Abstract

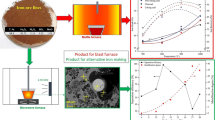

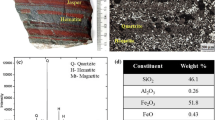

Microwave heating of iron ore was investigated as an alternative to conventional reduction processes to solve the problem of slow heat transfer. Microwave heating and reduction tests were run on composite green balls made from coal and magnetite concentrate. Bench-scale tests were run on both powdered and pelletized feeds using a 15 kW microwave generator. A significant increase in the reduction rate was obtained. With 20% excess stoichiometric carbon in the mix, more than 90% reduction of the iron ore can be achieved in about 10 min at temperatures of around 1,000 °C. The reduction of iron ore with coal by microwave heating produces a pure, dust-free, high-Btu flue gas that can be used in related thermal operations. Depending on the purity, the reduced iron product could be fed directly to an electric arc furnace for melting. In some cases, the removal of a slag phase may be required to eliminate excess silica and alumina.

Similar content being viewed by others

References

Atomic Energy of Canada Limited Research Company and Voss Associates Engineering Ltd., 1990, Microwaves and Minerals, Ontario Ministry of Northern Development and Mines.

Hepworth, M.T., and Zhong, S., 1991, “Thermodynamic comparison of lime as adesulfurizer with iron in coal combustion atmospheres”, Energy & Fuels, 5, pp. 237–243.

Lepinski, J.A., 1993, “Development of the FASTMET Direct Reduction Process,” SME preprint 93-66, SME Annual Meeting, Feb. 15–18, Reno, Nevada.

McGill, S.L., Walkiewicz, J.W., and Clark, A.E., 1995, “Microwave Heating of Chemicals and Minerals,” US Bureau of Mines, Report of Investigation, RI 9518.

Metaxas, A.C., and Meredith, R.J., 1983, Industrial Microwave Heating, Peter Peregrines Ltd., London.

Midrex Direct Reduction Corporation, 1996, “Worldwide DRI/HBI Production Exceeds 30 Million Tons,” Skillings Mining Review, Vol. 85, No. 10.

Seaton, S.E., Foster, J.S., and Velasco, J., 1983, “Reduction kinetics of hematite and magnetite pellets containing coal char,” Transactions ISIJ, 23, pp. 490–496.

Standish, N., and Worner, H., 1991, “Microwave application in the reduction of metal oxides with carbon, I&SM, May, pp. 59–61.

Tait, K.M., and McDonald, M.M., 1994, “Recent developments in IGCC technology,” CIM Bulletin, 87, 6, pp. 27–35.

Wilson, W.G., and McLean, A., 1980, Desulfurization of Iron and Steel and Sulfide Shape Control, The Iron & Steel Society of AIME, Warrendale, PA.

Author information

Authors and Affiliations

Additional information

SME paper 96–624, presented at the 69th Annual Meeting of the Minnesota Section of the SME, April 23–25, 1996, Duluth, MN. Discussion of this peer-reviewed and approved paper is invited and must be submitted, in duplicate, prior to Feb. 28, 1997.

Rights and permissions

About this article

Cite this article

Zhong, S., Geotzman, H.E. & Bleifuss, R.L. Reduction of iron ore with coal by microwave heating. Mining, Metallurgy & Exploration 13, 174–178 (1996). https://doi.org/10.1007/BF03402742

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03402742