Summary

During the past century, advances in blast furnace design have been greatly infiuenced by improved burdens and increased demands for hot metal. This has resulted in increased hot blast temperatures and better material preparation, accompanied by increased iron rates and decreased coke rates.

However, with the trend towards fewer but larger furnaces, it is essential to consider all possible methods for lengthening furnace campaigns and for minimizing capital and operating costs.

Experience in the design of blast furnaces, combined with a thorough study of current operating practices, leads to the following conclusions:

1. Longer blast furnace campaigns and maximum benefits from the use of modern burdens are possible by means of better refractories, more effective cooling, and careful attention to details of design and supervision of construction.

2. For a given ironmaking requirement, it costs less to build and operate ablast furnace designed for about 12 psi top pressure and operated at about 6 psi, than one designed for substantially higher or lower top pressure.

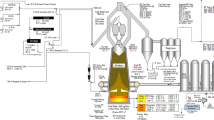

3) The greatest savings in blast furnace labor costs may be found in the cast house where the majority of manual labor is concentrated. The four-post furnace design permits maximum use of mechanized equipment to help realize these savings.

Similar content being viewed by others

References

K. R. Haley: Pellets Preferred, Blast Furnace and Steel Plant, May 1965, vol. 53, no. 5, pp. 393–397.

Yu. A. Popov and V. I. Markin: Wear of Blast-Furnace Carbon Hearth Pads, Stal (in English), Nov. 1959, pp. 811–813.

J. L. Brady, J. L. Pugh and R. W. Adams: Amanda and Bellefonte... Answers to Iron-making, Journal of Metals, Aug. 1964, vol. 16, no. 8, pp. 637–643.

W. E. Slagley and C. M. Squarcy: Peripheral Cooling of a Blast Furnace, Blast Furnace and Steel Plant, April 1965, vol. 53, no. 4, pp. 303–310.

M. J. Greaves: Application of Combustion Equipment to Blast Furnace Stoves, Iron and Steel Engineer, July 1963, vol. 40, no. 7, pp. 84–95.

M. J. Greaves: Belts vs. Skips for Filling a 4000-Ton Blast Furnace, Blast Furnace and Steel Plant, Aug. 1964, vol. 52, no. 8, pp. 685–691.

M. J. Greaves: Engineering a Cast House for a 4000-Ton Blast Furnace, AIME Iron-making Proceedings, 1964.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Greaves, M.J. The Effect of Modern Burdens on Blast Furnace Design. JOM 18, 378–384 (1966). https://doi.org/10.1007/BF03397507

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03397507