Abstract

Novolac type liquefied wood/phenol/formaldehyde (LWPF) resins were synthesized from liquefied wood and formaldehyde. The average molecular weight of the LWPF resin made from the liquefied wood reacted in an atmospheric three neck flask increased with increasing P/W ratio. However, it decreased with increasing phenol/wood ratio when using a sealed Parr reactor. On average, the LWPF resin made from the liquefied wood reacted in the Parr reactor had lower molecular weight than those from the atmospheric three neck flask. The infrared spectra of the LWPF resins were similar to that of the conventional novolac resin but showed a major difference at the 1800–1600 cm-1 region. These results indicate that liquefied wood could partially substitute phenol in the novolac resin synthesis. The composites with the liquefied wood resin from the sealed Parr reactor yielded higher thickness swelling than those with the liquefied wood resin from the three neck flask likely due to the hydrophilic wood components incorporated in it and the lower cross-link density than the liquefied wood resin from the three neck flask during the resin cure process.

Zusammenfassung

Novolakartige LWPF-Harze wurden aus verflüssigtem Holz und Formaldehyd synthetisch hergestellt. Das mittlere Molekülgewicht des LWPF-Harzes, das aus verflüssigtem Holz in einem atmosphärischen Dreihals-Kolben hergestellt worden war, nahm mit steigendem Phenol/Holz-Verhältnis (P/W) zu, wohingegen es bei der Herstellung in einem versiegelten Parr Reaktor mit steigendem P/W-Verhältnis abnahm. LWPF-Harz, das aus verflüssigtem Holz in einem Parr Reaktor hergestellt worden war, hatte durchschnittlich ein niedrigeres Molekülgewicht als LWPF-Harz, das in einem atmosphärischen Dreihals-Kolben hergestellt worden war. Die Infrarot-Spektren der LWPF-Harze ähnelten denjenigen von konventionellem Novolak Harz, unterschieden sich jedoch im 1800–1600 cm-1 Bereich deutlich. Diese Ergebnisse zeigen, dass das Phenol bei der Synthese von Novolak-Harz teilweise durch verflüssigtes Holz ersetzt werden kann. Verbundwerkstoffe mit LWPF-Harz, das aus verflüssigtem Holz im versiegelten Parr Reaktor hergestellt worden war, wiesen eine höhere Dickenquellung auf als diejenigen mit LWPF-Harz, das im Dreihals-Kolben hergestellt worden war. Der Grund besteht wahrscheinlich in den im Vergleich zu LWPF-Harz aus dem Dreihals-Kolben eingebundenen hydrophilen Holzbestandteilen und der niedrigeren Vernetzungsdichte während der Aushärtung.

Similar content being viewed by others

References

Alma MH, Yoshioka M, Yao Y, Shiraishi N (1995) Preparation of oxalic acid catalyzed resinified phenolated wood and its characterization. Mokuzai Gakkaishi 41(12):1122–31

Alma MH, Yoshioka M, Yao Y, Shiraishi N (1998) Preparation of sulfuric acid catalyzed phenolated wood resin. Wood Sci Technol 32:297–308

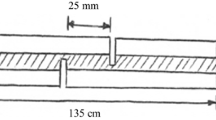

American Society for Testing and Materials (ASTM) (1996) Standard test method for evaluating properties of wood-base fiber and particle panel materials. ASTM D 1037-96

Costa L, Montelera LR, Camino G, Weil ED, Pearce EM (1997) Structure-charring relationship in phenol-formaldehyde type resins. Polym Degrad Stab 56:23–35

Crews P, Rodriguez J, Jaspars M (1998) Organic structure analysis. Oxford university press, New York

Hasllam J, Willis HA (1965) Identification and analysis of plastics. D Van Nosrand company, Inc., Princeton, New Jersey

Holopainen T, Alivila L, Rainio J, Pakkanen TT (1998) IR spectroscopy as a quantitative and predictive analysis method of phenol-formaldehyde resol resins. J Appl Polym Sci 69:2175–2185

Kristkova M, Filip P, Weiss Z, Peter R (2004) Influence of metals on the phenol-formaldehyde resin degradation in friction composites. Polym Degrad Stab 84:49–60

Lee SH, Yoshioka M, Shiraishi N (2000) Preparation and properties of phenolated corn bran/phenol/formaldehyde co-condensed resin. J Appl Polym Sci 77:2901–2907

Lin L, Yoshioka M, Yao Y, Shiraishi N (1995a) Preparation and properties of phenolated wood/phenol/formaldehyde cocondensed resin. J Appl Polym Sci 58:1297–1304

Lin L, Yoshioka M, Yao Y, Shiraishi N (1995b) Physical properties of moldings from liquefied wood resins. J Appl Polym Sci 55:1563–1571

Lin L, Yao Y, Yoshioka M, Shiraishi N (2001) Liquefaction mechanism of β-O-4 lignin model compound in the presence of phenol under acid catalysis. I. Structural characterization of the reaction products. Holzforschung 55:617–624

Myers GE, Christiansen AW, Geimer RL, Follensbee RA, Koutsky JA (1991) Phenol-formaldehyde resin curing and bonding in steam-injection pressing. I. Resin synthesis, characterization, and cure behavior. J Appl Polym Sci 43:237–250

Pan H, Shupe FT, Hse CY (2005) Preliminary investigation of bio-composites fabricated from liquefied wood/phenol/formaldehyde co-condensed resin. In: Frihart C (ed) Wood adhesives 2005. Forest Product Society, Madison, pp 257–262

Pan H, Shupe FT, Hse CY (2007) Characterization of liquefied wood residues from different liquefaction conditions. J Appl Polym Sci 105:3739–3746

Pan H, Shupe FT, Hse CY (2008) Synthesis and cure kinetics of liquefied wood/phenol/formaldehyde resins. J Appl Polym Sci 108:1837–1844

Pecsok RL, Shield LD (1968) Modern methods of chemical analysis. John Wiley & sons, New York

Poljansek I, Krajnc M (2005) Characterization of phenol-formaldehyde prepolymer resins by in line FT-IR spectroscopy. Acta Chim Slov 52:238–244

Pu S, Shiraishi N (1993) Liquefaction of wood without a catalyst I. time course of wood liquefaction with phenols and effects of wood/phenol ratios. Mokuzai Gakkaishi 39(4):446–452

Rezzoug SA, Capart R (1996) Solvolysis and hydrotreatment of wood to provide fuel. Biomass Bioenerg 11(4):343–352

Rezzoug SA, Capart R (2002) Liquefaction of wood in two successive steps: solvolysis in ethylene-glycol and catalytic hydrotreatment. Appl Energ 72:631–644

Rustamov VR, Abdullayev KM, Samedov EA (1998) Biomass conversion to liquid fuel by two-stage thermochemical cycle. Energ Convers Manag 39(9):869–875

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, H., Shupe, T.F. & Hse, CY. Characterization of novolac type liquefied wood/phenol/formaldehyde (LWPF) resin . Eur. J. Wood Prod. 67, 427–437 (2009). https://doi.org/10.1007/s00107-009-0337-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-009-0337-x