and the physical and mechanical properties were evaluated in the final products. Steam treatments resulted in changes in chemical components that affected the physical and mechanical properties of BOSB. These changes were mainly caused by the degradation of hemicellulose and extractives dissolved in hot water or 1% sodium hydroxide. These treatments increased the bonding between strands, resulting in higher dimensional stability and strength of BOSB. Considering all the performed experiments, the steam treatment followed by washing with 1% sodium hydroxide was the best treatment for manufacturing BOSB.

Similar content being viewed by others

References

Adrin A, Febrianto F, Sadiyo S (2013) Properties of oriented strand board prepared from steam treated bamboo strands under various adhesive combinations. J Tropical Wood Sci Technol 11(2):109–119

Anokye R, Bakar ES, Ratnansingam J, Awang KB (2016) Bamboo properties and suitability as a replacement for wood. PJSRR 2(1):63–79

Anwar UMK, Paridah MT, Hamdan H, Zaidon A, Hanim AR, Nordahlia AS (2012) Adhesion and bonding properties of low molecular weight phenol-formaldehyde treated plybamboo. J Trop For Sci 24(3):379–386

Asada T, Ishihara S, Yamane T, Toba A, Yamada A, Oikawa K (2002) Science of bamboo charcoal: study on carbonizing temperature of bamboo charcoal and removal capability of harmful gases. J Health Sci 48(6):473–479

Ashaari Z, Salim S, Halis R, Yusof MNM, Sahri MH (2010) Characteristic of pulp produced from refiner mechanical pulping of tropical bamboo (Gigantochloa scortechinii). J Trop Agric Sci 33(2):251–258

ASTM (2013) D1107-96, Standard test method for ethanol-toluene solubility of wood. ASTM International. West Conshohocken, PA, US

Bhuiyan T, Hirai N (2005) Study of crystalline behavior of heat-treated wood cellulose during treatments in water. J Wood Sci 51:42–47

Boonstra M, Tjeerdsma B (2006) Chemical analysis of heat treated softwoods. Holz Roh-Werkst 64:204–211

Browning BL (1967) Methods of wood chemistry, vol I. Wiley, New York

BSN (1992) SNI 01 2891-1992 food and beverages test. National Standardization Institution, Jakarta

BSN (2004) SNI 06-6989.11-2004 pH meter. National Standardization Institution, Jakarta

Cao Y, Zhang Y, Lu J, Huang R (2012) Response mechanisms and prediction models of changes in wood chemical component to steam-heat treatment. In: proceedings of 2012 international conference on biobase material science and energy, changsa, China, pp 292–296

Cheng S, Huang A, Wang S, Zhang Q (2016) Effect of different heat treatment temperature on the chemical composition and structure of Chinese fir wood. BioRes 11(2):4006–4016

Dransfield S, Widjaya EA (1995) Plant resources of South-East Asia No. 7: Bamboos. Yayasan PROSEA, Bogor, Indonesia

Esteves B, Pereira H (2009) Wood modification by heat treatment: a review. BioRes 4(1):370–404

Esteves B, Velez MA, Domingos I, Pereira H (2008) Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 62:344–351

Esteves B, Marquez VA, Domingos I, Pereira H (2013) Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas Ciencia y Tecnol 15(2):245–258

Febrianto F, Manalu LI, Hidayat W, Bakar ES, Kim NH, Kwon JH (2009) Development of oriented strand board from Acacia wood (Acacia mangium Willd): effect of pretreatment of strand and adhesive content on the physical and mechanical properties of OSB. J Korean Wood Sci Technol 37(2):121–127

Febrianto F, Hidayat W, Samosir TP, Lien HC, Song HD (2010) Effect of strand combination on dimensional stability and mechanical properties of oriented strand board made from tropical fast growing species. J Bio Sci 10(3):267–272

Febrianto F, Sahroni Hidayat W, Bakar ES, Kwon GJ, Kwon JH, Kim NH (2012) Properties of oriented strand board made from Betung bamboo (Dendrocalamus asper (Schultes.f) Backer ex Heyne). Wood Sci Technol 46(1–3):53–62

Febrianto F, Purnamasari I, Arinana Gumilang A, Kim NH (2013) Steaming effect on natural durability of bamboo oriented strand board against termites and powder post beetle attacked. J Tropical Wood Sci Technol 11(2):1162–1170

Febrianto F, Jang JH, Lee SH, Santosa IA, Hidayat W, Kwon JH, Kim NH (2015) Effect of bamboo species and resin content on properties of oriented strand board prepared from steam-treated bamboo strands. BioRes 10(2):2642–2655

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, reactions. Walter de Gruyter, New York

Iswanto AH, Febrianto F, Wahyudi I, Hwang WJ, Lee SH, Kwon JH, Kwon SM, Kim NH, Kondo T (2010) Effect of pre-treatment technique on physical, mechanical and durability properties of oriented strand board made from Sentang wood (Melia excelsa Jack). J Fac Agr Kyushu Univ 55(2):371–377

JSA (2003) JIS A 5908: 2003 Particleboards. Japan Standards Association, Tokyo

Kamthai S, Puthson P (2005) The physical properties, fiber morphology and chemical composition of sweet bamboo (Dendrocalamus asper Backer). Kasetsart J Nat Sci 39:581–587

Kucerova V, Lagana R, Vybohova E, Hyrosova T (2016) The effect of chemical change during heat treatment on the color and mechanical properties of fir wood. BioRes 11(4):9079–9094

Luo H, Yue L, Wang N, Zhang H, Lu X (2014) Manufacture of binderless fiberboard made from bamboo processing residue by steam explosion pretreatment. Wood Res 59(5):861–870

Maloney TM (1993) Modern particleboard and dry-process fibreboard manufacturing. Forest Products Society, Madison

Matsushita Y, Kakehi A, Miyawaki S, Yasuda S (2004) Formation and chemical structure of acid-soluble lignin II: reaction of aromatic nuclei model compound with xylan in the presence of a counterpart for condensation, and behavior of lignin model compound with guaiacyl and syringyl nuclei in 72% sulfuric acid. J Wood Sci 50:136–141

Maulana S, Busyra I, Fatrawana A, Hidayat W, Sari RK, Sumardi I, Wistara NJ, Lee SH, Kim NH, Febrianto F (2017) Effects of steam treatment on physical and mechanical properties of bamboo oriented strand board. J Korean Wood Sci and Tech 45(6):872–882

Monshi A, Foroughi MR, Monshi MR (2012) Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J Nano Sci Eng 2(3):154–160

Nawawi DS, Syafii W, Akiyama T, Matsumoto Y (2016) Characteristics of syringyl-guaiacyl lignin in reaction wood in the gymnosperm Gnetum gnemon L. Holzforschung 70(7):593–602

Nawawi DS, Akiyama T, Syafii W, Matsumoto Y (2017a) Characteristics of β-O-4 structures in defferent reaction wood lignins of Eusideroxylon zwageri and four other woody species. Holzforschung 71(1):11–20

Nawawi DS, Syafii W, Tomoda I, Uchida Y, Akiyama T, Yokoyama T, Matsumoto Y (2017b) Characteristics and reactivity of lignin in acacia and eucalyptus wood. J Wood Chem Tech 37(4):273–282

Nugroho N, Bahtiar ET, Lestari DP, Nawawi DS (2013) Variation of tensile strength and cell wall component of four bamboo species. J Ilmu Teknol Kayu Trop 11(2):140–152

Nuopponen M, Vuorinen T, Jamsa S, Viitaniemi P (2003) The effects of heat treatment on behavior of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37(2):109–115

Nuopponen M, Vuorinen T, Jamsa S, Viitaniemi P (2005) Thermal modification in softwood studied by FT-IR and UV resonance Raman spectroscopies. J Wood Chem Tech 24(1):13–26

Rahman KS, Alam DM, Islam N (2012) Some physical and mechanical properties of bamboo mat-wood veneer plywood. J Biological Sci 1(2):61–64

Sakuno T, Moredo CC (1993) Bonding of selected tropical woods-effects of extractives related properties. In: Branham SJ, Chun C (eds) Chung YH. Adhesive Technology and Bonded Tropical Wood Products, Taipei, pp 166–189

Santhoshkumar R, Bhat KV (2014) Various changes of starch content in the culms of selected bamboo species, Bambusa bambos (L.) Voss and Dendrocalamus strictus Ness at different storage methods. J Indian bot Soc 93(1&2):82–86

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sharma B, Gatoo A, Ramage MH (2015) Effect of processing methods on the mechanical properties of engineered bamboo. Construct Build Mater 83:95–101

Structural Board Association (2004) Oriented strand board in wood frame construction. Structural Board Association. Canadian Edition 2004, Edmonton, AB, Canada

TAPPI (1999) T-207 Water solubility of wood and pulp. TAPPI press, Atlanta

TAPPI (2000) UM 250 Acid soluble lignin in wood and pulp. TAPPI press, Atlanta

TAPPI (2002a) T-222 Acid-insoluble lignin in wood and pulp. TAPPI press, Atlanta

TAPPI (2002b) T-212 One percent sodium hydroxide solubility of wood and pulp. TAPPI press, Atlanta

Verma CS, Chariar VM (2012) Development of layered laminated bamboo composite and their mechanical properties. Compos B 43:1063–1069

Wahab R, Mustafa MT, Salam MA, Sudin M, Samsi HW, Rasat MSM (2013) Chemical composition of four cultivated tropical bamboo in genus Gigantochloa. J Agric Sci 5(8):66–75

Wang YN, Ko CH, Lee CY, Tsai HP, Chen WH, Hwang WS, Tsai MJ, Chang FC (2011) Evaluation of bamboo as a feedstock for bioethanols in Taiwan. In: proceeding of world renewable energy congress. Linkoping University Electronic Press, Linkoping pp 171–177

Widjaya EA, Utami NW, Saefudin (2004) Bamboo cultivation guide. LIPI, Bogor

Wikberg H, Maunu S (2004) Characterisation of thermally modified hard- and softwoods by 13C CPMAS NMR. Carbohydr Polym 58:461–466

Yamashiro K, Nishida H (2015) Structural and compositional changes of bamboo fibers during super-heated steam treatment improved mechanical properties of polypropylene/bamboo biocomposite. Internat. J Biomass Renew 4(2):8–16

Yuan Z, Wen Y, Kapu NS, Beatson R, Martinez DM (2017) A biorefinery scheme to fractionate bamboo into high-grade dissolving pulp and ethanol. Biotechnol Biofuels 10:38

Zhang Y, Zhu R, Yu W (2017) Effect of steam treatment on the properties of Phyllostachys iridescens bamboo composite. Cell Chem Technol 51(1–2):103–108

Zhao RJ, Jiang ZH, Hse CY, Shupe TF (2010) Effect of steam treatment on bending properties and chemical composition of moso bamboo (Phyllostachys pubescens). J Trop Forest Sci 22(2):197–201

Acknowledgements

The authors acknowledge the support from the Ministry of Research, Technology, and Higher Education for funding through a “Competitive Research” grant (Grant No: 5618/IT3.11/PN/2017) and Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (No. 2018R1A6A1A03025582).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fatrawana, A., Maulana, S., Nawawi, D.S. et al. Changes in chemical components of steam-treated betung bamboo strands and their effects on the physical and mechanical properties of bamboo-oriented strand boards. Eur. J. Wood Prod. 77, 731–739 (2019). https://doi.org/10.1007/s00107-019-01426-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01426-7