Abstract

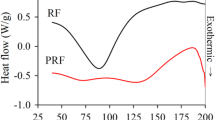

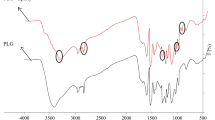

Epoxy resin is one of the most important thermosetting polymers. Most of the commercial epoxy resins are prepared by reacting bisphenol A with epichlorohydrin. However, epoxy resins have the drawback of being expensive. How to reduce manufacturing cost is an important issue. Solvent liquefaction is an effective method to convert biomass from solid to liquid. Phenol-liquefied wood contains a large amount of phenol structure which has the potential to react with the epoxide group of epoxy resin. In this study, wood of Cryptomeria japonica was liquefied in phenol with HCl and H2SO4 as a catalyst and named as LW-C and LW-S, respectively. These phenol-liquefied woods were mixed with epoxy resin to prepare blended resins. The curing behavior, thermal properties and wood bonding performance of blended epoxy resins with different weight mixing ratios were investigated. The results show that the gel time of blended resins can be shortened when compared with the neat epoxy resin, especially for those mixed with LW-S. DSC analysis shows blended epoxy resin prepared by mixing with LW-C has a heat flow variation similar to that of neat epoxy resin but a lower peak temperature with less heat released. Blended epoxy resins mixed with LW-C can be used as a wood adhesive to achieve a dry bonding strength similar to that of neat epoxy resin. These results indicated liquefied wood has the potential to prepare epoxy resin. However, the wet bonding strength is still necessary to further improve.

Similar content being viewed by others

References

Alma MH, Basturk MA (2006) Liquefaction of grapevine cane (Vitis vinisera L.) waste and its application to phenol–formaldehyde type adhesive. Ind Crops Prod 24:171–176

Asano T, Kobayashi M, Tomita B, Kajiyama M (2007) Syntheses and properties of liquefied products of ozone treated wood/epoxy resins having high wood contents. Holzforschung 61:14–18

Byrne CE, Nagle DC (1997) Carbonization of wood for advanced materials applications. Carbon 35:259–266

Chen F, Lu Z (2009) Liquefaction of wheat straw and preparation of rigid polyurethane foam from the liquefaction products. J Appl Polym Sci 111:508–516

Cherdoud-Chihani A, Mouzali M, Abadie MJM (2003) Study of crosslinking acid copolymer/DGEBA systems by FTIR. J Appl Polym Sci 87:2033–2051

Gao Y, Yu Y (2003) The synergistic effect of dicyandiamide and resorcinol in the curing of epoxy resins. J Appl Polym Sci 89:1869–1874

Kang CL, Lee WJ (2017) Properties of blended resins prepared by mixing epoxy resin with phenol-liquefied Cryptomeria japonica at different pH values. Q Jour Chin For 50(2):117–130 (In Chinese)

Kishi H, Fujita A, Miyazaki H, Matsuda S, Murakami A (2006) Synthesis of wood-based epoxy resins and their mechanical and adhesive properties. J Appl Polym Sci 102:2285–2292

Kishi H, Akamatsu Y, Noguchi M, Fujita A, Matsuda S, Nishida H (2011) Synthesis of epoxy resins from alcohol-liquefied wood and the mechanical properties of the cured resins. J Appl Polym Sci 120:745–751

Kobayashi M, Tukamoto K, Tomita B (2000) Application of liquefied wood to a new resin system—synthesis and properties of liquefied wood/epoxy resins. Holzforschung 54:93–97

Kobayashi M, Hatano Y, Tomita B (2001) Viscoelastic properties of liquefied wood/epoxy resin and its bond strength. Holzforschung 55:667–671

Kurimoto Y, Doi S, Tamura Y (1999) Species effects on wood-liquefaction in polyhydric alcohols. Holzforschung 53:617–622

Kurimoto Y, Takeda M, Koizumi A, Yamauchi S, Doi S, Tamura Y (2000) Mechanical properties of polyurethane films prepared from liquefied wood with polymeric MDI. Bioresour Technol 74:151–157

Kurimoto Y, Takeda M, Doi S, Tamura Y, Ono H (2001) Network structures and thermal properties of polyurethane films prepared from liquefied wood. Bioresour Technol 77:33–40

Laza JM, Bilbao E, Garay MT, Vilas JL, Rodríguez M, León LM (2008) Thermal properties and fire behaviour of materials produced from curing mixed epoxy and phenolic resins. Fire Mater 32:281–292

Lee WJ, Chen YC (2008) Novolak PF resins prepared from phenol liquefied Cryptomeria japonica and used in manufacturing moldings. Bioresour Technol 99:7247–7254

Lee WJ, Lin MS (2008) Preparation and application of polyurethane adhesives made from polyhydric alcohol liquefied Taiwan acacia and China fir. J Appl Polym Sci 109:23–31

Lee WJ, Kang CL, Chang KC, Chen YC (2012a) Synthesis and properties of resol-type phenol-formaldehyde resins prepared from H2SO4 – and HCl-catalyzed Holzforschung 66: 67–72

Lee WJ, Chang KC, Tseng IM (2012b) Properties of phenol-formaldehyde resins prepared from phenol-liquefied lignin. J Appl Polym Sci 124:4782–4788

Lee WJ, Kuo ES, Chao CY, Kao YP (2015) Properties of polyurethane (PUR) films prepared from liquefied wood (LW) and ethylene glycol (EG). Holzforschung 69:547–554

Lin L, Nakagame S, Yao Y, Shiraishi MY, Shiraishi NN (2001a) Liquefaction mechanism of β-O-4 lignin model compound in the presence of phenol under acid catalysis. Part 2. reaction behaviour and pathways. Holzforschung 55:625–630

Lin L, Yao Y, Shiraishi N (2001b) Liquefaction mechanism of β-O-4 lignin model compound in the presence of phenol under acid catalysis. part 1. identification of the reaction products. Holzforschung 55:617–624

Lin L, Yao Y, Yoshioka M, Shiraishi N (2004) Liquefaction mechanism of cellulose in the presence of phenol under acid catalysis. Carbohydr Polym 57:123–129

Mustata F (2011) Thermosetting resin compositions based on novolac and modified novolac. Adv Polym Tech 30:219–233

Okada H, Tokunaga T, Liu X, Takayanagi S, Matsushima A, Shimohigashi Y (2008) Direct evidence revealing structural elements essential for the high binding ability of bisphenol A to human estrogen-related receptor-gamma. Environ Health Perspect 116:32–38

Pan H (2011) Synthesis of polymers from organic solvent liquefied biomass: a review. Renew Sust Energ Rev 15:3454–3463

Pan H, Shupe TF, Hse CY (2009) Characterization of novolac type liquefied wood/phenol/formaldehyde (LWPF) resin. Eur J Wood Prod 67:427–437

Pérez JM, Rodríguez F, Alonso MV, Oliet M (2011) Time–temperature–transformation cure diagrams of phenol–formaldehyde and lignin–phenol–formaldehyde novolac resins. J Appl Polym Sci 119:2275–2282

Sjöström E (1993) Wood chemistry: fundamentals and applications. Academic Press, Cambridge

Tohmura SI, Li GY, Qin TF (2005) Preparation and characterization of wood polyalcohol-based isocyanate adhesives. J Appl Polym Sci 98:791–795

Ugovšek A, Sernek M (2013a) Characterisation of the curing of liquefied wood by rheometry, DEA and DSC. Wood Sci Technol 47:1099–1111

Ugovšek A, Sernek M (2013b) Effect of pressing parameters on the shear strength of beech specimens bonded with low solvent liquefied wood. J Adhes Sci Technol 27:182–195

Ugovšek A, Škapin AS, Humar M, Sernek M (2013) Microscopic analysis of the wood bond line using liquefied wood as adhesive. J Adhes Sci Technol 27:1247–1258

Wang T, Zhang L, Li D, Yin J, Wu S, Mao Z (2008) Mechanical properties of polyurethane foams prepared from liquefied corn stover with PAPI. Bioresour Technol 99:2265–2268

Wu CC, Lee WJ (2010) Synthesis and properties of copolymer epoxy resins prepared from copolymerization of bisphenol A, epichlorohydrin, and liquefied Dendrocalamus latiflorus. J Appl Polym Sci 116:2065–2073

Wu CC, Lee WJ (2011) Curing behavior and adhesion properties of epoxy resin blended with polyhydric alcohol-liquefied Cryptomeria japonica wood. Wood Sci Technol 45:559–571

Xie T, Chen F (2005) Fast liquefaction of bagasse in ethylene carbonate and preparation of epoxy resin from the liquefied product. J Appl Polym Sci 98:1961–1968

Yamada T, Aratani M, Kubo S, Ono H (2007) Chemical analysis of the product in acid-catalyzed solvolysis of cellulose using polyethylene glycol and ethylene carbonate. J Wood Sci 53:487–493

Yao Y, Yoshioka M, Shiraishi N (1996) Water-absorbing polyurethane foams from liquefied starch. J Appl Polym Sci 60:1939–1949

Yu CY, Lee WJ (2014) Characteristics of glycolysis products of polyurethane foams made with polyhydric alcohol liquefied Cryptomeria japonica wood. Polym Degrad Stab 101:60–64

Zou X, Qin T, Huang L, Zhang X, Yang Z, Wang Y (2009) Mechanisms and main regularities of biomass liquefaction with alcohol solvents. Energ Fuel 23:5213–5218

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, WJ., Kang, CL., Chen, YC. et al. Curing behavior and adhesion properties of epoxy resin blended with phenol-liquefied Cryptomeria japonica. Eur. J. Wood Prod. 76, 1563–1570 (2018). https://doi.org/10.1007/s00107-018-1329-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1329-5