Abstract

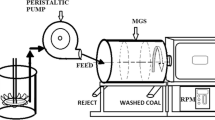

One of the main objectives of this study was to evaluate a fine-coal cleaning circuit using an enhanced gravity separator specifically for a high sulfur coal application. The evaluation not only included testing of individual unit operations used for fine-coal classification, cleaning and dewatering, but also included testing of the complete circuit simultaneously. At a scale of nearly 2 t/h, two alternative circuits were evaluated to clean a minus 0.6-mm coal stream utilizing a 150-mm-diameter classifying cyclone, a linear screen having a projected surface area of 0.5 m2, an enhanced gravity separator having a bowl diameter of 250 mm and a screen-bowl centrifuge having a bowl diameter of 500 mm. The cleaning and dewatering components of both circuits were the same; however, one circuit used a classifying cyclone whereas the other used a linear screen as the classification device. An industrial size coal spiral was used to clean the 2- x 0.6-mm coal size fraction for each circuit to estimate the performance of a complete fine-coal circuit cleaning a minus 2-mm particle size coal stream. The “linear screen + tenhanced gravity separator + screen-bowl circuit” provided superior sulfur and ash-cleaning performance to the alternative circuit that used a classifying cyclone in place of the linear screen. Based on these test data, it was estimated that the use of the recommended circuit to treat 50 t/h of minus 2-mm size coal having feed ash and sulfur contents of 33.9% and 3.28%, respectively, may produce nearly 28.3 t/h of clean coal with product ash and sulfur contents of 9.15% and 1.61%, respectively.

Similar content being viewed by others

References

Fiscor, S., and Lyles, J., 2004, “Prep plant population reflects industry,” Key Stone Coal Industry Manual, 2004, pp. 232–238.

Honaker, R.Q., Paul, B.C., Wang, D., and Ho, K., 1995, “Enhanced gravity separation: an alternative to flotation,” High Efficiency Coal Preparation: An International Symposium, S.K. Kawatra, ed., Society for Mining, Metallurgy and Exploration, Inc., Littleton, Colorado, 1995, pp: 69–78.

Kroeger, E.B., and Mohanty, M.K., 2004, “On-Site Demonstration of the Pansep Screen,” Final Technical Report: Illinois Department of Commerce and Economic Opportunity/Illinois Clean Coal Institute, ICCI Project Number: 03-1/8.1 B-2), Carterville, Illinois, September.

Luttrell, G.H., Honaker, R.Q., and Philips, D., 1995, “"Enhanced gravity separators: New alternatives for fine coal cleaning,” In Proceedings, 12th International Coal Preparation Conference, Lexington, Kentucky, pp. 282–292.

McAlister, S., 1998, “Development of the Enhanced gravity separators,” Preprint 98-172, presented at the SME Annual Meeting, March 9–11, Orlando, Florida, Society of Mining, Metallurgy and Exploration, Inc., Littleton, Colorado.

Mohanty, M.K., and Honaker R.Q., 1999, “Evaluation of the Altair centrifugal jig for fine coal separation,” Coal Preparation, Vol. 20, pp. 85–106.

Mohanty, M.K., Wang, Z., Gupta, V., Launius, D., Biswal, S.K., Kroeger, E.B., and Hirschi, J., 2005, “ln-plant testing of the Pansep screen,” Coal Preparation, Volume 25, No.1, pp. 15–30.

Olson, T.J., and Aplan, F.F., 1984, “The floatability of locked particles in coal flotation systems,” in Proceedings of the 2nd International Congress on Applied Mineralogy in the Minerals Industry, Los Angeles, California, pp. 367–393.

Olson, T.J., and Aplan, F.F., 1987, “The effect of frothing and collecting agents on the flotation of coal, pyrite and locked particles in a coal flotation system,” in Proceedings of Processing and Utilization of High Sulfur Coals II, pp. 71–82.

Riley, D.M., Firth, D.M., and Lockhart, N.C., 1995, “Enhanced gravity separation,” High Efficiency Coal Preparation: An International Symposium, S.K. Kawatra, ed., Society for Mining, Metallurgy, and Exploration, Inc., Littleton, Colorado, pp. 79–88.

Venkatraman, P., Luttrell, G.H., Yoon, R.-H, Knoll, F.S., Kow, W.S., and Mankosa, M.J., 1995, “Fine coal cleaning using multi-gravity separator,” High Efficiency Coal Preparation: An International Symposium, S.K. Kawatra, ed., Society for Mining, Metallurgy, and Exploration, Inc., Littleton, Colorado, pp. 109–117.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mohanty, M.K., Samal, A.R. & Palit, A. Evaluation of an enhanced gravity-based fine-coal circuit for high-sulfur coal. Mining, Metallurgy & Exploration 25, 13–18 (2008). https://doi.org/10.1007/BF03403380

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03403380