Abstract

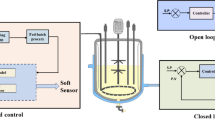

Sclerotium rolfsii ATCC 15205 was cultivated in continuous culture (48 l reactor volume) for scleroglucan production. The maximum volumetric productivity (Q P max) amounted to 7.2 g/ld and was more than twice as high as in comparable batchwise cultivations. In addition, the relation between (a) volumetric productivity (Q P [g/ld]) and product yield (Y Glucan/Glucose [1]), (b) volumetric productivity and product quality (M W [g/mol]), and (c) product quality and impeller tip speed (Nd [m/s]) was studied in continuous culture. It was found, that an increase in volumetric productivity led to a decline in product yield and product quality. Furthermore, an impeller tip speed of >0.7 m/s decreased the attainable product quality considerably. Based on these results, the impact of the operational setpoint of the process in terms of oxygen supply and reactor scale on the economics of scleroglucan production was discussed. In contrast to batchwise cultivation, scleroglucan production in continuous culture proved to be not feasible under non-aseptic conditions.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 4 February 1999

Rights and permissions

About this article

Cite this article

Schilling, B. Sclerotium rolfsii ATCC 15205 in continuous culture: Economical aspects of scleroglucan production. Bioprocess Engineering 22, 57–61 (2000). https://doi.org/10.1007/PL00009102

Issue Date:

DOI: https://doi.org/10.1007/PL00009102