Conclusions

The R-H degassing plant was commissioned at Bilston in May 1965 with the prime purposes of: 1) Widening the range of specifications that could be made in the open hearth shop; 2) Up-grading steel quality generally to meet present and anticipated market requirements; and 3) Providing an additional control tool in steel plant, particularly regarding steel chemistry.

So far, some 200 heats have been treated, and promising results have been obtained in line with the above purposes.

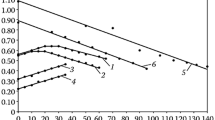

Degassing results in a 50% H removal, a similar reduction in oxygen, and some improvement in steel cleanness, particularly in the top portions of the ingot.

Beneficial effects, as measured by good product yield from degassing, have been noted on certain qualities but not on others, and further experience and work is required to be absolutely certain that the improvements in yield are directly attributable to the degassing process. Nevertheless, we are satisfied that the plant is a worthwhile investment in the future, and it is proving of real benefit in meeting the requirements of the Bilston market strategy.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Forster, G.B. R-H degassing. JOM 18, 628–633 (1966). https://doi.org/10.1007/BF03378448

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03378448