Abstract

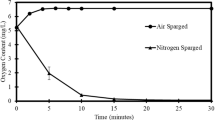

Cathodic protection using impressed current was employed to reduce mill wall wear during ball milling. Wear rates were determined from weight-loss measurements made on four 1-in.-diam mild steel coupons that were installed flush with the interior surface of the mill wall. Grinding tests were conducted on quartz, pyrite and quartz-pyrite mixtures at pH levels of 4.6, 7.1 and 9.2. Cathodic protection was shown to reduce mill wear by 30% to 60%.

An examination of the coupon surfaces using scanning electron microscopy showed that cathodic protection greatly reduced pitting corrosion. The presence of a sulfide mineral, such as pyrite, was found to increase the wear rate significantly, possibly due to galvanic interactions. It was also found that the wear rate is significantly higher than the sum of abrasive wear and the corrosive wear, due to a synergistic effect.

Similar content being viewed by others

References

Abuzriba, M.B., Dodd, R.A., Worzala, F.J., and Conrad, J.R., 1992, “Wear corrosion: Separation of the components of corrosion and wear,” Technical note, Corrosion, Vol. 48, pp. 2–4.

Adam, K., Natarajan, K.A.,and Iwasaki, I., 1984, “Grinding media wear and its effect on the flotation of sulfide minerals,” International Journal of Mineral Processing, Vol. 12, pp. 39–54.

Adam, K., Natarajan, K.A., Reimer, S.C., and Iwasaki, I., 1986, “Electrochemical aspects of grinding media-mineral interaction in sulfide ore grinding, Corrosion-NACE, Vol. 14, No 8, pp. 440–447.

Bond, F.C., 1964, “Metal wear in crushing and grinding,” Chem. Eng. Prog., Vol. 60, pp. 90–100.

Clark, H. Mcl., 1990, “Slurry erosion,” Proceedings of conference on corrosion-erosion wear of material at elevated temperatures, Electric Power Research Institute. NACE, January.

Dunn, D.J., 1985, “Metal removal mechanisms comprising wear in mineral processing,” Wear of Materials 1985, K.C. Ludema, ed., Am. Soc. Mech. Engr., New York. pp. 501–508.

Iwasaki, I., Reimer, S.C., Orlich, J.N., and Natarajan, K.A., 1985, “Corrosive and abrasive wear in ore grinding, Wear, Vol. 103, pp. 253–267.

Jackson, L.D.A., 1967, “Slurry abrasion,” Transactions of the Canadian Institute of Mining and Metallurgy, Vol. 70, pp. 219–224.

Jang, J.W., Iwasaki, I., and Moore, J.J., 1989, “The effect of galvanic interaction between martensite and ferrite in grinding media wear.” Corrosion, Vol. 45(5), pp. 402–407.

Klimpel, R., 1982/1983, “Slurry rheology influence on the performance of mineral/coal grinding circuits,” Mining Engineering, Part 1: Vol. 34, 1982, pp. 1665–1672; Part 2: Vol. 35, 1983, pp. 21–26.

Kotlyar, D., Pitt, C.H., and Wadsworth, M.E., 1987, “Simultaneous corrosion and abrasion measurements under grinding conditions, Corrosion-NACE, Vol. 44, No. 4, pp. 221–227.

Madsen, B., 1987, ASM Handbook, Friction, Lubrication and Wear Technology. Vol. 18, pp. 271–279.

Meloy, T.P., and Crabtree, D., 1967, “Surface tension and viscosity in wet grinding,” Proceedings II of the European Symposium on Comminution, Amsterdam, in DECHEM-Monogr., 57, pp. 405–426.

Natarajan, K.A., and Iwasaki, I., 1984, “Electrochemical aspects of grinding media-mineral interactions in magnetite ore grinding.” International Journal of Mineral Processing, Vol. 13, pp. 53–71.

National Materials Advisory Board, 1981, “Comminution and Energy Consumption.” Report of the Committee on Comminution and Energy Consumption, Publication NMAB-364, National Academy Press, Washington, D.C.

Postlethwaite, J., 1987, “The control of erosion in slurry pipelines,” Materials Performance, December, pp. 41–45.

Pozzo, R.L., and Iwasaki, I., 1987, “Effect of pyrite and pyrrhotite on the corrosive wear of grinding media,” Minerals and Metallurgical Processing, August, pp. 166–171.

Pozzo, R.L., and Iwasaki, I., 1989, “Pyrite-pyrrhotite grinding media interactions and their effects on media wear and flotation,” Journal of Electrochemical Society. Vol. 136. No. 6. pp. 1734–1739.

Rao, M.K.Y., and Natarajan, K.A., 1988, “Effect of electrochemical interactions among sulfide minerals and grinding medium on chalcopyrite flotation. Minerals and Metallurgical Processing, Vol. 6, No. 3, pp. 146–151.

Rao, S.R., Moon, K.S., and leja, J., 1976. “Effect of grinding media on the surface reactions and flotation of heavy metal sulfides,” M.C. Fuerstenau, ed., Flotation, A.M. Gaudin Memorial Volume, p. 509.

Remark, J.F., and Wick, O.J., 1976, “Corrosion control in ball and rod mills.” Corrosion-76, Houston, TX, Paper 121.

Author information

Authors and Affiliations

Additional information

Preprint 96-165, presented at the SME Annual Meeting, March 11–14, 1996, Phoenix, AZ.

M&MP paper 96-646. Discussion of this peer-reviewed and approved paper is invited and must be submitted to SME prior to Feb. 28, 1998.

Rights and permissions

About this article

Cite this article

Pazhianur, R., Adel, G.T., Yoon, R.H. et al. Cathodic protection to minimize corrosive wear in ball mills. Mining, Metallurgy & Exploration 14, 1–7 (1997). https://doi.org/10.1007/BF03402771

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03402771