Abstract

Three layer particleboards of 500 and 650 kg/m3 target density were made by spreading the core layer wood particles between upright positioned caul plates with the intention of partial vertical orientation. This procedure was assumed to increase the core layer compression resistance and, thus, counteract decreased panel properties in lightweight particleboard manufacture. While internal bond strength and thickness swelling were significantly improved, bending properties were on the same level as those of the references with conventional particle orientation. Density profiles were found to be just slightly more pronounced. The lack of improvements was explained by the changed structural set-up and, thus, lacking of core layer support.

Similar content being viewed by others

References

Benthien JT, Ohlmeyer M (2017) Influence of face-to-core layer ratio and core layer resin content on the properties of density-decreased particleboards. Eur J Wood Prod 75(1):55–62

Berggren P (2014) Industrialisierung moderner Leichtbauwerkstoffe für den Möbelbau [Industrialization of modern light-weight materials for furniture construction]. Leichtbau-Symposium, Herford, Germany, 4 December 2014. In: Benthien JT (2014) Mega-Trend, Zukunftsmusik oder Sackgasse? [Mega-trend, visions of the future or dead end?]. Holz-Zentralblatt 141(3):58–59

Dunky M, Niemz P (2002) Holzwerkstoffe und Leime—Technologie und Einflussfaktoren [Wood-based panels and adhesives—technology and influencing factors]. Springer, Berlin

Fahrni F (1942) Verfahren zur Herstellung von Kunstholzplatten [Method of producing artificial wood panels]. DBP 967328, 1942. In: Wyss O (1981) Zur Patentgeschichte der Spanplatte-Teil 1 [The history of particleboard patents-part 1]. Holz Roh Werkst 39:399–404

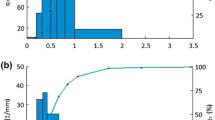

Plath E, Schnitzler E (1974) Das Rohdichteprofil als Beurteilungsmerkmal von Spanplatten [The density profile as assessment characteristic of particleboard]. Holz Roh Werkst 32:443–449

Wyss O (1981) Zur Patentgeschichte der Spanplatte [The history of particleboard patents]. Holz Roh Werkst 39:399–404

Acknowledgements

The authors thank the Fachagentur Nachwachsende Rohstoffe e.V. (FNR) (Gülzow, Germany) for its financial support. We also thank the research partner Stuttgart University, Institute of Machine Tools (IfW) (Stuttgart, Germany), especially Mr. Matthias Schneider, Mr. Dan Talpeanu and Dr.-Ing. Thomas Stehle. And also the industry partners Kronopol Sp z o.o. (Zary, Poland), especially Prof. Dr. Joachim Hasch and Mr. Maik Hirschberg; Leuco Ledermann GmbH & Co. KG (Horb am Neckar, Germany), especially Dr. Martin Dressler; and Pallmann Maschinenfabrik GmbH & Co. KG (Zweibrücken, Germany), especially Dr. Helmut Roll; for their involvement in the project. Special thanks go to all those persons who were engaged in the experimental realization and data analysis, namely Mrs. Dörte Bielenberg, Mrs. Sabrina Heldner, Mrs. Bettina Steffen, and Mr. Hannes Wagner (all Thünen Institute of Wood Research).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benthien, J.T., Ohlmeyer, M. Enhancement of low-density particleboard properties by core layer particle orientation. Eur. J. Wood Prod. 76, 1087–1091 (2018). https://doi.org/10.1007/s00107-017-1282-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1282-8