Abstract

Natural green compounds for sensor modification (binders) are challenging in electrochemistry. Starch is a carbohydrate biopolymer that has been used extensively in the development of biomaterials for the food industry due to its ability to impart textural characteristics and provide gelling or film formation. In particular, the excellent film-forming characteristics have been used for the development of new surface modifying architectures for electrodes. Here, we highlight a very comprehensive overview of the properties of interest of various types of starch in conjunction with (bio)materials in the chemical modification of sensors and biosensors. Throughout the review, we first give an introduction to the extraction, applications, and properties of starches followed by an overview of the prospects and their possible applications in electrochemical sensors and biosensors. In this context, we discuss some important characteristics of starches and different strategies of their film formation with an emphasis on their role in the development of electrochemical sensors and biosensors highlighting their main contributions to enhancing the performance of these devices and their applications in environmental and clinical samples.

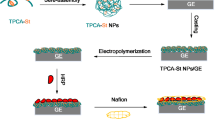

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The core of the world’s sustainable development unquestionably includes the intelligent use and reuse of everything we have at our disposal mainly through physical and/or chemical modifications of the properties of these materials. Furthermore, it is necessary to optimize all the processes in a scalable production chain continuously seeking materials that present multifunctionality in the sector, low complexity and operational cost, and that are preferably environmentally friendly [1].

Conventional analytical instruments such as mass spectrometry (MS), chromatography, Atomic Absorption Spectroscopy, Ultraviolet–visible spectroscopy, and Nuclear Magnetic Resonance (NMR), among others, are the main means of analysis and diagnostics, used for example to monitoring in different fields such as the food industry, medicine, and clinical biology due to their reliability and great performance. These analytical instruments have a series of qualities, such as excellent sensitivity, high selectivity, and robustness. However, they are generally very expensive, complex, require highly qualified operators and sophisticated laboratory structures [2]. The current Polymerase Chain Reaction (PCR) tests applied for the detection of SARS-CoV-2 (COVID-19) are a good example of how conventional procedures work, almost always marked by the need for several steps, equipment, and expensive reagents that culminate in time-consuming and equally costly analyses [3, 4]. In this context, the search for new instruments and means of analysis that can circumvent these problems has intensified in recent decades. The search and development of new analytical devices have shown excellent results and high potential products, such as optical, fluorescent, colorimetric, and electrochemical devices [3,4,5,6,7]. In this aspect, the use of electrochemical techniques can be highlighted, being an alternative to conventional analytical methods, since they have several advantages which are currently required, mainly concerning cost, simplicity, miniaturization/portability capacity, and the possibility of on-site application [8,9,10,11]. A clear example of the effectiveness of the application of electrochemical devices is glucose sensors, which are well-established and highly employed as point-of-care devices [12, 13].

Devices based on electrochemical sensors and biosensors are an excellent alternative to this demand. The electrochemical techniques combine outstanding properties such as high sensitivity, fast response time, reduced cost, instrument simplicity, the possibility of miniaturization, and integration into portable devices [14]. Furthermore, electrochemical devices have great mechanical and chemical robustness that can be easily enhanced by modifications to the electrode surface, for example [15,16,17,18,19].

Traditional electrodes, in some situations, do not present selectivity, accuracy, and reproducibility to be used directly in electrochemical sensing. In this context, an alternative is the introduction of electroactive layers that must anchor over an electrode surface. As a consequence, is produced a chemically modified electrode. The concept of chemically modified electrodes (CMEs) was first introduced by Royce Murray in the 1970s, who at the time used amine groups were used to modify a SnO2 electrode [20]. The anchoring of the modifying molecules on the surface of the substrate material with the aid of a binder gives the CMEs and can be carried out by covalent or non-covalent bonding. In addition, the anchoring of specific functional groups provides a pathway for the interaction with the target analyte and is directly correlated with the nature of the ongoing analytical study [21].

The choice of the anchor/binding molecule is a very important step in the study and application of modified electrodes (MEs) since all electrochemical reactions occur at the electrode/solution interface. Therefore, the surface structure of the electrode at the interface has a distinct role in the reaction of the electrode and facilitates the pathway for the transfer of electrons at the interface which, in addition, provides the best electrode kinetics [22].

Starch is a natural food carbohydrate, very abundant, easy and cheap to extract, non-toxic, biodegradable and it is the most abundant biopolymer in the world after cellulose [23]. Two types of polysaccharides with only two types of linkages in the chain constitute almost 100% of the total content of most starches, namely amylose a linear polymer formed by glucose residues (between 15 and 25%), and amylopectin the major glucan (75–85%) highly branched and of high molecular weight. As a result of their almost total structure consisting of homopolymers of units α-D-glucopyranosyl, the starches present a single reactive functional group, which is not a hindrance for them to undergo numerous chemical and physical modifications [24]. The small quantities of non-carbohydrate in the structure of starches, particularly lipids, proteins, and phosphorus also play an important role in their physical–chemical and functional properties [25]. This structure thus allows numerous chemical and physical modifications and can support a succession of chemical reactions and physical treatments such as oxidation [26], fermentation [27], grafting [28], crosslinking [29], pre-gelatinization processes [30], hydrothermal processes [31], multiple deep freezing and thawing [32], and mechanical activation-with stirring ball mill [33]. The functional properties of starch films can be enhanced when combined with these modifications.

The properties of the starch gel are directly correlated with the solubility of its constituent homopolymers. High levels of soluble amylose and strong association in the network result in increased starch elasticity, while high levels of soluble amylopectin are detrimental to starch gel formation and elasticity [34]. These unique properties make starch suitable for a wide range of applications in food, pharmaceutical, cosmetic, adhesive, plastic, agrochemical, medical [35], and most recently in the field of sensors and biosensors [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50]. In addition, the biodegradability of starches and its obtention from natural sources makes the use of this material an excellent alternative to minimize environmental impacts by contributing to the reduction of waste [51, 52]. The hydroxyl groups present in the polysaccharide chains of amylose and amylopectin confer flexibility, the excellent capacity for film formation, good adhesion, biocompatibility, high mechanical resistance, and the possibility of suffering structural modifications [53, 54], which make it the appropriate starch to modify and build electrochemical sensors. Pre-gelatinization processes and acetylation reactions improve the functional properties of starch such as solubility and stability in a wide range of temperature and pH changes [55, 56]. Simple methods like wet chemical synthesis and drop-casting have been used to successfully produce modified starch-based electrodes.

This review describes how electrochemical sensors can be obtained from a simple modification on their surface with starch associated with other modifiers. First of all, the extraction processes, applications, and properties of starches are introduced. Then we move to focus on the applications and discussion of modified electrodes with starches for analysis of various target analytes between 2017 and 2021.

Starch: Natural Origin, Extraction, and General Application

Structure and Sources of Starch

Starch is the main source of carbohydrates for humans [57] and has been part of our diet and life since prehistoric times [58]. Egyptians and Romans already used this substance for different purposes [59]. The major constituents of starch are two different carbohydrates polymer: amylose and amylopectin. Amylose is a linear polysaccharide with α-(1–4)-linked d-glucose units. However, depending on the molecular weight, amylose molecules may contain ten or more branches. In contrast, amylopectin molecules are highly branched., with α-(1–4)-linked d-glucose backbones and exhibits about 5% of α-(1–6)-linked branches, which have a prominent effect on some starch properties (Fig. 1).

Basic structural motifs of amylose and amylopectin, along with the labeling of the atoms and torsion angles. Extension of the basic motifs to macromolecular structures [59]

Starch granules can be found in different parts of the plant, such as seeds, flowers, stems roots, and tubers, and constitute an important energy reserve for them [61]. One of the most important properties of starch is the relative amount of its two main polysaccharides: amylose and amylopectin [62]. In this way, determining the amylose/amylopectin proportion is of fundamental importance for understanding the expected starches' properties [63, 64].

Starch Extraction Sources

Usually, the starch extraction method is linked to its source. In this review, we will focus on the extraction of starch in potatoes and cassava, which are the types of starches most used in the production of electrochemical sensors and biosensors.

Potato Starch

Potato is one of the cheapest, most abundant, and ubiquitous food crops used across the globe and the fourth most produced behind rice, wheat, and corn [65]. In terms of production, half of the world’s production is consumed fresh, and the rest is used in the food industry for various purposes such as flour, snacks, flakes, and starch [66].

The extraction of potato starch (PS) occurs directly through the tissue structure due to the low content of proteins and lipids (values below 4%). For the extraction of PS, the steps involved are milling, decantation, centrifugation, successive washes of the starch with distilled water, and drying. During the milling step, sodium metabisulfite is added to repress the oxidation of tyrosine (Tyr), dihydroxyphenylalanine, and/or chlorogenic acid as catalyzed by polyphenol oxidase and prevents the formation of melanin, which has a red-brown color.

The amount of PS extracted is also influenced by the speed of rotation and time of extraction. In an experiment carried out by Altemimi and colleagues [67] the spin speed (ranging from 1000 to 3000 rpm) and time of extraction (ranging from 5 to 15 min) were used to evaluate the starch extraction yield in potatoes. The results showed that the samples processing at 3000 rpm and 15 min resulted in the highest yield of extracted starch when compared to 1000 rpm of rotation speed.

Cassava Starch

Cassava also known as tapioca, manioc, or yucca is a tropical and sub-tropical crop with high tolerance to drought, harsh climatic conditions, and high productivity in poor soils [68]. With a starch-rich tuberous root, cassava provides a good source of carbohydrates. Furthermore, cassava is the second most important botanical source of industrial starch, behind corn [69].

When compared to other sources of starch, cassava starch (CS) is one of the easiest to extract, mainly because its tubers contain a very low quantity of proteins and fats, and lower amylose content than other amylose‐containing starches, and high molecular weights of amylose and amylopectin [70].

For CS, extraction of fresh roots is used, at first, they are washed, then chopped and grated in sulfur‐containing water to separate the starch from the pulp in the extractor. After this, the starch fraction is separated from the pulp and de‐watered before drying. Before drying the starch, it can be stored in a Na2S2O5 solution to inhibit microbial growth [71]. Likewise, for PS, there are several extraction methods for CS, from the most rudimentary such as those developed by indigenous peoples to the most sophisticated ones developed in research laboratories.

Properties of Starch

Analytical and Structural Aspects

The two major polymers in starches, amylose, and amylopectin have different properties. While amylose results in robust films and hard gels due to its high memory leak, amylopectin in aqueous media produces films and gels with opposite characteristics due to their greater stability. Another important element is the intertwining between the amylose and amylopectin molecules. It has been found that when this entanglement is done in the presence of lipids and phospholipids properties such as pasting temperature, viscosity, and retrogradation rate of pastes, for example, are considerably affected. In addition, other components of starch that are found in small amounts in granules, such as phosphate ester groups and free fatty acids, also significantly affect the properties of starch pastes and gels [72, 73].

Molar Mass (MM), Granules Features, and Crystallinity of Starch

Molar mass (MM) is one of the most fundamental parameters in the characterization of a polymer. For starches that are known to be formed mainly by two types of polymers, it can be said that the average molar mass and molar mass distribution are important properties. The molecular mass of starch is an important characteristic influencing the retrogradation properties [74] and their conditions of implementation. The determination of MM can be done by size-exclusion chromatography (SEC) [75] or by field-flow fractionation (FFF) [76].

The stability and physical properties of starch materials are largely dependent on the nature of the amorphous and crystalline domains present in native granules or processed starch materials. The outer surface of granules from most of the existing starches is the main barrier to processes that directly affect their properties, such as enzyme attacks and chemical reactions with modifying agents. Figure 2 shows some typical surface morphology of the starches samples as revealed using scanning electron microscopy (SEM). [77] described this morphology as a hairy billiard ball. Understanding the surface chemistry of starch granules is an important step toward improvements in electrochemical applications such as sensors and biosensors. The crystallinity is also important because it allows the control of a certain number of properties such as gelatinization, water content, stability of polymorphs, and even how amylose and amylopectin are distributed in the starch granules. X-ray diffraction is the main technique used to determine the crystallinity of the granules. The experiments carried out so far show that four different X-ray diffraction patterns were obtained for the most diverse types of starches. These patterns are designated by A, B, C, and V-pattern and can be assigned as follows: [78].

-

A-pattern: cereal starches (except high-amylose varieties);

-

B-pattern: root, tubular starches (and for high-amylose varieties) and retrograded starch;

-

C-pattern: beans and peas;

-

V-pattern: gelatinized lipid-containing starches;

Raw starch granules observed by scanning electron microscopy: A potato; B cassava; and C rice starches. The corresponding granules under polarized light are shown in insets. D shows SEM of in situ granules in potato parenchyma cell [81] (Reprinted from Pérez et al., 2009, with permission of Elsevier)

In general, the degree of crystallinity is associated with the presence of water in the granule and the presence of a greater amount of crystalline domains can be observed for granules with an intermediate amount of water. These crystalline domains are mainly made up of amylopectin molecules, with the double helices arranged in the A, B, or C-pattern. [79, 80].

Starch Modification

Several properties of starch including texture, retrogradation, film formation, and adhesion can be improved by its modification. The starch molecule can be modified physically and chemically, depending on the purpose or applicability for which it is intended [82]. Physical modifications are generally easier, safer, and cheaper since they do not use chemical or biological inputs [83]. In addition, most native starches have great instability when exposed to different temperatures, shear, and pH conditions. In this way, it is necessary to modify their structure to increase their range of applications [84].

Physical Modification of Starches

Different particle sizes and stability in water are the main changes brought by the physical modification of starch. These modifications directly impact properties such as retrogradation, shear, solubility, and gelatinization and generally employ a variety of techniques such as hydrothermal processes [85], mechanical activation with stirring ball mill [33], superheated starch [86], and pulsed electric fields (PEF) treatment [87].

The hydrothermal treatment causes changes in the properties of starch, allowing interactions between starch chains and contributing to improving crystalline perfection. Other physical treatments, such as repeated freezing and thawing of starch paste make the starch resistant to digestibility and can be used as an alternative source of nutrients for diabetic patients as well as in the making of polymeric rate control films in controlled drug delivery systems [88].

Chemical Modification of Starches

Chemical modifications in the molecular structure of starches are usually linked to hydroxyl groupings derived mainly from amylose and amylopectin carbohydrates and involve the insertion of functional groupings into these molecules which ultimately result in significant changes in the physical–chemical properties of starches [82].

The chemical reactivity of starches is strongly linked with the hydroxyl groups in the carbons in free positions (C-2, C-3, and C-6) from the glycosidic bond linkages and pyranose ring formation. In this way, the starches can for example have their chains separated by hydrolytic cleavage at the glycosidic bonds; C–C bond creating carbonyl groups, or oxidative reaction with the -OH. Other varied reactions with functional and multifunctional reagents also can produce a large class of modified starches, which are called “starch derivatives” [89].

Various techniques for the chemical modification of starches are shown in Table 1. Although most of the chemical modifications are intended to make the starch more available for applications in the food industry, starches have found application in the most varied industrial segments of the non-food sector such as drugs [90], paper [91], building [92], biodegradable materials [93], and adhesive gums [94] industries.

Starch Solubility

The solubility of starches is influenced by several factors, such as the ratio between their main constituents, namely amylose and amylopectin, phospholipids and phosphate groups, etc. [78]. The solubility of amylose is variable in the water while the amylopectin is soluble as a function of the highly branched structure [105]. Amylose and amylopectin can interact with phospholipids present in starch and form complexes that decrease the solubility of starch granules [54]. On the other hand, the presence of phosphate groups in some types of starch such as PS increases the swelling capacity of starch granules and consequently its solubility [106].

Although most starch molecules have no charge (except for starches that contain phosphate groups), the pH has some influence on the solubility of starch granules. Starch granules exposed to solutions with low pH suffer hydrolysis, already at high pH a gelatinization may occur [107]. Amylose is solubilized in NaOH solution at room temperature as a consequence of starch granules swell [108].

Since starches are poorly soluble in water and the most common organic solvents, strategies for modifying starches in an aqueous solution have been developed. Among these modifications, we can highlight acetylation. Acetylated starch is commonly obtained by esterification of native starch with replacement of hydroxyl groups by acetyl groups in starch molecules leading to a structural reorganization owing to steric hindrance; as a result, the repulsion between starch molecules, thus facilitating an increase in water percolation within the amorphous regions of the granules and a consequent increase in solubility [106, 109].

Starch Stability

Stability is one of the functional properties of starch that also depends on the molecular structure of its components, especially amylose and amylopectin. The native starch usually needs to go through some kind of modifications, be it physical or chemical, to become stable for the various applications that the starch finds in the food and non-food industries.

Pre-gelatinized Starch

It is well-known that in aqueous solution native starches present retrogradation, low solubility, and are unstable [54]. Modifications in starch like those introduced by physical methods such as drum dryer, extrusion, and spray-dryer tend to promote a rapid gelatinization of starch and produce pre-gelatinized starches [109, 110].

Pre-gelatinized starches exhibit excellent cold water solubility, long-term stability, and low retrogradation, and when compared to untreated starch they are easily dispersed in the water-forming gel at room temperature and are less subject to precipitate formation [111].

Temperature and pH

Chemical modifications such as etherification, acetylation, oxidation, and crosslinking are the main routes used to obtain stable starches at temperature and pH variations [112,113,114,115]. In all cases, the starch stability is achieved from structural modifications with the addition of specific functional groups and/or breakdown and creation of new bonds that lead to changes in starch polarity and interruption of the linearity of amylose and the ramified portion of amylopectin [116].

Starch in Electrochemical Sensors and Biosensors

The optimization of electrochemical devices looks for materials that besides offering an increase in sensitivity and stability can also be eco-friendly and cheap to extract or synthesize. In this scenario, starches have gained space in the development of electrochemical sensing platforms, as we will see in this section. From 2017 to 2021, 22 articles have been reported in the literature on the use of starch in the modification of electrochemical sensors, the distribution of these articles over the years can be seen in Fig. 3.

As can be seen in Fig. 3, the largest number of published articles are concentrated in the years 2017 to 2019. In addition, in the following years, the number of works involving starches as a modifier for electrochemical sensors decreased. This decrease can be attributed to the beginning of the SARS-CoV-2 pandemics, which consequently led to periods of lockdown around the world, affecting the functioning of research laboratories. Nevertheless, the use of starch still has an enormous potential for application as a modifier compound to be explored, since the development of new electrochemical sensors has expanded a lot in recent years, mainly with the development of new platforms, whether they are 3D printed or low-cost devices. Thus, the use of starch as a tool for modifying electrochemical sensors still has much to be researched and used, since its characteristics, such as being easy to obtain, low cost, renewable and eco-friendly, bring enormous advantages. The use of green materials in the development of sensors is a great alternative for reducing the use of toxic and hazardous reagents and minimizing environmental impacts [117]. In this regard, starch can be highlighted as a biodegradable, non-toxic, and sustainable material, which can contribute to the reduction of toxic waste, and has been (poorly) explored in the construction of sensing platforms. A list of works related to starch-based sensors and biosensors is shown in Table 2, highlighting the main characteristics of the methods developed and the analytes of interest. The main starches reported in the use of sensor modifiers are potato and cassava. Different strategies have been used in the incorporation of starch into other electroactive materials such as by producing/mixing with nanoparticles, carbon black, graphene, nanodiamonds, and enzymes, for the proposition of sensors and biosensors.

Starch (Bio)sensors Based on Potato

Starch from potatoes has a high percentage of phosphate groups in its structure when compared to other starches, which is favorable for chemical modifications that produce derivatives with high solubility [129]. In addition, the presence of high molecular weight amylose and properties such as low gelatinization temperature and a high paste consistency leads to the formation of good films, with moderate mechanical resistance, chemical stability, and excellent biocompatibility [130, 131].

An interesting method of producing carbon microspheres (CM) from PS proposed by Lin 2017 [45] was used to produce modified glassy carbon electrodes (GCE) and applied for the detection of Hg(II) in river water specimens. The mild hydrothermal method was employed to fabricate the CM with high dispersion through carbonization under high temperature with N2. For this, PS was solubilized and stirred for 5 h. Subsequently autoclaved at 180 ºC for 16 h and finally cooled to room temperature. The products were filtered and purified with ethanol and water, then dried under a vacuum. Finally, the sample was placed in the oven at a heating rate of 4 ºC/min and treated under N2. According to the authors, the sensor produced showed excellent reproducibility, low interference from other metal ions, and a stable use time of one week with efficiency.

The determination of estriol hormone in environmental and biological samples using a modified carbon electrode with PS, reduced graphene oxide (RGO), and gold nanoparticles were investigated recently by Jodar et al., 2018 [41]. In this study, PS was described for the first time as a modifying agent and also as an anchor of an electrochemical sensor. The soluble PS was prepared and mixed with RGO and GNPs dispersion and added by drop cast on the surface of the GCE. The solvent was evaporated for 20 min at room temperature. Thus, thin and stable films were obtained on the surface of the working electrode, which showed an excellent electrochemical response for the detection of estriol.

Delgado and colleagues [40] developed a modified ultralow-cost electrochemical sensor (< US$ 0.005 per unit of sensing layer) based on a homogeneous thin film of PS and carbon black (CB) deposited on GCE for detection of tetracycline in water and milk. Their investigations showed that the addition of CB leads to an increase in film porosity, indicating an increase in conductivity for CB-PS films. More expressively, it was shown that CB-PS films even when submitted to more than twenty consecutive measurements showed no change in their performance. Furthermore, the authors report that the CB-PS/GCE electrodes are reproducible and stable and can serve as a new generic platform for detecting other antibiotics and hormones whose redox potentials are similar to those of tetracycline.

In 2018, Gautam and co-workers [118] built a new modified carbon paste electrode (CPE) with conductive polymer-based composite, MWCNTs, and PS for non-enzymatic cholesterol determination in a real cow's milk sample. The composite material was prepared by chemical polymerization in situ of aniline in PS suspension and MWCNTs using 0.1 M HCl and ammonium peroxydisulfate. The high sensitivity and lower redox potential for electrocatalytic oxidation of cholesterol were assigned to the interaction with the material with emphasis on the interactions between the sugar chains of starch and the cholesterol molecules. The developed sensor had a high sensitivity (800 μA mM−1 cm−2), an extremely low analysis time (4 to 6 s), and a high selectivity compared to other tested analytes according to the authors. The same group has used the same electrode modifier material as the basis for the development of biosensors for peroxide and glucose detection [48]. In this work, the determination of hydrogen peroxide by using the CPE modified with polyaniline/multiwall carbon nanotubes/starch and hemoglobin. The developed ternary composite system has multiple interactions and enhanced synergistic properties-high surface area, good electroactivity, conductivity, stable dispersion, and biocompatible. Also, the authors claim that this developed material could be used as a platform to develop some other sensors using other redox enzymes, such as the detection of glucose described in the work as a specimen. Thus, the favorable properties indicate that the proposed material system is suitable for the manufacture of low-cost sensors.

Phenolic compounds are probably one of the most studied classes of natural compounds [132]. To counterbalance those that present benefits to human health, many other phenolic compounds such as catechol even when present in micromolar concentrations, are toxic to the human body. An electrochemical biosensor based on carbon nanodiamonds (NDs) and PS for the determination of catechol was proposed by Camargo et al. [42]. As a proof of concept, the ND/PS film served as a matrix to immobilize Tyrosinase, in which the proposed biosensor was suitable for detecting catechol in river and tap water samples. The method of preparation of the dispersion of PS application was the same indicated in the work described previously [41]. The NDs were added in the proportion 1:1 (w/v) of the PS dispersion and 5 mL of the resulting solution were added to the surface of the GCE and left to dry at room temperature for 12 h. Furthermore, the authors reported that the ND-PS matrix might have its use extended to immobilize other enzymes and biomolecules, thus representing a potential biocompatible platform for ubiquitous biosensing.

Modified CPE with copper sulfide nanoparticles (CuS NPs) was prepared by the simple method of co-precipitation in an aqueous medium using starch as a biopolymer (CuS NPs/MCPE). These interesting NPs CuS were developed for caffeine determination by differential pulse voltammetric (DPV) [49]. CuS NPs were prepared in the solution phase by the co-precipitation method. Subsequently, the starch was solubilized in water heated to 75 °C and according to the authors, when it is heated, the semicrystalline structure of the starch is lost. Thus, after adding the Cu(II) solution, copper cations are attracted to the O–H groups of the starch to form Cu(OH)2. Then, sodium sulfide is added to form a black CuS precipitate. The global chemical equation of the production method can be observed below:

After the development of the modified electrode, the authors used DPV for the determination of caffeine in real samples. The modified electrode proved to be able to be used as a good sensor for several electroactive species in the field of electroanalysis. Another interesting work was presented by the same research group following the same modification method using PS. Thereat, a new electrochemical sensor based on zinc oxide nanoparticles (ZnO-NPs/MGCE) electrode was developed to determine caffeine again [120]. The electrochemical sensor was modified with ZnO-NPs following the same general Eq. (1). The method of determination used was DPV and successfully managed to determine caffeine in samples of commercial beverages with recovery values of 102 to 106%.

An electrochemical sensor for epinephrine in blood plasma was developed by anchoring a molecularly imprinted polymer (molecularly imprinted polymers (MIP)) matrix on the surface of a gold-coated quartz crystal electrode of electrochemical quartz crystal microbalance (EQCM) using PS nanoparticles (Starch NP) and RGO nanocomposite [119]. The MIP sensor was designed by electroplating the NP-RGO starch composite on the EQCM electrode in the presence of the EP model. The authors emphasize that the developed sensor is environmentally friendly with high sensitivity and good selectivity, which can be applied in “real” matrices easily and practically.

A comparison between sensors modified with cobalt nanoparticles in the presence of cellulose and PS for the determination of paracetamol in a pharmaceutical formulation in the presence of warfarin and caffeine was proposed by Azab et al., 2019 [46]. The difference between the behavior of the two polymers (cellulose and starch) was investigated electrochemically through voltammetric and spectroscopic impedance measurements. The procedure used was based on the mixture of nujol oil and soluble starch/cellulose to modify the CGE. The experimental procedure for producing the CPE/C, CPE/S, CPE/C//NanoCo, and CPE/S//NanoCo performed is shown in Fig. 4.

Schematic model of the methodology for producing the modified carbon paste electrodes [46] (Adapted by Azab 2019)

In another work, Srivastava et al. [121], presented an electrochemical sensor based on gold-coated quartz crystal microbalance (EQCM) with a surface modified with MIP using starch nanoparticles and graphite oxide nanocomposite reduced. As a proof of concept, the electrochemical sensor was tested for transferrin detection in real human blood plasma samples. The preparation of starch nanoparticles was performed using the ionotropic gelation method. For this, initially, a solution of 0.1% starch (w/v) in water, was kept under heating and constant stirring for 5 h. For fabrication of the final electrode, the starch-graphene nanocomposite with an analyte molecule (transferrin) was electrodeposited on the surface of the gold-coated EQCM electrode via cyclic voltammetry (CV). The fabrication scheme of the compounds described above is shown in Fig. 5. Finally, the authors applied the sensor to determine transferrin in blood plasma which provided satisfactory responses that demonstrate the effectiveness and feasibility of the developed sensor.

Schematic representation for fabrication of starch nanoparticle—RGO composite molecularly imprinted polymer [121] (Reprinted from Srivastava et al., 2019 with permission of Elsevier)

Zou et al. [122] developed a GCE electrochemical sensor based on two polysaccharides, soluble starch (SS) and chitosan (CS) for the detection of Tyr enantiomers. For the preparation of the working electrode, the SS was dispersed in water and heated at 130 °C for 30 min. For a better design, an illustrative scheme of the experimental procedure and the images obtained by electronic scanning microscopy of the sensor modified with SS and CS can be seen in Fig. 6. According to the authors, the SS-CS composite itself has a porous lattice structure. In this way, the composite present on the surface of the CGE could also be used as an attractive chiral model for the recognition of Tyr enantiomers due to the chiral characteristics of the two polysaccharides. The sensor was tested on a series of interfering compounds to demonstrate selectivity, and the compounds did not exhibit any significant interferences. Finally, Tyr was determined in a racemic solution, demonstrating a good efficiency of the starch-modified electrochemical sensor.

The schematic diagram of the experimental procedure: 1A The preparation of SS-CS/GCE; 1B The proposed mechanism for the chiral electrochemical recognition of Tyr enantiomers on SS-CS/GCE. 2 Characterization, 2A FE-SEM image of SS-CS/GCE shows a uniform surface due to the dispersion of the composite on the surface of the GCE forming a very smooth planar film; B FE-SEM image of SS-CS composite, which has a porous network structure [122] (Reprinted from Zou et al., 2019 with permission of Elsevier)

Ramu et al. [123], presented a work demonstrating the use of starch in a different way, which aims to obtain nanoparticles of γ-Fe2O3 (maghemite) with starch aid to modify a CGE. The electrochemical sensor was used in the determination of folic acid in pharmaceutical samples. For the production of nanoparticles, initially, a 2:1 molar ratio solution of ferric chloride hexahydrate and ferrous sulfate heptahydrate solutions were prepared, then the starch solution was added under constant stirring at a temperature of 60 °C until obtaining a brownish-black precipitate. The precipitate was removed, washed several times, and dried, then pulverized and calcined to obtain the desired nanoparticles. The nanoparticles were dispersed in distilled water and ultra-sonicated to obtain a homogeneous suspension. Finally, for the modification of the CGE, the suspension was deposited on the electrode surface and dried at room temperature. The determination in a pharmaceutical sample was performed through the recovery test, obtaining values between 96 and 101%, demonstrating that there was no significant matrix presence. Thus, the authors emphasize that the sensor demonstrates great potential, mainly because it uses a simple and ecologically correct modification.

Sayka et al. [124], described the synthesis of an unusually modified starch (CL starch), employing succinic anhydride, and evaluated if the proposed starch influenced the electrochemical response of carbon paste electrodes The mixture was homogenized, and the carbon paste formed (CPE/CL) was packed into the cavity of a Teflon tube provided with a copper electrical contact. More promising electrochemical features were obtained using CL starch than bare CPE or CPE containing unmodified starch, attributed to the lower hydrophilic character presented by CPE/CL, resulting in a lower background current. This shows that even the modification of PS is capable of providing good electrochemical sensors.

Starch (Bio)sensors Based on Casava

The use of starch as a modifier and anchor of electrochemical sensors is an area of research still poorly explored, but it has recently gained attention mainly due to its low cost and abundance, and as highlighted before, for its ability to form stable and biocompatible films [131]. The CS, also known as manioc and tapioca, has also proven to be an excellent source of starch for electrochemical applications as will be detailed in the following works.

In 2017, Oliveira et al. [125] presented a new sensor architecture based on thin tapioca (TP) biofilm decorated with nitrogen-doped titanium dioxide nanoparticles in GCE for the detection of 17-β estradiol in tap water and samples of synthetic urine. The method used to produce starch dispersion is the same as used by Jodar et al. [41]. The formation of the TP film was revealed to be homogenous and when incorporated with N-TiO2, the presence of granules was observed throughout the film suggesting a good interaction between the starch and the nanoparticles. Therefore, the authors demonstrate that the electrochemical sensor produced has good repeatability and reproducibility with standard deviations of 5.3 and 5.1%, respectively.

Janegitz’s group designed a sensing platform based on a new composite from a thin film of CS and RGO which allowed sensitive and selective determination of dopamine and catechol in different samples [47]. Using this setup and by DPV, they could detect dopamine and catechol with LOD of the 0.07 μmol L−1 and 0.04 μmol L−1, respectively. The low LOD values and the excellent electrochemical behavior of the material, demonstrate the great potential of MS to be used in the proposed application, as a biopolymer film of easy manufacture and great stability. In addition, the work presents a series of interesting characterizations, including scanning electron and atomic force microscopy, ultraviolet–visible, Fourier transform infrared spectroscopies, and dynamic light scattering (DLS). The sensor production preparation scheme, as well as the characterizations performed, can be seen in Fig. 7.

Schematic illustration of Preparation of RGO-MS/GCE. A UV–Vis absorbance spectra of a RGO, b RGO-MS and c MS. B FT-IR spectra of a RGO, b RGO-MS and c MS. C AFM images, with the morphologic variation of a RGO, b RGO-MS and c MS. D Roughness bar graph, with calculated Ra (blue) and Rq (red) results. E Size distribution of a RGO, b RGO-MS, and c MS, determined by DLS. F SEM images of MS, the biopolymer film presented a homogeneous, uniform, and smooth surface. G RGO-MS, with the addition of RGO, the surface is no longer smooth, showing rough characteristics. H Present the lateral section of RGO-MS SEM images [47] (Reprinted from Orzari et al., 2018 with permission of Elsevier)

A MIP sensor modified with CS-Fe3O4 was designed by Mulyasuryani et al. [44] for simultaneous voltammetric detection of acetaminophen and caffeine. Starch dispersion was prepared and added CS to boiling water, then a few drops of 0.1 M NaOH solution were added to the pH value of 10. Following, 22 mL STPP was added along with 11 mL acetaminophen and 11 mL caffeine. MIP membranes with the best sensitivity were produced in a 2:2:1 mixing ratio. The performance of the sensor was also affected by the pH of the solution and the type of buffer solution used. In addition, the authors claim that CS/STPP: acetaminophen/caffeine in the MIP membrane mixture positively influences the sensitivity of the developed sensor.

Sensors for the detection of herbicides are a well-researched topic in the literature. Zambianco et al. [39] explored the manioc starch (MS) and nanodiamonds nanoparticles for fabricating a new architecture of an electrochemical sensor for diquat (DQ) determination in environmental samples, a non-selective contact herbicide. The procedure for modifying and producing the dispersion of MS is the same as that of Jodar et al.. According to the authors, the sensor developed showed an excellent response to diquat for determining it in rivers and samples of drinking water showing its efficiency as an environmental sensor. Furthermore, their investigations have shown that manioc starch film plays a key role in anchoring nanodiamonds to the surface of GCE.

In this regard, a thin biofilm composed of nanodiamonds and manioc starch has been proposed by Fernandes-Junior et al. [126]. The authors modified a GCE with the biofilm for the detection of the antibiotic tetracycline. The manioc starch dispersion was prepared, mixed with the nanodiamonds, and cast on a GCE surface. After 2 h, the solvent evaporated, and the biofilm was formed. The experimental procedure showing the complete steps involved can be seen in Fig. 7. The obtained thin film presented high homogeneity and stability, showing that the use of manioc starch is an interesting strategy.

Starch (Bio)sensors Based on Other Plant Material

Chin et al. [127], described a disposable electrochemical immunosensor with an application for the detection of the Japanese encephalitis virus (JEV). The developed method was based on the use of a screen-printed electrode (SPCE) modified with carbon nanoparticles that were prepared from sago starch nanoparticles and deposited on the SPCE working electrode whose surface was functionalized with 3-aminopropyl triethoxysilane. Then, the antibody of JEV was immobilized on the surfaces of the CNPs. The method of synthesizing CNPs were synthesized from preformed SS nanoparticles, where starch nanoparticles were prepared by adding dropwise, a starch solution to excess ethanol. SS nanoparticles formed were subsequently converted to carbon nanoparticles by dehydration with concentrated H2SO4. The authors observed an increase in electron transfer kinetics and the current intensity of the modified SPCE by 63% compared to an unmodified SPCE. This immunosensor strip was successfully applied to the detection of JEV in human serum samples. Furthermore, it represents a cost-effective alternative to conventional diagnostic tests for JEV according to the authors.

An elegant use for starch has been proposed by Kasturi et al. [128]. In their work, the starch obtained from jackfruit seeds was a precursor for preparing a nitrogen-inherited porous carbon material. For this, jackfruit seed starch powder was dried and stirred with 0.5 g of KOH overnight to obtain an activated carbon precursor, which was crushed and carbonized at different temperatures for 1 h under a constant flow of nitrogen. Figure 8 presents a schematic representation of the processes involved and the field emission scanning electron microscopy (FE-SEM) images. The carbon samples obtained were washed with double-distilled water, ethanol, and HCl. After drying, the solid was ground to a fine powder and sealed in an airtight container. The prepared NPC material was employed for the modification of a GCE, which was then applied toward the detection of dopamine with high selectivity and sensitivity. The inherited nitrogen atoms provided wettability for the adsorption of the molecule of dopamine, thus, an increase in the current and a very low onset potential were observed in the determination of dopamine.

Representative scheme of the preparation of activated carbon from AHS starch powder. FE-SEM images of a NPC-1, the structure with no porosity represents the inability of KOH to penetrate the surface of the carbon matrix, b NPC-2, which presents interconnected cylindrical pores due to penetration of KOH in the material network, c NPC-3, the presence of a higher number of aggregate structures without any porous morphology was observed due to the high carbonization temperature, and d the TEM image of NPC-2 [128] (Reprinted from Kasturi et al., 2021 with permission of Elsevier)

Conclusion and Perspectives

Natural polymers are very good alternatives that have been applied in several fields. Their relevant properties make them very attractive for replacing synthetic materials in various applications. Starch has been considered an interesting biopolymer in the development of sensors and biosensors because of its excellent properties.

Starch has been successfully used in electrode modification for the development of electrochemical sensors and biosensors. The physicochemical characteristics of starch have been exploited to produce membranes and thin films with a great electrochemical response. A wide variety of nanomaterials have been anchored to electrode surfaces using starch as a mediator and simple techniques such as drop-casting.

Thus, the properties of starches allow the introduction of chemical modifications which can collectively lead to major performance improvements. The chemically modified electrodes by starch are very recent and several mechanisms of interaction with materials used as modifiers still need to be elucidated to obtain more sensitive and reproducible sensors and biosensors.

In the future, three-dimensional structures and multi-imprinting of several templates could be performed by using starch, which can open the door to a fascinating range of fundamental applications. In this regard, the use of 3D printing technology can play an important role, enabling, besides the formation of surface films on 3D printed electrodes, the mixture of starches in the structure of thermoplastic filaments for fused deposition modeling printing as an example, attributing characteristics such as flexibility and elasticity to the developed sensors.

References

C. Liu, P. Luan, Q. Li, Z. Cheng, P. Xiang, D. Liu, Y. Hou, Y. Yang, H. Zhu, Biopolymers derived from trees as sustainable multifunctional materials: a review. Adv. Mater. (2020). https://doi.org/10.1002/adma.202170220

F. Zouaoui, S. Bourouina-Bacha, M. Bourouina, N. Jaffrezic-Renault, N. Zine, A. Errachid, Electrochemical sensors based on molecularly imprinted chitosan: a review. TrAC Trends Anal. Chem. 130, 115982 (2020)

J. Lukose, S. Chidangil, S.D. George, Optical technologies for the detection of viruses like COVID-19: progress and prospects. Biosens. Bioelectron. 178, 113004 (2021)

R.C. Sharp, E.S. Naser, K.P. Alcedo, A. Qasem, L.S. Abdelli, S.A. Naser, Development of multiplex PCR and multi-color fluorescent in situ hybridization (m-FISH) coupled protocol for detection and imaging of multi-pathogens involved in inflammatory bowel disease. Gut Pathog. 10(1), 51 (2018)

B.D. Ventura, M. Cennamo, A. Minopoli, R. Campanile, S.B. Censi, D. Terracciano, G. Portella, R. Velotta, Colorimetric test for fast detection of SARS-CoV-2 in nasal and throat swabs. ACS Sens. 5(10), 3043–3048 (2020)

T. Beduk, D. Beduk, J.I. de Oliveira Filho, F. Zihnioglu, C. Cicek, R. Sertoz, B. Arda, T. Goksel, K. Turhan, K.N. Salama, S. Timur, Rapid point-of-care COVID-19 diagnosis with a gold-nanoarchitecture-assisted laser-scribed graphene biosensor. Anal. Chem. 93(24), 8585–8594 (2021)

J.S. Stefano, L.R. Guterres e Silva, R.G. Rocha, L.C. Brazaca, E.M. Richter, R.A. Abarza Muñoz, B.C. Janegitz, New conductive filament ready-to-use for 3D-printing electrochemical (bio)sensors: towards the detection of SARS-CoV-2. Anal. Chim. Acta 1191, 339372 (2022)

J.S. Stefano, L.O. Orzari, H.A. Silva-Neto, V.N. de Ataíde, L.F. Mendes, W.K.T. Coltro, T.R. Longo Cesar Paixão, B.C. Janegitz, Different approaches for fabrication of low-cost electrochemical sensors. Curr. Opin. Electrochem. 32, 100893 (2022)

L.C. Brazaca, P.L. dos Santos, P.R. de Oliveira, D.P. Rocha, J.S. Stefano, C. Kalinke, R.A. Abarza-Muñoz, J.A. Bonacin, B.C. Janegitz, E. Carrilho, Biosensing strategies for the electrochemical detection of viruses and viral diseases—a review. Anal. Chim. Acta 1159, 338384 (2021)

Q. Song, X. Sun, Z. Dai, Y. Gao, X. Gong, B. Zhou, J. Wu, W. Wen, Point-of-care testing detection methods for COVID-19. Lab Chip 21(9), 1634–1660 (2021)

J.S. Stefano, C. Kalinke, R.G. da Rocha, D.P. Rocha, V.A.O.P. da Silva, J.A. Bonacin, L. Angnes, E.M. Richter, B.C. Janegitz, R.A.A. Muñoz, electrochemical (bio)sensors enabled by fused deposition modeling-based 3D printing: a guide to selecting designs. Print. Param. Post-Treat. Protoc., Anal. Chem. 94(17), 6417–6429 (2022)

H. Teymourian, A. Barfidokht, J. Wang, Electrochemical glucose sensors in diabetes management: an updated review (2010–2020). Chem. Soc. Rev. 49(21), 7671–7709 (2020)

M.R. de Eguilaz, L.R. Cumba, R.J. Forster, Electrochemical detection of viruses and antibodies: a mini review. Electrochem. Commun. 116, 106762 (2020)

B.C. Janegitz, T.A. Silva, A. Wong, L. Ribovski, F.C. Vicentini, M.D.P. Taboada Sotomayor, O. Fatibello-Filho, The application of graphene for in vitro and in vivo electrochemical biosensing. Biosens. Bioelectron. 89(Pt 1), 224–233 (2017)

F.C. Vicentini, A.E. Ravanini, L.C.S. Figueiredo-Filho, J. Iniesta, C.E. Banks, O. Fatibello-Filho, Imparting improvements in electrochemical sensors: evaluation of different carbon blacks that give rise to significant improvement in the performance of electroanalytical sensing platforms. Electrochim. Acta 157, 125–133 (2015)

P.A. Raymundo-Pereira, A.M. Campos, F.C. Vicentini, B.C. Janegitz, C.D. Mendonça, L.N. Furini, N.V. Boas, M.L. Calegaro, C.J.L. Constantino, S.A.S. Machado, O.N. Oliveira, Sensitive detection of estriol hormone in creek water using a sensor platform based on carbon black and silver nanoparticles. Talanta 174, 652–659 (2017)

F.C. Vicentini, T.A. Silva, A. Pellatieri, B.C. Janegitz, O. Fatibello-Filho, R.C. Faria, Pb(II) determination in natural water using a carbon nanotubes paste electrode modified with crosslinked chitosan. Microchem. J. 116, 191–196 (2014)

W. Liang, H. Ren, Y. Li, H. Qiu, B.-C. Ye, A robust electrochemical sensing based on bimetallic metal-organic framework mediated Mo2C for simultaneous determination of acetaminophen and isoniazid. Anal. Chim. Acta 1136, 99–105 (2020)

Y. Li, J. Liu, Y. Zhang, M. Gu, D. Wang, Y.-Y. Dang, B.-C. Ye, Y. Li, A robust electrochemical sensing platform using carbon paste electrode modified with molecularly imprinted microsphere and its application on methyl parathion detection. Biosens. Bioelectron. 106, 71–77 (2018)

R.W. Murray, Chemically modified electrodes. Acc. Chem. Res. 13(5), 135–141 (1980)

P.S. Adarakatti, S.K. Kempahanumakkagari, Modified electrodes for sensing. Electrochemistry 15, 58–95 (2019)

R.L. McCreery, K.K. Cline, C.A. McDermott, M.T. McDermott, Control of reactivity at carbon electrode surfaces. Colloids Surf., A 93, 211–219 (1994)

X. Wang, L. Huang, C. Zhang, Y. Deng, P. Xie, L. Liu, J. Cheng, Research advances in chemical modifications of starch for hydrophobicity and its applications: a review. Carbohydr. Polym. 240, 116292 (2020)

S.W. Cui, Food Carbohydrates: Chemistry, Physical Properties, and Applications (CRC Press, Boca Raton, 2005)

S.C. Alcázar-Alay, M.A.A. Meireles, Physicochemical properties, modifications and applications of starches from different botanical sources. J. Food Sci. Technol. 35, 215–236 (2015)

M. Ziegler-Borowska, K. Wegrzynowska-Drzymalska, D. Chelminiak-Dudkiewicz, J. Kowalonek, H. Kaczmarek, Photochemical reactions in dialdehyde starch. Molecules 23(12), 3358 (2018)

M.S. Madihah, A.B. Ariff, K.M. Sahaid, A.A. Suraini, M.I.A. Karim, Direct fermentation of gelatinized sago starch to acetone–butanol–ethanol by Clostridium acetobutylicum. World J. Microbiol. Biotechnol. 17(6), 567–576 (2001)

N. Çankaya, Synthesis of graft copolymers onto starch and its semiconducting properties. Results Phys. 6, 538–542 (2016)

B.M. Simões, C. Cagnin, F. Yamashita, J.B. Olivato, P.S. Garcia, S.M. de Oliveira, M.V. Eiras Grossmann, Citric acid as crosslinking agent in starch/xanthan gum hydrogels produced by extrusion and thermopressing. LWT 125, 108950 (2020)

Z.M. González-Parada, E.E. Pérez-Sira, Physicochemical and functional evaluation of pregelatinized and microwaved cassava (Manihot esculenta Cranz) starches. Acta Cient. Venez. 54(2), 127–137 (2003)

C. Loisel, Z. Maache-Rezzoug, C. Esneault, J.L. Doublier, Effect of hydrothermal treatment on the physical and rheological properties of maize starches. J. Food Eng. 73(1), 45–54 (2006)

J. Szymońska, F. Krok, E. Komorowska-Czepirska, K. Rębilas, Modification of granular potato starch by multiple deep-freezing and thawing. Carbohyd. Polym. 52(1), 1–10 (2003)

Z.-Q. Huang, J.-P. Lu, X.-H. Li, Z.-F. Tong, Effect of mechanical activation on physico-chemical properties and structure of cassava starch. Carbohyd. Polym. 68(1), 128–135 (2007)

L.M. Hansen, R.C. Hoseney, J.M. Faubion, Oscillatory probe rheometry as a tool for determining the rheological properties of starch-water systems 1. J. Texture Stud. 21(2), 213–224 (1990)

R.P. Ellis, M.P. Cochrane, M.F.B. Dale, C.M. Duffus, A. Lynn, I.M. Morrison, R.D.M. Prentice, J.S. Swanston, S.A. Tiller, Starch production and industrial use. J. Sci. Food Agric. 77(3), 289–311 (1998)

M. Bhattacharjee, S. Middya, P. Escobedo, J. Chaudhuri, D. Bandyopadhyay, R. Dahiya, Microdroplet based disposable sensor patch for detection of alpha-amylase in human blood serum. Biosens. Bioelectron. 165, 112333 (2020)

G. Khachatryan, K. Khachatryan, Starch based nanocomposites as sensors for heavy metals: detection of Cu2+ and Pb2+ ions. Int. Agrophys. 33(1), 121–126 (2019)

P.R.S. Teixeira, A. Teixeira, E.A.O. Farias, E.C. da Silva Filho, H.N. da Cunha, J.R. Dos Santos Junior, L.C.C. Nunes, H.R.S. Lima, C. Eiras, Development of a low-cost electrochemical sensor based on babassu mesocarp (Orbignya phalerata) immobilized on a flexible gold electrode for applications in sensors for 5-fluorouracil chemotherapeutics. Anal. Bioanal. Chem. 411(3), 659–667 (2019)

N.A. Zambianco, T.A. Silva, H. Zanin, O. Fatibello-Filho, B.C. Janegitz, Novel electrochemical sensor based on nanodiamonds and manioc starch for detection of diquat in environmental samples. Diamond Relat. Mater. 98, 107512 (2019)

K.P. Delgado, P.A. Raymundo-Pereira, A.M. Campos, O.N. Oliveira, B.C. Janegitz, Ultralow cost electrochemical sensor made of potato starch and carbon black nanoballs to detect tetracycline in waters and milk. Electroanalysis 30(9), 2153–2159 (2018)

L.V. Jodar, F.A. Santos, V. Zucolotto, B.C. Janegitz, Electrochemical sensor for estriol hormone detection in biological and environmental samples. J. Solid State Electrochem. 22(5), 1431–1438 (2018)

J.R. Camargo, M. Baccarin, P.A. Raymundo-Pereira, A.M. Campos, G.G. Oliveira, O. Fatibello-Filho, O.N. Oliveira Jr., B.C. Janegitz, Electrochemical biosensor made with tyrosinase immobilized in a matrix of nanodiamonds and potato starch for detecting phenolic compounds. Anal Chim Acta 1034, 137–143 (2018)

X. Liu, Z. Pan, Z. Dong, Y. Lu, Q. Sun, T. Wu, N. Bao, H. He, H. Gu, Amperometric oxygen biosensor based on hemoglobin encapsulated in nanosized grafted starch particles. Microchim. Acta 183(1), 353–359 (2015)

A. Mulyasuryani, R. Tjahjanto, R.A. Andawiyah, Simultaneous voltammetric detection of acetaminophen and caffeine base on cassava starch—Fe3O4 nanoparticles modified glassy carbon electrode. Chemosensors 7(4), 49 (2019)

Q. Lin, Electrochemical determination of Hg(II) ions based on biosynthesized spherical activated carbon from potato starch. Int. J. Electrochem. Sci. (2017) 2232–2241

S.M. Azab, A comprehensive structural comparison between cellulose and starch polymers functionalized cobalt nanoparticles sensors for the nanomolar detection of paracetamol. J. Electroanal. Chem. 840, 319–327 (2019)

L.O. Orzari, F.A. Santos, B.C. Janegitz, Manioc starch thin film as support of reduced graphene oxide: a novel architecture for electrochemical sensors. J. Electroanal. Chem. 823, 350–358 (2018)

V. Gautam, K.P. Singh, V.L. Yadav, Polyaniline/multiwall carbon nanotubes/starch nanocomposite material and hemoglobin modified carbon paste electrode for hydrogen peroxide and glucose biosensing. Int J Biol Macromol 111, 1124–1132 (2018)

M. Mahanthappa, S. Yellappa, N. Kottam, C. Srinivasa-Rao-Vusa, Sensitive determination of caffeine by copper sulphide nanoparticles modified carbon paste electrode. Sens. Actu. A 248, 104–113 (2016)

J. Tian, J. Huang, Y. Zhao, S. Zhao, Electrochemical immunosensor for prostate-specific antigen using a glassy carbon electrode modified with a nanocomposite containing gold nanoparticles supported with starch-functionalized multi-walled carbon nanotubes. Microchim. Acta 178(1–2), 81–88 (2012)

X. Huacui, Z. Li, H. Liu, T. Chen, H. Zhou, W. Huang, Green flexible electronics based on starch. NPJ Flexible Electron. (2022). https://doi.org/10.1038/s41528-022-00147-x

E. Wawrzynek, C. Baumbauer, A.C. Arias, Characterization and comparison of biodegradable printed capacitive humidity sensors. Sensors 21(19), 6557 (2021)

Y.-F. Chen, L. Kaur, J. Singh, Chapter 7: chemical modification of starch, in Starch in Food (Second Edition). ed. by M. Sjöö, L. Nilsson (Woodhead Publishing, Cambridge, 2018), pp.283–321

R.L. Whistler, J.N. BeMiller, E.F. Paschall, Starch: Chemistry and Technology (Elsevier Science, Amsterdam, 2012)

Z. Sui, X. Kong, Physical Modifications of Starch (Springer, Singapore, 2018)

Y.X. Xu, Y. Dzenis, M.A. Hanna, Water solubility, thermal characteristics and biodegradability of extruded starch acetate foams. Ind. Crops Prod. 21(3), 361–368 (2005)

K. Liu, Y. Zu, C. Chi, B. Gu, L. Chen, X. Li, Modulation of the digestibility and multi-scale structure of cassava starch by controlling the cassava growth period. Int. J. Biol. Macromol. 120(Pt A), 346–353 (2018)

J.N. BeMiller, R.L. Whistler, Starch: Chemistry and Technology (Elsevier Science, Amsterdam, 2009)

A. Kaur, N. Singh, R. Ezekiel, H.S. Guraya, Physicochemical, thermal and pasting properties of starches separated from different potato cultivars grown at different locations. Food Chem. 101(2), 643–651 (2007)

Y. Fan, F. Picchioni, Modification of starch: a review on the application of “green” solvents and controlled functionalization. Carbohydr Polym 241, 116350 (2020)

S. Pérez, E. Bertoft, The molecular structures of starch components and their contribution to the architecture of starch granules: a comprehensive review. Starch - Stärke 62(8), 389–420 (2010)

J. Jane, Y.Y. Chen, L.F. Lee, A.E. McPherson, K.S. Wong, M. Radosavljevic, T. Kasemsuwan, Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of strach. Cereal Chem. 76(5), 629–637 (1999)

F.E. Ortega-Ojeda, H. Larsson, A.-C. Eliasson, Gel formation in mixtures of high amylopectin potato starch and potato starch. Carbohyd. Polym. 56(4), 505–514 (2004)

F.E. Ortega-Ojeda, H. Larsson, A.-C. Eliasson, Gel formation in mixtures of amylose and high amylopectin potato starch. Carbohyd. Polym. 57(1), 55–66 (2004)

S. Shukla, S.S. Pandey, M. Chandra, A. Pandey, N. Bharti, D. Barnawal, C.S. Chanotiya, S. Tandon, M.P. Darokar, A. Kalra, Application of essential oils as a natural and alternate method for inhibiting and inducing the sprouting of potato tubers. Food Chem. 284, 171–179 (2019)

D.H. Kringel, S.L.M. El-Halal, E.R. Zavareze, A.R.G. Dias, Methods for the extraction of roots, tubers, pulses, pseudocereals, and other unconventional starches sources: a review. Starch Stärke 72(11–12), 1900234 (2020)

A.B. Altemimi, Extraction and optimization of potato starch and its application as a stabilizer in yogurt manufacturing. Foods 7(2), 14 (2018)

R. Liu, W. Sun, Y. Zhang, Z. Huang, H. Hu, M. Zhao, Preparation of starch dough using damaged cassava starch induced by mechanical activation to develop staple foods: application in crackers. Food Chem. 271, 284–290 (2019)

I.M. Demiate, V. Kotovicz, Cassava starch in the Brazilian food industry. J. Food Sci. Technol. 31, 388–397 (2011)

J.J.M. Swinkels, Composition and properties of commercial native starches. Starch 37(1), 1–5 (1985)

F. Zhu, Composition, structure, physicochemical properties, and modifications of cassava starch. Carbohydr. Polym. 122, 456–480 (2015)

S. Hizukuri, S. Tabata, Kagoshima, Z. Nikuni, Studies on starch phosphate part 1. Estimation of glucose-6-phosphate residues in starch and the presence of other bound phosphate(s). Starch, 22(10) (1970) 338–343.

T.J. Schoch, Non-carbohydrate substances in the cereal starches. J. Am. Chem. Soc. 64(12), 2954–2956 (1942)

H.F. Zobel, Molecules to granules: a comprehensive starch review. Starch 40(2), 44–50 (1988)

M.-H. Chen, C.J. Bergman, Method for determining the amylose content, molecular weights, and weight- and molar-based distributions of degree of polymerization of amylose and fine-structure of amylopectin. Carbohyd. Polym. 69(3), 562–578 (2007)

M.E. Schimpf, K. Caldwell, J.C. Giddings, Field-Flow Fractionation Handbook (Wiley, New York, 2000)

D.R. Lineback, The starch granule organization and properties, 1984.

A.C. Eliasson, Carbohydrates in Food (CRC Press/Taylor & Francis, Boca Raton, 2017)

P. Chinachoti, M.P. Steinberg, Crystallinity of waxy maize starch as influenced by ambient temperature absorption and desorption, sucrose content water activity. Food Sci. 51(4), 997–1000 (1986)

E. Svensson, A.-C. Eliasson, Crystalline changes in native wheat and potato starches at intermediate water levels during gelatinization. Carbohyd. Polym. 26(3), 171–176 (1995)

S. Pérez, P.M. Baldwin, D.J. Gallant, Chapter 5 - Structural Features of Starch Granules I. In Starch Chemistry and Technology (third edition), ed. by J. BeMiller, R. Whistler (Food Science and Technology, 2009), pp. 149–192

H.O. Egharevba, Chemical properties of starch and its application in the food industry, in Chemical Properties of Starch. ed. by M. Emeje (IntechOpen, London, 2019)

S. Park, Y.-R. Kim, Clean label starch: production, physicochemical characteristics, and industrial applications. Food Sci. Biotechnol. 30(1), 1–17 (2021)

A.O. Ashogbon, E.T. Akintayo, Recent trend in the physical and chemical modification of starches from different botanical sources: a review. Starch Stärke 66(1–2), 41–57 (2014)

S.I. Shin, H.J. Kim, H.J. Ha, S.H. Lee, T.W. Moon, Effect of hydrothermal treatment on formation and structural characteristics of slowly digestible non-pasted granular sweet potato starch. Starch Stärke 57(9), 421–430 (2005)

P.A.M. Steeneken, A.J.J. Woortman, Superheated starch: a novel approach towards spreadable particle gels. Food Hydrocoll. 23(2), 394–405 (2009)

Z. Han, X.-A. Zeng, B.-S. Zhang, S.-J. Yu, Effects of pulsed electric fields (PEF) treatment on the properties of corn starch. J. Food Eng. 93(3), 318–323 (2009)

M.E. Gomes, A.S. Ribeiro, P.B. Malafaya, R.L. Reis, A.M. Cunha, A new approach based on injection moulding to produce biodegradable starch-based polymeric scaffolds: morphology, mechanical and degradation behaviour. Biomaterials 22(9), 883–889 (2001)

D. Ackar, J. Babic, A. Jozinovic, B. Milicevic, S. Jokic, R. Milicevic, M. Rajic, D. Subaric, Starch modification by organic acids and their derivatives: a review. Molecules 20(10), 19554–19570 (2015)

I. Gholamali, S.N. Hosseini, E. Alipour, M. Yadollahi, Preparation and characterization of oxidized starch/CuO nanocomposite hydrogels applicable in a drug delivery system. Starch Stärke 71(3–4), 1800118 (2019)

F.D.S. Larotonda, K.S. Matsui, S.S. Paes, J.B. Laurindo, Impregnation of kraft paper with cassava-starch acetate—analysis of the tensile strength, water absorption and water vapor permeability. Starch Stärke 55(11), 504–510 (2003)

K. Okuda, K. Hirota, T. Mizutani, Y. Aoyama, Co-precipitation of tapioca starch and hydroxyapatite. Effects of phosphorylation of starch on mechanical properties of the composites. Results Mater. 3, 100035 (2019)

L. do Val Siqueira, C.I.L.F. Arias, B.C. Maniglia, C.C. Tadini, Starch-based biodegradable plastics: methods of production, challenges and future perspectives. Curr. Opin. Food Sci. 38, 122–130 (2021)

H. Yin, P. Zheng, E. Zhang, J. Rao, Q. Lin, M. Fan, Z. Zhu, Q. Zeng, N. Chen, Improved wet shear strength in eco-friendly starch-cellulosic adhesives for woody composites. Carbohyd. Polym. 250, 116884 (2020)

S. Iqbal, P. Wu, T.V. Kirk, X.D. Chen, Amylose content modulates maize starch hydrolysis, rheology, and microstructure during simulated gastrointestinal digestion. Food Hydrocolloids 110, 106171 (2021)

G.G. Maher, Alkali gelatinization of starches. Starch - Stärke 35(7), 226–234 (1983)

O. Moreno, J. Cárdenas, L. Atarés, A. Chiralt, Influence of starch oxidation on the functionality of starch-gelatin based active films. Carbohyd. Polym. 178, 147–158 (2017)

M. Łabanowska, M. Kurdziel, E. Bidzińska, A. Wesełucha-Birczyńska, D. Pawcenis, T. Łojewski, T. Fortuna, S. Pietrzyk, I. Przetaczek-Rożnowska, Influence of starch oxidation and phosphorylation on thermal generation of carbohydrate radicals studied by electron paramagnetic resonance. Starch Stärke 65(9–10), 782–790 (2013)

O.S. Lawal, Succinylated Dioscorea cayenensis starch: effect of reaction parameters and characterisation. Starch Stärke 64(2), 145–156 (2012)

A.I. Olagunju, O.S. Omoba, V.N. Enujiugha, R.A. Wiens, K.M. Gough, R.E. Aluko, Influence of acetylation on physicochemical and morphological characteristics of pigeon pea starch. Food Hydrocolloids 100, 105424 (2020)

C. Perera, H. Hoover, The reactivity of porcine pancreatic alpha-amylase towards native, defatted and heat-moisture treated potato starches before and after hydroxypropylation. Starch Stärke 50(5), 206–213 (1998)

A. Hebeish, M.I. Khalil, A. Hashem, Carboxymethylation of starch and oxidized starches. Starch Stärke 42(5), 185–191 (1990)

R. Wongsagonsup, S. Shobsngob, B. Oonkhanond, S. Varavinit, Zeta potential (ζ) and pasting properties of phosphorylated or crosslinked rice starches. Starch Stärke 57(1), 32–37 (2005)

H. Zhong, X. Kong, S. Chen, B.P. Grady, Z. Qiu, Preparation, characterization and filtration control properties of crosslinked starch nanospheres in water-based drilling fluids. J. Mol. Liq. 325, 115221 (2021)

Q.G. Mark, H. Xinzhong, W. Changlu, A. Lianzhong, Polysaccharides: structure and solubility (2017).

O.S. Lawal, Succinyl and acetyl starch derivatives of a hybrid maize: physicochemical characteristics and retrogradation properties monitored by differential scanning calorimetry. Carbohyd. Res. 339(16), 2673–2682 (2004)

T. Komiya, S. Nara, Changes in crystallinity and gelatinization phenomena of potato starch by acid treatment. Starch Stärke 38(1), 9–13 (1986)

M. Wootton, P. Ho, Alkali gelatinisation of wheat starch. Starch Stärke 41(7), 261–265 (1989)

J. Singh, L. Kaur, O.J. McCarthy, Factors influencing the physico-chemical, morphological, thermal and rheological properties of some chemically modified starches for food applications—a review. Food Hydrocoll. 21(1), 1–22 (2007)

M.H. Gomez, J.M. Aguilera, A physicochemical model for extrusion of corn starch. Food Sci. 49(1), 40–43 (1984)

C. Maria Teresa Pedrosa Silva, Physical and/or Chemical Modifications of Starch by Thermoplastic Extrusion. (2012).

N. Zehra, T.M. Ali, A. Hasnain, Combined effects of hydroxypropylation and alcoholic alkaline treatment on structural, functional and rheological characteristics of sorghum and corn starches. Int. J. Biol. Macromol. 174, 22–31 (2021)

D. Gałkowska, L. Juszczak, Effects of amino acids on gelatinization, pasting and rheological properties of modified potato starches. Food Hydrocoll. 92, 143–154 (2019)

C.-N. Wu, H.-M. Lai, Novel pH-responsive granules with tunable volumes from oxidized corn starches. Carbohyd. Polym. 208, 201–212 (2019)

P. Van Hung, N. Morita, Dough properties and bread quality of flours supplemented with cross-linked cornstarches. Food Res. Int. 37(5), 461–467 (2004)

S. Simsek, M. Ovando-Martinez, A. Marefati, M. Sjӧӧ, M. Rayner, Chemical composition, digestibility and emulsification properties of octenyl succinic esters of various starches. Food Res. Int. 75, 41–49 (2015)

P.K. Kalambate, Z. Rao, Dhanjai, J. Wu, Y. Shen, R. Boddula, Y. Huang, Electrochemical (bio) sensors go green. Biosens. Bioelectron. 163 (2020) 112270.

V. Gautam, K.P. Singh, V.L. Yadav, Polyaniline/MWCNTs/starch modified carbon paste electrode for non-enzymatic detection of cholesterol: application to real sample (cow milk). Anal. Bioanal. Chem. 410(8), 2173–2181 (2018)

J. Srivastava, A. Kushwaha, M. Singh, Imprinted graphene-starch nanocomposite matrix-anchored EQCM platform for highly selective sensing of epinephrine. NANO 13(11), 1850131 (2018)

R. Jagadish, S. Yellappa, M. Mahanthappa, K.B. Chandrasekhar, Zinc oxide nanoparticle-modified glassy carbon electrode as a highly sensitive electrochemical sensor for the detection of caffeine. J. Chin. Chem. Soc. 64(7), 813–821 (2017)

J. Srivastava, A. Kushwaha, M. Srivastava, A. Srivastava, M. Singh, Glycoprotein imprinted RGO-starch nanocomposite modified EQCM sensor for sensitive and specific detection of transferrin. J. Electroanal. Chem. 835, 169–177 (2019)

J. Zou, X.-Q. Chen, G.-Q. Zhao, X.-Y. Jiang, F.-P. Jiao, J.-G.J.T. Yu, A novel electrochemical chiral interface based on the synergistic effect of polysaccharides for the recognition of tyrosine enantiomers. Talanta 195, 628–637 (2019)

J. Ramu, M. Mahanthappa, S. Yellappa, K.B. Chandrasekhar, γ-Fe2O3 nanoparticles modified glassy carbon electrode for the sensitive detection of folic acid. Mater. Res. Express 6(10), 105070 (2019)

R.A. Sayka, T.C. Rozada, D. Lima, C.A. Pessôa, A.G. Viana, B.C.J.S.S. Fiorin, Synthesis and spectroscopic characterization of an unusual succinylated starch applied to carbon paste electrodes. Strach 72(3–4), 1900056 (2020)

G.C. Mauruto de Oliveira, E.P. de Palma, M.H. Kunita, R. Antigo-Medeiros, R. de Matos, K.R. Francisco, B.C. Janegitz, Tapioca biofilm containing nitrogen-doped titanium dioxide nanoparticles for electrochemical detection of 17-β estradiol. Electroanalysis 29(11), 2638–2645 (2017)

W.S. Fernandes-Junior, L.F. Zaccarin, G.G. Oliveira, P.R. de Oliveira, C. Kalinke, J.A. Bonacin, J. Prakash, B.C. Janegitz, Electrochemical sensor based on nanodiamonds and manioc starch for detection of tetracycline. J. Sens. 2021, 6622612 (2021)

S.F. Chin, L.S. Lim, S.C. Pang, M.S.H. Sum, D. Perera, Carbon nanoparticle modified screen printed carbon electrode as a disposable electrochemical immunosensor strip for the detection of Japanese encephalitis virus. Microchim. Acta 184(2), 491–497 (2016)

P.R. Kasturi, T.K. Aparna, A.L. Arokiyanathan, S. Lakshmipathi, R. Sivasubramanian, Y.S. Lee, R.C. Selvan, Synthesis of metal-free nitrogen-enriched porous carbon and its electrochemical sensing behavior for the highly sensitive detection of dopamine: both experimental and theoretical investigation. Mater. Chem. Phys. 260, 124094 (2021)

H.E. Grommers, D.A. van der Krogt, Chapter 11 - potato starch: production, modifications and uses, in Starch (Third Edition). ed. by J. BeMiller, R. Whistler (Academic Press, San Diego, 2009), pp. 511–539

J.H. Han, Innovations in Food Packaging (Elsevier Science, Amsterdam, 2005)

A. Podshivalov, M. Zakharova, E. Glazacheva, M. Uspenskaya, Gelatin/potato starch edible biocomposite films: correlation between morphology and physical properties. Carbohydr. Polym. 157, 1162–1172 (2017)

Q.V. Vuong, Utilisation of Bioactive Compounds from Agricultural and Food Waste (CRC Press, Taylor & Francis Group, Boca Raton, 2017)

Acknowledgements

The authors acknowledge financial support from Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) (2013/22127-, 2022/06145-0 and 2017/21097-3), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (303338/2019-9) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) – Finance Code 001, 88887.504861/2020-00 and 88887.517992/2020-00.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vicentini, F.C., Silva, L.R.G., Stefano, J.S. et al. Starch-Based Electrochemical Sensors and Biosensors: A Review. Biomedical Materials & Devices 1, 319–338 (2023). https://doi.org/10.1007/s44174-022-00012-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44174-022-00012-5