Abstract

The major cost in comminution is energy consumption, which can be as high as 50% of the operating cost. Improvements in plant operations have resulted in up to a 15% reduction in energy usage (kw-hr/t). These improvements have been made through the optimization of grinding efficiency and the use of expert model-based control systems.

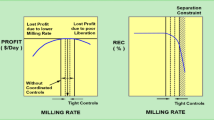

Optimization involves the determination of the levels of the critical-operating conditions that result in the most efficient breakage of ore in the mill. These optimal levels are identified through plant/laboratory test work and through computer simulation using advanced process models. Model-based expert control achieves the maximum performance from the grinding circuit by identifying the characteristics of the ore in the mill with an optimal on-line estimator. Using this information, the control system dynamically determines the operating point that will yield the optimal performance.

Two industrial applications of grinding-circuit optimization and model-based control are presented to demonstrate the power of this new technology.

Similar content being viewed by others

References

Lo, Y.C., Arbiter, N., Herbst, I.A., and Rajamani, K., 1988, “Design considerations tor large-diameter ball mills,” International Journal of Mineral Processing, Vol. 22, pp. 75–93.

Martinovic, T.I., Lo, Y.C., Ynchausti, R.A., and Herbst, J.A., 1990, “Steady state and dynamic optimization of ball milling at the carol pellet plant,” 7th European Symposium on Comminution, Part 2, pp. 713–728.

Author information

Authors and Affiliations

Additional information

SME Preprint 95–111, SME Annual Meeting, March 6–9, 1995, Denver, CO. M&MP paper 95–616. Discussion of the peer-reviewed and approved paper is invited and must be submitted, in duplicate, prior to May 31, 1996.

Rights and permissions

About this article

Cite this article

Lo, Y.C., Oblad, A.E. & Herbst, J.A. Cost reduction in grinding plants through process optimization and control. Mining, Metallurgy & Exploration 13, 19–21 (1996). https://doi.org/10.1007/BF03402711

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03402711