Abstract

Tomato peel by-products contain high levels of lycopene, which has traditionally been extracted using organic solvents. This research focuses on the optimisation of a sustainable method to obtain a lycopene-rich extract using the biodegradable anionic surfactant sodium dodecyl sulphate (SDS). A Plackett–Burman experimental design was used to investigate the effect of seven factors on the extraction of carotenoids from tomato peels using sodium dodecyl sulphate (SDS volume and concentration, homogenisation intensity and time, sonication phase, extraction time and ultracentrifugation intensity). Based on the responses of total carotenoid extraction, the SDS volume, the use of ultrasound and the extraction time significantly influenced the extraction yield and were selected for optimisation using a Box–Wilson experimental design. The final green extraction protocol (1 g sample + 11.9 ml SDS 0.3%, homogenisation at 13,500 rpm for 2 min, ultrasound phase, agitation for 8.2 h and ultracentrifugation) was selected after quantification of total carotenoids by UV–VIS and HPLC-DAD. Finally, we used nuclear magnetic resonance to demonstrate a high lycopene purity in the carotenoid extract obtained. Furthermore, using transmission electron microscopy, we observed the presence of intact chromoplasts in the extract, protecting the carotenoids from the exposure to external agents. Thus, this work reports an optimised method for the sustainable extraction of carotenoids and demonstrates the viability of the degradable solvent SDS for the extraction of liposoluble bioactive compounds, like carotenoids and mainly lycopene. The lycopene extract could be used for the technological and nutritional enrichment of new foods and/or the design of nutraceuticals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carotenoids are the most efficient singlet oxygen (1O2) quenchers found in nature (Kruk & Szymańska, 2021); specifically, lycopene and β-carotene have high antioxidant capacity by quenching the singlet oxygen rate and trapping peroxyl radicals (Di Mascio et al., 1990). The beneficial effects of carotenoids on human health have been widely described, not only due to their antioxidant activity, but also due to their ability to improve gap junctional intercellular communication and to modulate gene expression and metabolic pathways (Meléndez‐Martínez, 2019). Carotenoids cannot be synthesised by the human body, so they are ingested in the daily diet, mainly through the consumption of coloured plant foods, where they are accumulated in the chromoplasts. Hence, there is a general interest in promoting their consumption as part of a healthy diet. Particularly, lycopene, the predominant carotenoid in tomato, exerts a hypocholesterolaemic effect (Navarro-González et al., 2014), and a beneficial effect in the prevention of cardiovascular and neurodegenerative diseases and several types of cancer (Saini et al., 2020).

The tomato processing market produced 39.185 million kilos worldwide in 2021, being one of the most consumed fruits in the world. In addition, Spain was the fourth largest producer with 3.185 million kilos (Ctaex, 2022). The tomato industry generates waste about 4% of fresh processed tomatoes, in the form of peels, seeds or pulp, which are an interesting source of lycopene and β-carotene (Méndez-Carmona et al., 2022; Navarro-González et al., 2011). By reusing the solid waste, a carotenoid-rich extract can be obtained from a natural source, providing a value-added ingredient that can respond to the increasing demand for functional foods, nutraceuticals, active packaging and cosmetics, containing mainly lycopene but also β-carotene (Madia et al., 2021; Messinese et al., 2023).

For carotenoid extraction, organic solvents have been used in conventional methods, but such extraction processes have long exposure time, generation of hazardous volatile organic compounds, residual amounts of the solvents and a negative impact on health, safety and environment (Madia et al., 2021; Zuorro et al., 2013). The lipophilic nature of carotenoids makes them difficult to extract using environmentally friendly methods. For example, supercritical CO2 extraction has been shown to be an interesting method to eliminate the use of organic solvents, but this technique requires the addition of a co-solvent (such as ethanol or vegetable oils) to increase the solubility of the carotenoids (Pereira & Meireles, 2010) and high investment costs for the industry (Kehili et al., 2017). Other green extraction technologies would be microwave-assisted extraction (MAE) (Nonglait & Gokhale, 2023) or high-pressure extraction (HPE) (López-Cruz et al., 2023), and although both methods have low solvent requirements, MAE would cause an increase in matrix temperature which may lead to pigment degradation, while HPE causes severe damage to plant cells and may expose carotenoids to environmental factors.

For this reason, in the last decade, there is an interest in applying the principles of green chemistry to the extraction of carotenoids using processes that are economically and environmentally sustainable, such as the microemulsion technique using biodegradable surfactants. Sodium dodecyl sulphate (SDS) is a biodegradable anionic surfactant that is used in the pharmaceutical and cosmetic industries. In addition, the FDA recognises SDS as a safe substance (21 CFR 172.822, GRAS) and can be used as an emulsifier additive in some food products (FDA, 2023). SDS forms micelles when dissolved in water and incorporates cell chromoplasts into the micelles, thereby extracting carotenoids into the chromoplasts, and potentially preventing their isomerisation and degradation by oxidation. Several factors (such as temperature, chemical reactions, heat treatment and exposure to light) cause isomerisation from all-E carotenoids to Z geometric isomers. Although isomerisation has been related with improved bioavailability and bioactivity of lycopene, Z-isomers are more easily oxidised than all-E ones, which isomerisation contributes to the lycopene instability leading to the oxidation cleavage compounds (apo-lycopenals and apocarotendials) (Meléndez-Martínez et al., 2004; Schieber & Carle, 2005).

In addition to the microemulsion procedure, the ultrasound-assisted extraction has been reported to increase the extraction of carotenoids in oil due to the breakage of cross-links between these compounds and other macromolecules, thus its effortless integration into established processes and notably higher efficiency distinguish it from other eco-friendly alternatives (Gouda et al., 2021). Although some studies have proposed SDS as solvent for carotenoids extraction from different plant foods (such as watermelon, papaya and tomato) and brown seaweeds, these methods either add the organic solvent acetonitrile to precipitate and obtain the carotenoids extract (Fish, 2006, 2007) or only solubilised the lycopene in the SDS, without recovery of carotenoids from the microemulsion (Vieira et al., 2018).

With the aim of optimising the analytical conditions for the extraction of carotenoids with SDS from tomato by-products, these conditions were optimised by two consecutive steps (Joglekar & May, 1987). The first step was to identify how many of the apparent critical factors (ACFs) selected from scientific literature and our own experience were influencing factors (IFs) for the analytical procedure using the Plackett–Burman experimental design 2(k−p), which is a very useful tool for obtaining the best results in terms of extraction yield (Box & Hunter, 1961; Robinson, 2000). The second step was to find the best combinations and levels of the IFs to obtain the most sensitive and efficient extraction method. To do that, a Box–Wilson experimental design was used, as the result of superimposing a factorial at two levels (2N) on a star design (2N+1) (Araujo & Brereton, 1996; Box & Hunter, 1961). Finally, in order to describe the relationship between IFs and responses (extracted carotenoids), we used the response surface methodology (RSM), which comprises a set of techniques used in the empirical study of relationships between one or more responses and a group of input factors, to locate the highest response value (Cornell, 1990; Yolmeh & Jafari, 2017). Once the microemulsion method for carotenoid extraction with SDS from tomato peels was optimised, we examined the lycopene purity of the extract obtained by ultracentrifugation, as an alternative method to the use of organic solvents, using nuclear magnetic resonance (NMR). Furthermore, we used transmission electron microscopy (TEM) to observe the presence of intact chromoplasts in the extract, protecting the carotenoids from the exposure to external agents.

Material and Methods

Reagents and Chemicals

Carotenoid standards (lycopene and β-carotene) were purchased from LGC Standard (Barcelona, Spain). Sodium dodecyl sulphate (SDS) was obtained from Sigma-Aldrich (Steinheim, Germany). Ethanol, methanol (MeOH), hexane, tert-butyl methyl ether (TBME) and acetonitrile (ACN) of HPLC grade, as well as acetone, were purchased from Honeywell (Seelze, Germany).

Plant Material

The samples used in the present study were raw tomato peels of different cultivars obtained as a by-product from a local vegetable processing industry (Murcia, Spain). After collection, the samples were immediately transported to the laboratory, where they were stored in opaque plastic bottles at −80 °C until analysis. Before starting the optimisation experiment, the physico-chemical characteristics of the sample were determined to know the moisture and soluble solids (SS) content, pH and total acidity. Briefly, moisture content was analysed by drying in an oven (Red LINE; Binder, Tuttlingen, Germany) at 100 °C for 24 h. SS were analysed using an Anton Paar refractometer (Abbemat 200; Anton Paar, Graz, Germany). Total acidity and pH were analysed with a pH meter (Lab 850; SCHOTT, Germany) after homogenisation of 10 g of tomato peel with 50 ml of distilled water using an Ultra Turrax (DI25 Basic; IKA, Germany). The acidity, expressed as citric acid, was then analysed by potentiometric titration according to the AOAC (1990) method (942.15, ISO 750:1981). The tomato peel sample had a moisture content of about 90%, an average SS content of 0.86°Brix, a pH of 4.34 and a citric acid content of 0.25%.

Experimental Design

A Plackett–Burman experimental design 27−4 with increasing resolution from III to IV via a fold over strategy to 27−3 was used (Table 1) and 16 assays or runs were carried out in a specified trial (randomised order) to identify the most influencing factors affecting the extraction of carotenoids from tomato peels avoiding variations of any external effect (see Table 2 in ‘Results and Discussion’ section).

Seven apparent critical factors (ACFs) were selected based on the experience of our research group and commonly studied factors found in the literature (Periago et al., 2007; Silva et al., 2019; Umair et al., 2021), which were coded Xi, where i = 1–7. Each variable was studied at a low level (−1) and a high level (+1). The following ACFs were selected: SDS volume (SDSv, X1); SDS concentration (SDSC, X2); homogenising intensity (HI, X3); homogenising time (HT, X4); sonication phase (SP, X5); extraction time (ET, X6); ultracentrifugation intensity (UCI, X7). Table 1 shows the ACFs, the assigned codes and their experimental design levels.

After running the first Plackett–Burman experimental design, a response surface methodology according to the Box and Wilson design (Box & Wilson, 1951) was carried out to optimise the selected IFs by selecting different levels of the identified IFs.

Effect of the Apparent Critical Factors on the Carotenoid Extraction

For the extraction of carotenoids and the evaluation of the ACFs, we followed the method described by Fish (2007) with some modifications according to the different levels indicated for the ACFs. For each of the 16 experiments, 1 g of tomato peel by-products was weighed on a precision balance (PA114; Ohaus Pioneer, Pine Brook, USA), and then SDS was added in different volumes (X1, SDSv = 10 or 20 ml) at different concentrations (X2, SDSC = 0.3 or 0.5%). Samples were homogenised using an Ultra-Turrax (DI 25 basic; Staufen, Germany) at different intensities (X3, HI = 8000 or 13,500 rpm) and times (X4; HT = 1 or 2 min) to allow tissue disruption. The pH was adjusted to 7 ± 0.1 using a pH meter (Lab 850; SCHOTT, Germany) to achieve effective solubilisation of chromoplasts in SDS.21 Depending on the experiments, some of the trials were sonicated (X5, Sp = no or yes for 10 min) with the ultrasound (5510; Branson, Danbury, USA) to facilitate the extraction of the chromoplasts. To improve the extraction, the tubes, protected from light with aluminium foil, were placed on an orbital shaker (N12E; OVAN, Barcelona, Spain) for different periods of time (X6, ET = 2 or 12 h) to allow denaturation and solubilisation of cellular components. To remove plant material, the mixture was centrifuged (5804 R; Eppendorf, Germany) at 1562 × g for 15 min. After centrifugation, the supernatant containing carotenoid organelles was kept and the colourless plant tissue at the bottom of the tube was discarded. In this last step, we introduced the main modification to the original procedure described by Fish (2007) because instead of precipitating the chromoplasts with acetonitrile, we proposed to isolate them by ultracentrifugation. Thus, the last ACF was ultracentrifugation at different intensities (X7, UCI = 25,760 or 50,349 × g) for 45 min, using a Beckman centrifuge (J2-21, California, USA). Finally, the pellets were recorded, and the extracted carotenoids were measured by spectrophotometry to determine the yield of each trial.

Optimisation of the Influencing Factors

After identifying the IFs (X1 and X6), a Box–Wilson experimental design (see Table 3 in ‘Results and Discussion’ section) and RSM were applied to optimise the extraction of carotenoids following a microemulsion procedure using SDS. In the ten trials, five different levels were given for each IF, within a range of values previously established. Tomato peel by-products (1 g) were weighed and a 0.3% SDS solution was added in different volumes (X1, SDSv), ranging from 3.8 to 12.2 ml, and the samples were immediately homogenised using an Ultra Turrax (DI 25 basic, Yellow line; Staufen, Germany) at 13,500 rpm for 2 min. The pH was adjusted to neutrality (pHmeter Lab 850; SCHOTT, Germany), and then the samples were sonicated for 10 min (5510; Branson, Danbury, USA). The tubes were then protected from light with aluminium foil and placed on an orbital shaker (N12E; OVAN, Barcelona, Spain) for different times (X6, ET), ranging from 46 min to 9 h and 14 min. To remove plant material, the mixture was centrifuged (5804 R; Eppendorf, Germany) at 1562 × g for 15 min. The supernatant was ultracentrifuged (J2-21; Beckman, California, USA) at 50,349 × g for 45 min. The pellet containing chromoplasts was analysed to obtain different responses: the total carotenoid content by spectrophotometry (R1) and the amounts of the individual carotenoids analysed by HPLC-DAD, β-carotene (R2), Z-isomers of lycopene (R3), all-E-lycopene (R4) and total carotenoids, as the sum of the identified compounds (R5).

Quantification of Total Carotenoids by UV Spectrophotometry

The total carotenoid content was quantified in the pellets isolated in the ACFs study and the optimisation assay of IFs, according to a spectrophotometry method (Dzakovich et al., 2019). Briefly, the pellet containing carotenoids was suspended in 10 ml of hexane/acetone/ethanol (2:1:1; v/v/v) and vortexed (VM-10; WiseMix, Korea), then the samples were sonicated for 2 min and then 2 ml of water was added. The solution was allowed to stand for 5 min to separate into a distinct polar layer and a nonpolar layer (hexane fraction) containing the carotenoids. Carotenoids were measured by reading the absorbance in a spectrophotometer (Evolution 300; Thermo Scientific, England) at λ = 472 nm, the maximum wavelength of absorbance of lycopene. Total carotenoids were expressed as milligrams per 100 g fresh weight (FW) of tomato peel using the molar coefficient of lycopene (E1% 3450).

Quantification of Individual Carotenoids by HPLC-DAD

The HPLC-DAD method was used to determine the individual carotenoids in the IFs optimisation step. The pellets isolated in the ten trials were mixed with 10 ml of hexane/acetone/ethanol solution mentioned above, and 1 ml of the hexane containing carotenoids was evaporated in the speed vacuum concentrator (Concentrator plus; Eppendorf, Germany), then, 250 μl of MeOH/TBME (1:1, v/v) was added, sonicated for a few seconds and injected into the HPLC system (1200; Agilent Technologies, Spain) fitted with a quaternary pump, a degasser, a thermostatic column support, an autosampler and a serial diode detector (DAD). The identification and quantification of carotenoids by chromatographic techniques was carried out according to the method described by González-Barrio et al. (2018). Briefly, chromatographic separation was carried out on a C30 column (250 × 4.6 mm, 5 µm) (Análisis Vinicos S.L., Tomelloso, Spain) at 17 °C, with the mobile phases tert-butyl methyl ether (A) and MeOH (B) and a flow rate of 1 ml/min. The gradient started with 2% of solvent A, reaching 35% of solvent A at 35 min, 60% at 45 min and 60% at 55 min, followed by washing and return to the initial conditions. Carotenoids were identified by their UV spectra and retention times by chromatographic comparison with authentic standards (García-Valverde et al., 2013). β-Carotene (calibration curve 0.16–65 µg/ml; LOQ: 0.08 µg/ml; LOD: 0.014 µg/ml) was quantified at 450 nm, while all-E-lycopene and its Z-isomers were quantified at 472 nm (calibration curve 0.15–60 µg/ml; LOQ: 0.08 µg/ml; LOD: 0.014 µg/ml). The results were expressed as milligrams of carotenoids/100 g FW of tomato peel.

Precipitation of Chromoplasts Containing Carotenoids Using Acetonitrile

Once the protocol for the carotenoids extraction from tomato peels was optimised, we proposed an alternative final step to the method described by Fish (2007) to precipitate chromoplasts containing carotenoids, in which chromoplasts were precipitated using ultracentrifugation instead of the organic solvent acetonitrile (ACN). Thus, we compared both ACN and ultracentrifugation methods. To this end, 11 ml of ACN was added to the supernatant, allowed to stand for 15 min and centrifuged at 1000 × g for 5 min to collect the precipitate rich in carotenoids (Fish, 2007).

Integrity of Chromoplasts by Transmission Electron Microscopy

Transmission electron microscopy (TEM) was carried out to ascertain the integrity of the chromoplasts precipitated by ultracentrifugation in comparison with the original method using ACN (Fish, 2006, 2007). Both samples were covered with solution A (8% formaldehyde, 25 mg calcium chloride and 25% glutaraldehyde and phosphate buffer) and were allowed to fix for 2 h under refrigeration. After three washes with phosphate buffer pH 7.2 for 30 min, post-fixation with 1% osmium tetroxide for 2 h 30 min was performed in the dark and under refrigeration. After washing the sample with phosphate buffer pH 7.2 for 12 h, the samples were covered with uranyl acetate for 2 h under refrigeration. The samples were then dehydrated using ethanol applied at different concentrations. For incorporation into Spurr resin, the above was removed and pure resin was added for 12 h in refrigeration. As a final step before visualization in the JEM-1011 (JEOL) transmission electron microscope with GATAN (ORIUS) digital contrast camera, sections were cut and mounted on grids, then counterstained with uranyl acetate and lead citrate.

Lycopene Purity by Nuclear Magnetic Resonance

Nuclear magnetic resonance (NMR) was performed to determine the lycopene purity of the two carotenoid-rich precipitates isolated by ultracentrifugation or ACN. To do that, 5 mg of the sample was freeze-dried (Lyoquest-80; Telstar, Terrasa, Spain), dissolved in dichloromethane and analysed in a 600-MHz spectrometer (UltraShield; Bruker Advance, Bremen, Germany), adjusting the parameters of the 1H-NMR experiments.

Results and Discussion

Regarding the Plackett–Burman experimental design, Table 2 shows the ACFs total experimental design with two-levels by factor (−1 and +1) and the response values in terms of milligrams of total carotenoids/100 g FW of tomato peel for each one of the 16 experimental conditions tested.

Experiments were carried out on the trial column order to avoid erroneous conclusions due to extraneous sources of variability introduced by the experimenter (Joglekar & May, 1987; Robinson, 2000). To select the significant ACFs, the carotenoid content in the samples were analysed by UV spectrophotometry, as this technique allows easier, faster and cheaper analyses for the initial screening of the total carotenoid content. The results ranged from the lowest value of 0.31 mg carotenoids/100 g in trials 2 and 7 to 1.69 mg carotenoids/100 g in trial 4. The differences in the levels of carotenoids were due to the different conditions used in the assays (trials). The effect of the seven selected ACFs on total carotenoid extraction and the statistical significance are shown in Table 3. The results obtained in the screening phase can be discussed on the basis of three empirical statistical principles, i.e. the sparsity principle (only a small number of the candidate factors are critical), the hierarchy principle (primary effects are more likely to be critical than secondary effects from two-factor interactions, which in turn are more likely to be critical than three-factor interactions, and so forth) and the heredity principle (it is unusual for an interaction to be critical unless at least one of the factors involved has an active primary critical effect). A strong effect was considered when p ≤ 0.25, and then the ACFs with this significance were identified as the IFs.

Of the seven ACFs, only three were recognised as IFs, the SDS volume (SDSv) (X1), the sonication phase (SP) (X5) and the extraction time (ET) (X6). In the case of factor X1 (SDSv), a significant (p ≤ 0.244) but negative effect (− 0.224) was obtained, which explains that a better extractability of carotenoids was achieved when the low level of this factor (level −1) was used, 10 ml of SDS instead of 20 ml. The volume of SDS added to the sample determined the solid–liquid ratio and was considered the most significant variable for the extraction of carotenoids with SDS in brown algae (Vieira et al., 2018), since when the solid–liquid ratio decreased, the yield of extraction of carotenoids increased. Therefore, our results agree with those findings, since the volume of 10 ml of SDS (solid/liquid ratio 1:10) was preferable compared to the 20 ml (solid/liquid ratio 1:20).

Previous works pointed out the importance of the selection of the SDS concentration (SDSC) (X2) to promote cell disruption and assist the solubilisation of hydrophobic carotenoids from different food matrices (Fish, 2006; Vieira et al., 2018). This factor had a negative effect in our experiment, where 0.3% SDS (level −1) was preferred to 0.5%. Although this variable was not significant in the experimental design, the effect of the SDSC to obtain a better yield of extraction of carotenoids may depend on the critical micellar concentration (CMC), which ensures an appropriate formation of detergent micelles. Our results agree with those reported by Fish (2006, 2007) in different plant systems, who described that 0.3% SDS was enough to achieve the extraction of carotenoids. The increase of the concentration of SDS from a 1.3 × CMC (0.3% SDS) to a 2.2 × CMC (0.5% SDS) did not have a significant effect on improving the carotenoid extraction from tomato peels, so it is reasonable to use the lowest concentration of this anionic surfactant. However, our findings are not in agreement with those reported by Vieira et al. (2018), who described that the capacity of SDS to extract carotenoids from the brown algae seemed to depend on the CMC until reaching 20 × CMC. Factors X3 (homogenisation intensity, HI) and X4 (homogenisation time, HT) had an effect with a positive sign but without statistical significance; therefore, we chose level +1 (13,500 rpm and 2 min) for the following experiments, considering that better homogenisation of the tomato peels would be preferable to facilitate the extraction of intact chromoplasts.

Factor X5 (sonication phase, SP) was selected and studied as a qualitative factor (yes/no as level +1/level −1, respectively) and had a significant effect (p ≤ 0.197) with a positive effect (0.251). The positive level (level +1), which introduced a sonication phase of 10 min, should be considered as an IF to improve the extraction of carotenoids from tomato peels, being a constant in the next optimisation phase. In this regard, ultrasound pre-treatment for lycopene extraction has been recognised as an efficient method to improve the yield and purity of the extracts while consuming less time and solvents (Amiri-Rigi et al., 2016). Other authors described that the use of ultrasounds during the extraction process could be the cause of the formation of lycopene isomers in the samples (Xu & Pan, 2013), which in our work accounted for 5–10% of the total lycopene obtained.

Factor X6 (ET), when stirred for 2 h (level −1) or 12 h (level +1) protected from light, showed a negative significant effect (−0.539, p ≤ 0.016) (Table 3). Although a longer period of homogenisation might be expected to improve the solubilisation of chromoplasts in the SDS, the sensitivity of carotenoids to external factors (such as temperature or oxygen) might have determined that homogenisation for 12 h resulted in a lower extraction yield of carotenoids than for 2 h. Fish (2006) found no significant differences in the amount of lycopene extracted from watermelon flesh for additional treatment times from 1 h up to 24 h, showing that there were no losses of lycopene during the extraction and solubilisation. Since tomato products require a longer contact time with SDS for carotenoids extraction (Fish, 2007), we tested in this study 2 and 12 h of maceration and shaking in 0.3% SDS, showing that 12 h had a significant negative effect. For this reason, 2 h was enough time to facilitate the solubilisation of the chromoplasts in the extractant solution, considering this step as IF for the low level (level −1). The last ACF X7 was the UCI, ranging from 25,760 × g (level −1) to 50,349 × g (level +1). Despite the very low value of the positive effect of this factor (0.065), without a significance, we considered the level +1 (50,349 × g) to be preferable for the second phase of the study. Therefore, out of the three significant IFs obtained in the first phase on the Plackett–Burman experimental design, only two of them (SDSV and ET) were considered for the optimisation phase, whereas, as mentioned above, the sonication phase was introduced as a step in the procedure.

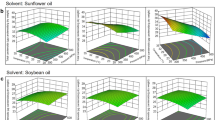

Once the two strongest IFs (SDSV and ET) were identified, RSM was used based on the results obtained for the Box–Wilson experimental design (Table 4) to find out the best analytical conditions for five responses of the extracted carotenoids analysed (R1 − R5). This optimisation experiment suggested the evaluation of five different levels for each of the selected IFs in order to ascertain a potential linear or quadratic response model in the extraction of total carotenoids. Ten different trials were carried out and the responses were: total carotenoids by spectrophotometry (R1), β-carotene (R2), Z-isomers of lycopene (R3), all-E-lycopene (R4) and total carotenoids by HPLC-DAD (R5), expressed as milligrams per 100 g FW tomato peel (Table 4).

As expected, the major carotenoid found in the tomato peel was all-E-lycopene followed by β-carotene (García-Valverde et al., 2013; Periago et al., 2002) (Table 4 and Fig. 1). The yields of carotenoid extraction in the different experiments varied according to the trial (analytical procedure) and the individual compounds analysed. Total carotenoids by spectrophotometry (R1) ranged from 0.69 to 3.62 mg/100 g FW, β-carotene (R2) ranged from 0.07 to 0.60 mg/100 g FW, Z-isomers of lycopene (R3) varied from 0.06 to 0.20 mg/100 g FW, while all-E-lycopene (R4) showed the highest amounts from 1.07 to 3.09 mg/100 g FW. Total carotenoids (R5), determined as the sum of the individual compounds, ranged from 0.53 to 3.88 mg/100 g FW. Trial 1 (11 ml SDS and 8 h of shaking) gave the highest concentration of carotenoids for all responses, with values of 0.59, 0.19, 3.08 and 3.88 mg/100 g FW for R2, R3, R4 and R5, respectively, except for R1, which was higher in trial 6 than in trial 1. In contrast, assay 2 (3.8 ml SDS and 5 h shaking) had the lowest carotenoid concentration for all responses.

The highest value obtained for carotenoid extraction from tomato peels (3.88 mg/100 g FW corresponding to 40 mg/100 g DW) was higher than previous results from our research group using organic solvents combined with ultrasound, maceration or enzymatic assisted extraction (3–4 mg lycopene/100 g DW) (Navarro-González et al., 2011). In addition, our values were also within the wide range described in the scientific literature for lycopene extraction from tomato peels using organic solvents (30–80 mg/100 g tomato peels DW) (Ho et al., 2015; Szabo et al., 2021). In comparison with other eco-friendly methods, supercritical CO2 showed about 4 mg lycopene/100 g peel tomato DW (Kehili et al., 2017) and the use of microemulsion systems using the surfactant saponin reported values about 30 mg/100 g DW (Amiri-Rigi & Abbasi, 2017). Thus, the present extraction method using SDS allows a higher extraction yield of carotenoids compared to other green methods, avoiding the use of organic co-solvents, high investment in technology used at pilot or industrial scale, and high energy costs. In addition, the content of carotenoids extracted can vary depending on the ripening stage of the tomatoes and several factors including plant nutrition, environment and genotype. These factors significantly impact carotenoid biosynthesis, affecting the carotenoid yields when compared to results from other authors (García-Valverde et al., 2013; Periago et al., 2009).

As a result of this second stage of optimisation, SDSV (X1) had a positive and significant effect (p ≤ 0.05) for all the responses analysed (Table 5), whereas for ET (X6), although a positive effect was also observed, it was not significant for any of the responses. However, the interaction between X1 and X6 was significant for all responses, suggesting that higher values of both variables resulted in higher carotenoid extraction yields.

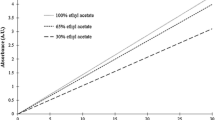

The Box–Wilson optimisation experimental design confirmed that increasing the volume of SDS between 3.8 and 12.2 ml had a positive effect on the solubilisation and extraction of carotenoids from tomato peels (p = 0.012 for R1; 0.008 for R2; 0.007 for R3; 0.008 for R4; 0.007 for R5, respectively). The two-dimensional plot of the two-way interaction between factors X1 (SDSV) and X6 (ET) is shown in Fig. 2. In general, the extraction yield of carotenoids (for the five responses analysed) can be similarly achieved at both a high volume of 0.3% SDS and a long extraction time. The stationary point of the system was found at a volume of 11.9 ml of SDS and an extraction time of 8.2 h (Fig. 2) since the yield of carotenoid extraction did not increase when the highest volume of SDS was used. This behaviour indicated that the yield of carotenoid extraction increased up to the saturation point.

On the other hand, R2 and R4 responses, corresponding to β-carotene and all-E-lycopene, respectively, were highly correlated with R5 (total carotenoids by HPLC), with correlation coefficient values of 0.955 and 0.996, meaning that the effects of X1 and X2 were very similar in the extraction of both compounds. In addition, the correlation between total carotenoids analysed spectrophotometrically by UV–VIS and HPLC-DAD was lower (r = 0.86), which could be explained because the colorimetric method overestimates the content of total carotenoids in comparison with the chromatography analysis that quantified individual compounds (Islam & Schweigert, 2015).

The final optimised protocol, according to the stationary point conditions, is shown in Fig. 3, and the steps were as follows: 1 g of tomato peels was mixed with 11.9 ml of 0.3% SDS, immediately homogenised (2 min, 13,500 rpm) and the pH was adjusted to ~ 7. The samples were then placed in an ultrasonic bath and sonicated for 10 min, after which the samples were covered with aluminium foil and shaken for 8.2 h at room temperature to facilitate the solubilization of the chromoplasts in the SDS solvent. Then, the vegetal material was removed by centrifugation at 1562 × g for 15 min. Finally, the supernatant containing the chromoplasts was subjected to ultracentrifugation (UC) (50,349 × g, 45 min), and the precipitate was recovered as the carotenoid-rich fraction. As mentioned above, the final step of UC was selected and tested as a novel step for disrupting the microemulsion and extracting chromoplast-containing carotenoids, instead of using acetonitrile (ACN) and avoiding the use of this organic solvent described by Fish (2007) for chromoplast precipitation. Thus, the optimised method was applied to the extraction of carotenoids from tomato peels, comparing the effect of the final step UC versus ACN on the yield of total carotenoids analysed by HPLC-DAD.

In our optimised protocol, the UC method led to a higher carotenoid extraction than ACN since the amounts of total carotenoids were 3.88 and 2.05 mg/100 g FW after UC and ACN addition, respectively.

Moreover, we used the TEM and NMR analyses to compare these two precipitation methods. TEM analysis was carried out to evaluate the presence of the intact chromoplasts after the precipitation with UC and ACN (Fig. 4).

In the case of the ACN-precipitated sample (image A), no concise cellular structures were observed, whereas in the UC-precipitated sample (image B), spherical microbodies could be seen, likely corresponding to intact chromoplasts with some amorphous materials representing residual cell debris. Fish (2006) also found spherical microbodies with a similar structure and size, which were identified as lycopene-containing chromoplasts in an SDS extract of watermelon. In addition, Schweiggert et al. (2011) also observed a similar organelle structure in tomato samples when investigating the effect of chromoplast morphology on carotenoid bioavailability. These images confirmed that the extraction of carotenoids from tomato peels followed by UC allowed the isolation of the carotenoid-containing chromoplasts, firstly due to the solubilisation of the chromoplasts in SDS and secondly after the precipitation of these organelles during UC. On the contrary, in the pellet isolated with ACN we could not find any chromoplast structure, only some amorphous materials after the TEM observation.

In order to confirm the presence of the major carotenoid lycopene in the extract obtained from tomato peels, we used NMR to tentatively identify the molecule by chemical shifts of the proton and carbon signals. This technique provides specific structural information about the molecules in a sample. Chemical shifts in the NMR spectrum can be used to distinguish between different chemical structures and is preferred for assessing the purity of compounds compared to UV spectroscopy or mass spectroscopy, as the former cannot distinguish between structurally similar compounds, and the second cannot give specific details about the purity and structure of compounds (Liu et al., 2019; Pauli et al., 2014). Figure 5 shows the 1H-NMR spectrum of both extracts, showing clear differences between the two samples.

The sample precipitated with ACN (blue line) showed a much lower intensity than the one precipitated with UC (red line). The signal of the proton and carbon chemical shifts are in agreement with the all-E-lycopene spectrum reported in the scientific literature (Luxsuwong et al., 2014; Takehara et al., 2013; Tiziani et al., 2006). These results suggest that UC allowed the isolation of intact chromoplasts after the solubilization in SDS, protecting the carotenoids from exposure to external agents and, consequently, avoiding their degradation. On the other hand, a higher degradation of lycopene was observed in the sample precipitated with ACN since, as mentioned above, after the addition of ACN the chromoplast structure could be affected and, therefore, the carotenoids could be more exposed to the different factors affecting their degradation. Thus, based on the TEM and NMR results, it seems that UC, as the last step of the present method, protected the whole chromoplast structure and prevented the degradation of carotenoids. The microemulsion yields a highly concentrated residue abundant in lycopene after the elimination of aqueous supernatant containing SDS. From a toxicological point of view, the concentration of SDS used in this procedure is within the oral dosage forms in pharmacological industry (0.2–1.5%) (EMA, 2015) and the expected residues of SDS should be low. In a subsequent phase of upscaling this method, the process needs the development a procedure to solubilise the lycopene-rich extract and to prepare a new ingredient that might be used in the food industry and classified as ‘novel food’, assuring the safety to human consumption.

Conclusions

The use of the biodegradable surfactant SDS for the extraction of carotenoids, mainly lycopene, from tomato peels has been optimised, providing the agri-food companies with a sustainable technological solution for the valorisation of by-products for the extraction of a lycopene-rich extract. The use of ultracentrifugation as a final step in this carotenoid extraction method for the precipitation of solubilised carotenoid-containing chromoplasts may have greater advantages than the use of acetonitrile since it involves a green method eliminating the contamination provided by the organic solvent, and obtaining an extract richer in lycopene with intact chromoplasts that could prevent their oxidation. This optimised protocol demonstrates the effectiveness of the biodegradable solvent SDS for extraction of liposoluble compounds, such as lycopene. Thus, this method allows us to respond to the great demand from the food industry to produce innovative added-value ingredients from by-products using a sustainable extraction method. The extracted carotenoids could be used for the technological and nutritional enrichment of novel foods and/or the design of nutraceuticals or cosmetics.

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Amiri-Rigi, A., & Abbasi, S. (2017). Stability assessment of lycopene microemulsion prepared using tomato industrial waste against various processing conditions. Journal of the Science of Food and Agriculture, 97(14), 4922–4928. https://doi.org/10.1002/JSFA.8368

Amiri-Rigi, A., Abbasi, S., & Scanlon, M. G. (2016). Enhanced lycopene extraction from tomato industrial waste using microemulsion technique: Optimization of enzymatic and ultrasound pre-treatments. Innovative Food Science and Emerging Technologies, 35, 160–167. https://doi.org/10.1016/j.ifset.2016.05.004

AOAC. (1990). Official methods of analysis. (Kenneth Helrich, Ed.) (Vol. 15). Arlington, Virginia, USA.

Araujo, P. W., & Brereton, R. G. (1996). Experimental design II. Optimization. TrAC - Trends in Analytical Chemistry, 15(2), 63–70. https://doi.org/10.1016/0165-9936(96)80762-X

Box, G. E. P., & Hunter, J. S. (1961). The 2κ-p fractional factorial designs - Part I. Techometrics, 3, 311–351.

Box, G. E. P., & Wilson, K. B. (1951). On the experimental attainment of optimum conditions. Journal of the Royal Statistical Society: Series B (methodological), 13(1), 1–38. https://doi.org/10.1111/J.2517-6161.1951.TB00067.X

Cornell, J. A. (1990). How to apply response surface methodology. Journal of Quality Technology, 4, 82. https://doi.org/10.1080/00224065.1991.11979357

Ctaex. (2022). Production - Industrial Tomato Observatory. https://observatoriotomate.com/. Accessed 3 Mar 2023

Di Mascio, P., Devasagayam, T. P. A., Kaiser, S., & Sies, H. (1990). Carotenoids, tocopherols and thiols as biological singlet molecular oxygen quenchers. Biochemical Society Transactions, 18(6), 1054–1056. https://doi.org/10.1042/BST0181054

Dzakovich, M. P., Gas-Pascual, E., Orchard, C. J., Sari, E. N., Riedl, K. M., Schwartz, S. J., et al. (2019). Analysis of tomato carotenoids: Comparing extraction and chromatographic methods. Journal of AOAC International, 102(4), 1069–1079. https://doi.org/10.5740/JAOACINT.19-0017

EMA. (2015). Background review for sodium laurilsulfate used as an excipient. European Medicine Agency, Committee for Human Medicinal Products. EMA/CHMP/351898/2014.

FDA. (2023). Food additives permitted for direct addition to food for human consumption. Food and Drug Administration, 21, CFR172.822.

Fish, W. W. (2006). Interaction of Sodium Dodecyl Sulfate with Watermelon Chromoplasts and Examination of the Organization of Lycopene within the Chromoplasts. https://doi.org/10.1021/JF061468+

Fish, W. W. (2007). Novel procedure for the extraction and concentration of carotenoid-containing chromoplasts from selected plant systems. Journal of Agricultural and Food Chemistry, 55(4), 1486–1490. https://doi.org/10.1021/jf0626213

García-Valverde, V., Navarro-González, I., García-Alonso, J., & Periago, M. J. (2013). Antioxidant bioactive compounds in selected industrial processing and fresh consumption tomato cultivars. Food and Bioprocess Technology, 6(2), 391–402. https://doi.org/10.1007/S11947-011-0687-3

González-Barrio, R., Periago, M. J., Luna-Recio, C., Garcia-Alonso, F. J., & Navarro-González, I. (2018). Chemical composition of the edible flowers, pansy (Viola wittrockiana) and snapdragon (Antirrhinum majus) as new sources of bioactive compounds. Food Chemistry, 252, 373–380. https://doi.org/10.1016/j.foodchem.2018.01.102

Gouda, M., El-Din Bekhit, A., Tang, Y., Huang, Y., Huang, L., He, Y., & Li, X. (2021). Recent innovations of ultrasound green technology in herbal phytochemistry: a review. Ultrasonics Sonochemistry. Elsevier B.V. https://doi.org/10.1016/j.ultsonch.2021.105538

Ho, K. K. H. Y., Ferruzzi, M. G., Liceaga, A. M., & San Martín-Gonz Alez, M. F. (2015). Microwave-assisted extraction of lycopene in tomato peels: effect of extraction conditions on all-trans and cis-isomer yields. https://doi.org/10.1016/j.lwt.2014.12.061

Islam, K. M. S., & Schweigert, F. J. (2015). Comparison of three spectrophotometric methods for analysis of egg yolk carotenoids. Food Chemistry, 172, 233–237. https://doi.org/10.1016/J.FOODCHEM.2014.09.045

Joglekar, A., & May, A. T. (1987). Product excellence through design of experiments. Cereal Foods World, 32, 857–868.

Kehili, M., Kammlott, M., Choura, S., Zammel, A., Zetzl, C., Smirnova, I., et al. (2017). Supercritical CO2 extraction and antioxidant activity of lycopene and β-carotene-enriched oleoresin from tomato (Lycopersicum esculentum L.) peels by-product of a Tunisian industry. Food and Bioproducts Processing, 102, 340–349. https://doi.org/10.1016/J.FBP.2017.02.002

Kruk, J., & Szymańska, R. (2021). Singlet oxygen oxidation products of carotenoids, fatty acids and phenolic prenyllipids. Journal of Photochemistry and Photobiology B: Biology, 216, 112148. https://doi.org/10.1016/J.JPHOTOBIOL.2021.112148

Liu, Y., Romijn, E. P., Verniest, G., Laukens, K., & De Vijlder, T. (2019). Mass spectrometry-based structure elucidation of small molecule impurities and degradation products in pharmaceutical development. TrAC - Trends in Analytical Chemistry. Elsevier B.V. https://doi.org/10.1016/j.trac.2019.115686

López-Cruz, R., Sandoval-Contreras, T., & Iñiguez-Moreno, M. (2023). Plant pigments: Classification, extraction, and challenge of their application in the food industry. Food and Bioprocess Technology, 2023(1), 1–17. https://doi.org/10.1007/S11947-023-03075-4

Luxsuwong, D., Indranupakorn, R., & Wongtrakul, P. (2014). Preparation of vesicles entrapped lycopene extract. Journal of Oleo Science, 63(6), 645–652. https://doi.org/10.5650/JOS.ESS13216

Madia, V. N., De Vita, D., Ialongo, D., Tudino, V., De Leo, A., Scipione, L., et al. (2021). Recent advances in recovery of lycopene from tomato waste: a potent antioxidant with endless benefits. Molecules (Basel, Switzerland), 26(15). https://doi.org/10.3390/MOLECULES26154495

Meléndez-Martínez, A. J., Vicario, I. M., & Heredia, F. J. (2004). Estabilidad de los pigmentos carotenoides en los alimentos. Archivos Latinoamericanos de Nutrición, 54.

Meléndez‐Martínez, A. J. (2019). An overview of carotenoids, apocarotenoids and vitamin A in agro‐food, nutrition, health and disease. Molecular Nutrition & Food Research, 1801045. https://doi.org/10.1002/mnfr.201801045

Méndez-Carmona, J. Y., Ascacio-Valdes, J. A., Alvarez-Perez, O. B., Hernández-Almanza, A. Y., Ramírez-Guzman, N., Sepúlveda, L., et al. (2022). Tomato waste as a bioresource for lycopene extraction using emerging technologies. Food Bioscience, 49. https://doi.org/10.1016/J.FBIO.2022.101966

Messinese, E., Pitirollo, O., Grimaldi, M., Milanese, D., Sciancalepore, C., & Cavazza, A. (2023). By-products as sustainable source of bioactive compounds for potential application in the field of food and new materials for packaging development. Food and Bioprocess Technology, 2023(1), 1–22. https://doi.org/10.1007/S11947-023-03158-2

Navarro-González, I., García-Valverde, V., García-Alonso, J., & Periago, M. J. (2011). Chemical profile, functional and antioxidant properties of tomato peel fiber. Food Research International, 44(5), 1528–1535. https://doi.org/10.1016/j.foodres.2011.04.005

Navarro-González, I., Pérez-Sánchez, H., Martín-Pozuelo, G., García-Alonso, J., & Periago, M. J. (2014). The inhibitory effects of bioactive compounds of tomato juice binding to hepatic HMGCR: in vivo study and molecular modelling. PLoS ONE, 9(1). https://doi.org/10.1371/journal.pone.0083968

Nonglait, D. L., & Gokhale, J. S. (2023). Review insights on the demand for natural pigments and their recovery by emerging microwave-assisted extraction (MAE). Food and Bioprocess Technology, 2023(1), 1–25. https://doi.org/10.1007/S11947-023-03192-0

Pauli, G. F., Chen, S. N., Simmler, C., Lankin, D. C., Gödecke, T., Jaki, B. U., et al. (2014). Importance of purity evaluation and the potential of quantitative 1H NMR as a purity assay. Journal of Medicinal Chemistry, 57(22), 9220–9231. https://doi.org/10.1021/jm500734a

Pereira, C. G., & Meireles, M. A. A. (2010). Supercritical fluid extraction of bioactive compounds: fundamentals, applications and economic perspectives. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-009-0263-2

Periago, M. J., García-Alonso, J., Jacob, K., Olivares, A. B., Bernal, M. J., Iniesta, M. D., et al. (2009). Bioactive compounds, folates and antioxidant properties of tomatoes (Lycopersicum esculentum) during vine ripening. International Journal of Food Sciences and Nutrition, 60(8), 694–708. https://doi.org/10.3109/09637480701833457

Periago, M. J., Martínez-Valverde, I., Chesson, A., & Provan, G. (2002). Phenolic compounds, lycopene and antioxidant activity in commercial varieties of tomato (Lycopersicum esculentum). Journal of the Science of Food and Agriculture, 82(3), 323–330. https://doi.org/10.1002/JSFA.1035

Periago, M. J., Rincón, F., Jacob, K., García-Alonso, J., & Ros, G. (2007). Detection of key factors in the extraction and quantification of lycopene from tomato and tomato products. Journal of Agricultural and Food Chemistry, 55(22), 8825–8829. https://doi.org/10.1021/JF0705623

Robinson, G. K. (2000). Practical strategies for experimenting. Wiley, 1st edition (January 15, 2000).

Saini, R., Rengasamy, K., Mahomoodally, F., & Keum, Y. (2020). Protective effects of lycopene in cancer, cardiovascular, and neurodegenerative diseases: an update on epidemiological and mechanistic perspectives. Pharmacological research, 155. https://doi.org/10.1016/J.PHRS.2020.104730

Schieber, A., & Carle, R. (2005). Occurrence of carotenoid cis-isomers in food: Technological, analytical, and nutritional implications. Trends in Food Science & Technology, 16(9), 416–422. https://doi.org/10.1016/J.TIFS.2005.03.018

Schweiggert, R. M., Steingass, C. B., Heller, A., Esquivel, P., & Carle, R. (2011). Characterization of chromoplasts and carotenoids of red- and yellow-fleshed papaya (Carica papaya L.). Planta, 234(5), 1031–1044. https://doi.org/10.1007/S00425-011-1457-1

Silva, Y. P. A., Ferreira, T. A. P. C., Celli, G. B., & Brooks, M. S. (2019). Optimization of lycopene extraction from tomato processing waste using an eco-friendly ethyl lactate–ethyl acetate solvent: A green valorization approach. Waste and Biomass Valorization, 10(10), 2851–2861. https://doi.org/10.1007/s12649-018-0317-7

Szabo, K., Dulf, F. V., Teleky, B. E., Eleni, P., Boukouvalas, C., Krokida, M., et al. (2021). Evaluation of the bioactive compounds found in tomato seed oil and tomato peels influenced by industrial heat treatments. Foods, 10(1). https://doi.org/10.3390/FOODS10010110

Takehara, M., Nishimura, M., Kuwa, T., Inoue, Y., Kitamura, C., Kumagai, T., & Honda, M. (2013). Characterization and thermal isomerization of (all-E)-lycopene. https://doi.org/10.1021/jf404497k

Tiziani, S., Schwartz, S. J., & Vodovotz, Y. (2006). Profiling of carotenoids in tomato juice by one- and two-dimensional NMR. Journal of Agricultural and Food Chemistry, 54(16), 6094–6100. https://doi.org/10.1021/JF061154M

Umair, M., Jabbar, S., Nasiru, M. M., Lu, Z., Zhang, J., Abid, M., et al. (2021). Ultrasound-assisted extraction of carotenoids from carrot pomace and their optimization through response surface methodology. Molecules. https://doi.org/10.3390/molecules26226763

Vieira, F. A., Guilherme, R. J. R., Neves, M. C., Rego, A., Abreu, M. H., Coutinho, J. A. P., & Ventura, S. P. M. (2018). Recovery of carotenoids from brown seaweeds using aqueous solutions of surface-active ionic liquids and anionic surfactants. Separation and Purification Technology, 196, 300–308. https://doi.org/10.1016/j.seppur.2017.05.006

Xu, Y., & Pan, S. (2013). Effects of various factors of ultrasonic treatment on the extraction yield of all-trans-lycopene from red grapefruit (Citrus paradise Macf.). Ultrasonics Sonochemistry, 20(4), 1026–1032. https://doi.org/10.1016/J.ULTSONCH.2013.01.006

Yolmeh, M., & Jafari, S. M. (2017). Applications of response surface methodology in the food industry processes. Food and Bioprocess Technology, 10(3), 413–433. https://doi.org/10.1007/S11947-016-1855-2

Zuorro, A., Lavecchia, R., Medici, F., & Piga, L. (2013). Enzyme-assisted production of tomato seed oil enriched with lycopene from tomato pomace. Food and Bioprocess Technology, 6(12), 3499–3509. https://doi.org/10.1007/s11947-012-1003-6

Acknowledgements

The authors thank Dr. R. Gonzalez-Barrio for her help with carotenoid identification by HPLC-DAD, Dr. F.J. García-Alonso for his help with carotenoid extraction methods, and the ACTI scientific services (University of Murcia) for their support with NMR and TEM techniques.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. NB was granted by a ‘Juan de la Cierva Incorporación’ (IJC-2020-044496-I) post-doctoral contract funded by MCIN/AEI/MCIN/AEI/10.13039/501100011033 and European Union NextGenerationEU/PRTR.

Author information

Authors and Affiliations

Contributions

BOF: investigation, formal analysis, data curation, visualization, writing—original draft. NB: conceptualisation, validation, writing—review and editing. FR: methodology, writing—review and editing. MJP: conceptualisation, resources, writing—review and editing, supervision, funding acquisition. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ferrando, B.O., Baenas, N., Rincón, F. et al. Green Extraction of Carotenoids from Tomato By-products Using Sodium Dodecyl Sulphate. Food Bioprocess Technol 17, 3017–3030 (2024). https://doi.org/10.1007/s11947-023-03292-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03292-x