Abstract

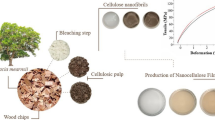

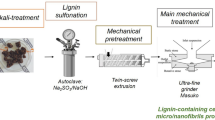

The use of natural resources for the production of nanostructured cellulosic films of high quality could reduce pollution and raw material costs for cellulose industry. This work provides innovative information about the use of Amazonian species not explored in studies involving the production of nanostructured films, as well as the evaluation of important characteristics that may be decisive for the destination of the product. The aim of this study was to modify Schizolobium parahyba var. amazonicum (paricá) waste fibers through alkaline (NaOH) and bleaching (NaClO2) treatments for cellulose nanofibrils (CNFs) production and evaluate the characteristics of the nanofibrils and the surface as well as the mechanical resistance of the films obtained. The alkaline treatment was carried out with sodium hydroxide (5% NaOH solution (w/v); 2 h), while the bleaching was performed using sodium chlorite and glacial acetic acid (1.5 g NaClO2; 10 drops of glacial acetic acid; 1 h). The treatments were performed in sequence, producing nanofibrils after alkaline treatment and after bleaching. Lignin content did not change with the alkaline treatment, but it significantly decreased with bleaching (from 26.1 to 6.8%). Hemicelluloses content decreased with the sequence of treatments. FTIR results showed that the mechanical defibrillation caused disruption of the fiber bonds. The temperature of thermal degradation observed in DTG analysis increased from the natural fibers (243 °C) to alkaline + bleached fibers (255 °C). The defibrillation process led to higher thermal stability of the alkaline + bleached nanofibrils in comparison to fibers. Moreover, films were prepared from the obtained CNFs and evaluated by the mechanical properties and surface contact angle. The mechanical properties showed values of 6.93 ± 0.18 GPa for modulus of elasticity (MOE) for the films produced from material which was submitted to the bleaching treatment. The results highlighted a more hydrophobic surface of the film produced with the CNFs generated from the bleached fibers. The results of mechanical properties showed the superiority of the films produced from the alkaline + bleached fibers.

Similar content being viewed by others

References

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with an uniform width of 15 nm from wood. Biomacromolecules 8:3276–3278

ABNT (2003) NBR 13999: paper, board, pulps and wood—determination of residue (ash) on ignition at 525 °C. ABNT, Brazilian Association of Technical Standards, Rio de Janeiro

ABNT (2010a) NBR 7989: pulp and wood—determination of acid-insoluble lignin. ABNT, Brazilian Association of Technical Standards, Rio de Janeiro

ABNT (2010b) NBR 14853: determination of soluble matter in ethanol-toluene and in dichloromethane and in acetone. ABNT, Brazilian Association of Technical Standards, Rio de Janeiro

Abraham E, Deepa B, Pothan LA, Jacob M, Thomas S, Cvelbar U (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres: a novel approach. Carbohydr Polym 86:1468–1475

Agarwal UP, Zhu JY, Ralph SA (2013) Enzymatic hydrolysis of loblolly pine: effects of cellulose crystallinity and delignification. Holzforschung 67:371–377

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99:1664–1671

Almeida DH, Scaliante RM, Macedo LB, Macêdo AN, Dias AA, Christoforo AL, Junior CC (2013) Structural characterization of the Amazonian wood specie paricá (Schizolobium amazonicum Herb) in members. Rev Árvore 37:1175–1181

ASTM D828-16 (2016) Standard Test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus. In: ASTM, American Society for Testing and Materials, West Conshohocken

Bai L, Hu H, Xu J (2012) Influences of configuration and molecular weight of hemicelluloses on their paper-strengthening effects. Carbohydr Polym 88:1258–1263

Bartz J, Madruga KM, Klein B, Pinto VZ, Dias ARG (2012) Pasting properties of native and acetylated rice starches. Braz J Food Technol 15:78–83

Bertoti AR, Luporini S, Esperidião MCA (2009) Effects of acetylation in vapor phase and mercerization on the properties of sugarcane fibers. Carbohydr Polym 77:20–24

Bonelli CMC, Elzubair A, Suarez JCM, Mano EB (2005) Thermal, mechanical and morphological behavior of recycled high-density polyethylene reinforced with piassava fiber. Polimeros 15:256–260

Bouiri B, Amrani M (2010) Elemental chlorine-free bleaching halfa pulp. J Ind Eng Chem 16:587–592

Browning BL (1963) The chemistry of wood. Interscience, Warrenvile, p 689

Bufalino L, Sena Neto AR, Tonoli GHD et al (2015) How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 22:3657–3672

Burhenne L, Messmer J, Aicher T, Laborie MP (2013) The effect of the biomass components lignin, cellulose and hemicellulose on TGA and fixed bed pyrolysis. J Anal Appl Pyrol 101:177–184

Carvalho PER (2007) Paricá Schizolobium amazonicum. Technical Note 142, Colombo, Paraná. EMBRAPA Florestas, p 8

Chaker A, Sabrine A, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20:2863–2875

Chen C, Baucher M, Christensen JH, Boerjan W (2001) Biotechnology in trees: towards improved paper pulping in lignin engineering. Euphytica 118:185–195

Chirayil CJ, Joy J, Mathew L, Mozetic M, Koetz J, Thomas S (2014) Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind Crop Prod 59:27–34

Correa AC (2010) Preparation of cellulose nanofibers from curaua fibers for the development of polymeric nanocomposites with EVA. Thesis, Federal University of São Carlos

Correia VC, Santos V, Sain M, Santos SF, Leão AL, Savastano Junior H (2016) Grinding process for the production of nanofibrillated cellulose based on unbleached and bleached bamboo organosolv pulp. Cellulose 23:2971–2987

Douglas RS, Hasan J, Hou-min C, John FK (2006) Inorganic reactions in chlorine dioxide bleaching of softwood kraft pulp. J Wood Chem Technol 26:201–213

Eichhorn SJ, Dufresne A, Arangurem M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nagakaito AN, Mangalam A, Simonsem J, Benight AS, Bismarck A, Berglund LA, Peijis T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Featherstone A, Viney D, Mosbye J, Richardson DE (2006) Deposit control: does adsorption of colloidal extractives to bentonite affect the dissolution of resin acids? In: 60th Appita Annual Conference, Melbourne Australia, pp 417–420

Ferrer A, Quintana E, Filpponen I, Solala I, Vidal T, Rodriguez A, Laine J, Rojas OJ (2012) Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19:2179–2193

Fisher T, Hajaligol M, Waymack B, Kellogg D (2002) Pyrolysis behavior and kinetics of biomass derived materials. J Anal Appl Pyrol 62:331–349

Fonseca CS, Silva TF, Silva MF, Oliveira IRC, Mendes RF, Hein PRG, Mendes LM, Tonoli GHD (2016) Eucalyptus cellulose micro/nanofibers in extruded fiber-cement composites. Cerne 22:1–9

Fortunati F, Luzia F, Jiménezb A et al (2016) Revalorization of sunflower stalks as novel sources of cellulose nanofibrils and nanocrystals and their effect on wheat gluten bionanocomposite properties. Carbohydr Polym 149:357–368

Gani A, Naruse I (2007) Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew Energy 32:649–661

Garside P, Wyeth P (2003) Identification of cellulosic fibres by FTIR spectroscopy: thread and single fibre analysis by attenuated total reflectance. Stud Conserv 48:269–275

Gassan J, Bledzki AK (1999) Possibilities for improving the mechanical properties of jute/epoxy composites by alkali treatment of fibres. Compos Sci technol 59:1303–1039

Guimarães Júnior M, Botaro VR, Novack KM, Teixeira FG, Tonoli GHD (2015) Starch/PVA-based nanocomposites reinforced with bamboo nanofibrils. Ind Crop Prod 70:72–83

Hamzeh Y, Ashori A, Khorasani Z, Abdulkhani A, Abyaz A (2013) Pre-extraction of hemicelluloses from bagasse fibers: effects of dry-strength additives on paper properties. Ind Crop Prod 43:365–371

Hassan ML, Mathew AP, Hassan EA, El-Wakil NA, Oksman K (2012) Nanofibers from bagasse and rice straw: Process optimization and properties. Wood Sci Technol 46:193–205

Holmbom B (2000) Resin reactions and deresination in bleaching. In: Back EL, Allen LH (eds) Pitch control, wood resin and deresination. TAPPI Press, Atlanta, pp 231–244

Hornsby PR, Hinrichsen E, Tarverdi K (1997) Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibers. Part II. Analysis of composite microstructure and mechanical properties. J Mater Sci 32:1009–1015

Huang Y-F, Chiueh P-T, Lo S-L (2016) A review on microwave pyrolysis of lignocellulosic biomass. Sustainable Env Res 26:103–109

Hubbell CA, Ragauskas AJ (2010) Effect of acid–chlorite delignification on cellulose degree of polymerization. Bioresour Technol 101:7410–7415

Ichazo MN, Albano C, González J, Pereira R, Candal MV (2001) Polypropylene/wood flour composites: treatments and properties. Compos Struct 54:207–214

Ioelovich M (2008) Cellulose as nanostructured polymer: short review. Bioresource 3:1403–1418

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9:1022–1026

Joseph K, Thomas S, Pavithran C (1996) Effect of chemical treatment on the tensile properties of short sisal fibre-reinforced polyethylene composites. Polymer 37:5139–5149

Kennedy F, Phillips GO, Williams EPA (1987) Wood and cellulosic: industrial utilization, biotechnology, structure and properties. Halsted, New York, p 1130

Khan AS, Man Z, Bustam MA, Nasrullah A, Ullah Z, Sarwono A, Shah FU, Muhammad N (2018) Efficient conversion of lignocellulosic biomass to levulinic acid using acidic ionic liquids. Carbohyd Polym 181:208–214

Kim H, Ahn Y, Kwak S-Y (2016) Comparing the influence of acetate and chloride anions on the structure of ionic liquid pretreated lignocellulosic biomass. Biomass Bioenerg 93:243–253

Lehto J, Alén R (2013) Alkaline pre-treatment of hardwood chips prior to delignification. J Wood Chem Technol 33:77–91

Leiviskä T, Rämö J (2008) Coagulation of wood extractives in chemical pulp bleaching filtrate by cationic polyelectrolytes. J Hazard Mater 153:525–531

Leiviskä T, Rämö J, Nurmesniemic H, Pöykiö R, Kuokkanene T (2009) Size fractionation of wood extractives, lignin and trace elements in pulp and paper mill wastewater before and after biological treatment. Water Res 43:3199–3206

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Env 15:25–33

Liu H, Hu H, Jahan MS, Ni Y (2013) Furfural formation from the pre-hydrolysis liquor of a hardwood kraft-based dissolving pulp production process. Ind Eng Chem Res 52:3974–3979

López-Gonzales D, Fernandez-Lopez M, Valverde JL, Sanchez-Silva L (2013) Thermogravimetric mass spectrometric analysis. Bioresour Technol 143:562–574

Mariano M, Cercená R, Soldi V (2016) Thermal characterization of cellulose nanocrystals isolated from sisal fibers using acid hydrolysis. Ind Crop Prod 94:454–462

Marinelli AL, Monteiro MR, Ambrósio JD, Branciforti MC, Kobayashi M, Nobre AD (2008) Development of polymeric composites with natural fibers: a contribution to the sustainability of Amazon. Polimeros 18:92–99

Mirmehdi S, Hein PRG, Sarantópoulos CIGL, Dias MV, Tonoli GHD (2017) Cellulose nanofibrils/nanoclay hybrid composite as a paper coating: effects of spray time, nanoclay content and corona discharge on barrier and mechanical properties of the coated papers. Food Packag Shelf Life. https://doi.org/10.1016/j.fpsl.2017.11.007

Moradbak A, Tahir PM, Mohamed AZ, Tahir PMD, Abdi MM, Razalli RL, Halis R (2018) Isolation of cellulose nanocrystals from Gigantochloa scortechinii ASAM pulp. Eur J Wood Prod 76(3):1021–1027

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Moubarik A, Grimi N, Boussetta N (2013) Structural and thermal characterization of Moroccan sugar cane bagasse cellulose fibers and their applications as a reinforcing agent in low density polyethylene. Compos Part B Eng 52:233–238

Muranaka Y, Nakagawa H, Hasegawa I, Maki T, Hosokawa J, Ikuta J, Mae K (2017) Lignin-based resin production from lignocellulosic biomass combining acidic saccharification and acetone-water treatment. Chem Eng J 308:754–759

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84:2222–2234

Nakamura T, Kawamoto H, Saka S (2008) Pyrolysis behavior of Japanese cedar wood lignin studied with various model dimers. J Anal Appl Pyrol 81:173–182

Nevárez LAM, Casarrubias LB, Celzard A, Fierro V, Muñoz VT, Davila AC, Lubian JRT, Sánchez GG (2011) Biopolymer-based nanocomposites: effect of lignin acetylation in cellulose triacetate films. Sci Technol Adv Mater 12:1–16

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598

Nygårds S (2011) Nanocellulose in pigment coatings: aspects of barrier properties and printability in offset. In: Dissertation (Master’s in Physics, Chemistry)—Linköpin University, p 42

Oliveira PE, Pesenti H, Cunha AG, Gacitúa W, Petit-Breuilh X (2018) Exploring an oxidative bleaching treatment for Chilean bamboo: a source of cellulose for biofuel generation and the nanotech industry. Eur J Wood Prod 76(3):1009–1019

Orue A, Jauregi A, Unsuain U, Labidi J, Eceiza A, Arbelaiz A (2016) The effect of alkaline and silane treatments on mechanical properties and breakage of sisal fibers and poly (lactic acid)/sisal fiber composites. Compos Part A Appl S 84:186–195

Panthapulakkal S, Sain M (2013) Isolation of nano fibres from hemp and flax and their thermoplastic composites. Plastic Polym Technol 2:9–16

Puangsin B, Fujisawa S, Kuramae R et al (2013) TEMPO-mediated oxidation of hemp bast holocellulose to prepare cellulose nanofibrils dispersed in water. J Polym Environ 21:555–563

Qin M, Hannuksela T, Holmbom B (2003) Physico-chemical characterisation of TMP resin and related model mixtures. Colloids Surf A 221:243–254

Quiévy N, Jacquet N, Sclavons M, Deroanne C, Paquot M, Devaux J (2010) Influence of homogenization and drying on the thermal stability of microfibrillated cellulose. Polym Degrad Stab 95:306–314

Rohaizu R, Wanrosli WD (2017) Sono-assisted TEMPO oxidation of oil palm lignocellulosic biomass for isolation of nanocrystalline cellulose. Ultrason Sonochem 34:631–639

Scatolino MV, Bufalino L, Mendes LM, Guimarães Júnior M, Tonoli GHD (2017a) Impact of nanofibrillation degree of eucalyptus and Amazonian hardwood sawdust on physical properties of cellulose nanofibril films. Wood Sci Technol 51:1095–1115

Scatolino MV, Silva DW, Bufalino L, Tonoli GHD, Mendes LM (2017b) Influence of cellulose viscosity and residual lignin on water absorption of nanofibril films. Procedia Engineer 200:155–161

Sena Neto AR, Araujo MAM, Souza FVD, Mattoso LHC, Marconcini JM (2013) Characterization and comparative evaluation of thermal, structural, chemical, mechanical and morphological properties of six pineapple leaf fiber varieties for use in composites. Ind Crop Prod 43:529–537

Serna LVD, Alzate CEO, Alzate CAC (2016) Supercritical fluids as a green technology for the pretreatment of lignocellulosic biomass. Biores Technol 199:113–120

Sgriccia N, Hawley MC, Misra M (2008) Characterization of natural fiber surfaces and natural fiber composites. Compos Part A 39:1632–1637

Sharma RK, Wooten JB, Baliga VL, Lin X, Chan WG, Hajaligol MR (2004) Characterization of chars from pyrolysis of lignin. Fuel 83:1469–1482

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Subhedar PB, Ray P, Gogate PR (2017) Intensification of delignification and subsequent hydrolysis for the fermentable sugar production from lignocellulosic biomass using ultrasonic irradiation. Ultrason Sonochem 40:140–150

Sun RC, Tomkinson J, Zhu W, Wang SQ (2000) Delignification of maize stems by peroxymonosulfuric acid, peroxyformic acid, peracetic acid, and hydrogen peroxide. 1. Physicochemical and structural characterization of the solubilized lignins. J Agr Food Chem 48:1253–1262

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340:97–106

Sundberg A, Strand L, Vahasalo B, Holmbom (2009) Phase distribution of resin and fatty acids in colloidal wood pitch emulsions at different pH-Levels. J Dispers Sci Technol 30:912–919

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–86

Terezo RF (2010) Technological evaluation of paricá and its use in laminated wood structures. Thesis (PhD in Structural Engineering) Federal University of Santa Catarina

Thakur MK, Gupta RK, Thakur VK (2014) Surface modification of cellulose using silane coupling agent. Carbohydr Polym 111:849–855

Tonoli GHD, Holtman KM, Glenn G, Fonseca AS, Wood D, Williams T, Sá VA, Torres L, Klamczynski A, Orts WJ (2016) Properties of cellulose micro/nanofibers obtained from eucalyptus pulp fiber treated with anaerobic digestate and high shear mixing. Cellulose 23:1239–1256

Velásquez-Cock J, Gañán P, Posada P et al (2016) Influence of combined mechanical treatments on the morphology and structure of cellulose nanofibrils: Thermal and mechanical properties of the resulting films. Ind Crop Prod 85:1–10

Viana LC (2013) Development of nanostructured cellulose films from the kraft pulp of Pinus sp. Thesis (PhD in Forest engineering) Federal University of Parana

Wang H, Li D, Zhang R (2013) Preparation of ultralong cellulose nanofibers and optically transparent nanopapers derived from waste corrugated paper pulp. BioResources 8:1374–1384

Wigell A, Brelid H, Theliander H (2007) Degradation/dissolution of softwood hemicellulose during alkaline cooking at different temperatures and alkali concentrations. Nord Pulp Pap Res J 22:488–494

Wise LE, Murphy M, D’Addieco AA (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap Trade J 122:35–43

Xie Y, Fu Q, Wang Q, Xiao Z, Militz H (2013) Effects of chemical modification on the mechanical properties of wood. Eur J Wood Prod 71:401–416

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Yu J, Paterson N, Blamey J, Millan M (2017) Cellulose, xylan and lignina interactions during pyrolysis of lignocellulosic biomass. Fuel 191:140–149

Yue Y, Han J, Han G, Zhang Q, French AD, Wu Q (2015) Characterization of cellulose I/II hybrid fibers isolated from energycane bagasse during the delignification process: morphology, crystallinity and percentage estimation. Carbohydr Polym 133:438–447

Zhang W, Zhang X, Lu C, Wang Y, Deng Y (2012) Flexible and transparent paper-based ionic diode fabricated from oppositely charged microfibrillated cellulose. J Phys Chem C 116:9227–9234

Zhao J, Zhang W, Zhang X, Zhang X, Lu C, Deng Y (2013) Extraction of cellulose nanofibrils from dry softwood pulp using high shear homogenization. Carbohydr Polym 97:695–702

Zuluaga R, Putaux JL, Javier Cruz J et al (2009) Cellulose microfibrils from banana rachis: effect of alkaline treatments on structural and morphological features. Carbohydr Polym 76:51–59

Acknowledgements

The authors thank the Fundação de Amparo à Pesquisa do Estado de Minas Gerais—FAPEMIG, Coordenacão de Aperfeiçoamento de Pessoa de Nível Superior—CAPES, Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq, Brazilian Research Network in Lignocellulosic Composites and Nanocomposites—RELIGAR.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Scatolino, M.V., Fonseca, C.S., da Silva Gomes, M. et al. How the surface wettability and modulus of elasticity of the Amazonian paricá nanofibrils films are affected by the chemical changes of the natural fibers. Eur. J. Wood Prod. 76, 1581–1594 (2018). https://doi.org/10.1007/s00107-018-1343-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1343-7