Abstract

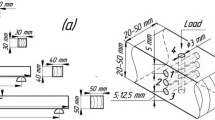

Drilling characteristics and quality of oil palm wood (OPW) for high grade furniture manufacturing were determined. The effects of diameter and rake angle of a Fortsner bit on the quality of drilling in treated OPW was investigated in comparison with untreated OPW and rubberwood. Boring qualities of treated OPW proved to be superior to untreated OPW but fell a bit below the quality shown by rubberwood. The 25 mm diameter bit outperformed the 32 mm diameter bit, while 30° rake angle outperformed 20° rake angle. Treated OPW and rubberwood are of the same class of surface quality with Ra value of 8.65 and 8.63 µm, respectively, while the untreated OPW is far inferior (14.28 µm). In conclusion, the treated OPW shows immense improvement in drilling quality compared to untreated OPW.

Similar content being viewed by others

References

ASTM-D 1666–87 (Reapproved 1994) American society for testing and material, standard method for conducting machining test of wood and wood based material, Annual book of ASTM standards. Vol. 04.09, Philadelphia, PA, pp 226–4

Chong YW, Bakar ES, Ashaari Z, Sahri MH (2010) Treatment of oil palm wood with low-molecular weight phenol formaldehyde resin and its planing characteristics. Wood Res J 1(1):7–12

Hesselbach J, Hoffmeister HW, Looh T (2007) Punching in industrial wood machining: an alternative production process to drilling. Prod Eng Res Develop 1:365–370

Hoadley RB (2000) Understanding wood: a craftsman’s guide to wood technology. The Taunton Press, Inc., Newtown, p 280

ISO 4288 (1996) Geometrical product specifications (GPS). Surface texture. Profile method. Rules and procedures for the assessment of surface texture. British Standards Institute, London

Jin W, Cai L (1996) Study and analysis on cutting forces of oblique cutting of wood. Holz Roh- Werkst 54(1996):283–286

Killman W, Fink D (1996) Coconut palm stem processing: technical handbook. Protrade, Eschborn, Germany

Koch P (1964) Wood machining processes. The Ronald Press Company, New York

Ratnasingam J, Ioras F (2012) Effect of heat treatment on the machining and other properties of rubberwood. Eur J Wood Prod 70:759–761

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bakar, E.S., Chong, Y.W., Anokye, R. et al. Effect of different diameters and rake angles of Forstner bit on the quality of drilling on treated oil palm wood. Eur. J. Wood Prod. 76, 369–374 (2018). https://doi.org/10.1007/s00107-016-1066-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1066-6