Abstract

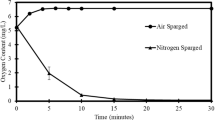

Data from full scale marked ball tests are used to demonstrate the effects of abrasion, corrosion, and impact on overall wear rate. The predominate wear mechanism need be identified before the optimum alloy can be chosen for the grinding media. Use of high chromium grinding media often results in increased mill efficiency due to shape retention. Thus, a benefit from energy savings can result as well as a reduction in wear rate. Converting from steel to cast high chromium grinding media requires close association and cooperation between producer and consumer in order to properly conduct these studies.

Similar content being viewed by others

References

Diesburg, D.E., and Borik, F., 1974 “Optimizing Abrasion Resistance and Toughness in Steels and Irons for the Mining Industry,” Materials for the Mining Industry, Climax Molybdenum Co., pp. 15–42.

Fairhurt, W., and Rohrig, K., 1974 “Abrasion Resistant High-Chromium White Cast Irons,” Foundry Trade Journal, May 30, pp 685–698.

Metals Handbook, 9th ed., Vol. 1, American Society for Metals, Metals Park, OH, pp. 75–96, 448–465, 823–836.

Physics and Chemistry Handbook, 1972, 53rd ed., Chemical Rubber Co., Cleveland, OH, p. F18.

Author information

Authors and Affiliations

Additional information

SME preprint 89–171, SME Annual Meeting, Las Vegas, NV, February, 1989. M&MP paper 89–633. Discussion of this paper must be submitted, in duplicate, prior to Jan. 31, 1990.

Rights and permissions

About this article

Cite this article

Sailors, R.H. Cast high chromium media in wet grinding. Mining, Metallurgy & Exploration 6, 172–178 (1989). https://doi.org/10.1007/BF03403459

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03403459