Abstract

The challenge of how to adequately characterize the toughness behavior of ductile cast iron (DCI) materials had been solved through the development and application of fracture mechanics concepts. Outstanding examples are found in the design and safety assessment procedures of sophisticated DCI components for wind turbines or transport and storage casks for radioactive materials. An essential requirement for these procedures is to have adequate fracture mechanics toughness data available.

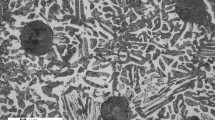

Because DCI materials may substantially change their deformation, damage and fracture behavior from ductile to brittle by increasing loading rate, decreasing temperature, increasing pearlite share and increasing stress triaxiality, the corresponding experimental measuring techniques and analysis concepts have to be chosen and adapted with deliberation. Long-time experience in this field is imperative to provide valuable data.

BAM has been dealing with mechanical and fracture mechanical characterization of DCI materials for more than 30 years. This paper demonstrates state-of-the-art fracture mechanics test methods for the determination of quasi-static and dynamic fracture toughness. Among others, it is exemplarily shown for a variety of DCI materials conforming to grade EN-GJS-400 how mechanical and fracture mechanical properties are influenced by temperature, loading rate and microstructure. A major lesson to be learned is that fracture toughness data of DCI should always be discussed, reported and used in correlation with microstructural parameters.

Similar content being viewed by others

References

Pusch, G., Bruchmechanische Sicherheitskonzepte und ihre Anwendung auf Gusseisenwerkstoffe, konstruieren + giessen 17 (1992) 3, pp. 29–35; 17 (1992) 4, pp. 4–12; 18 (1993) 1, pp. 4–11 as well as 18 (1993) 2, pp. 4–10.

Baer, W., Häcker, R., Werkstoffcharakterisierung von Gusseisenwerkstoffen mit Kugelgraphit — dynamische Zugversuche unter dem Aspekt der Bauteilsicherheitsbewertung, MP Materials Testing 47, 1–2, pp. 34–44 (2005).

SINTAP, Structural Integrity Assessment Procedure, Final Report, EU-Project BE 95-1462, Brussels: Brite Euram Programme (1999).

BAM-GGR 007, Leitlinie zur Verwendung von Gusseisen mit Kugelgraphit für Transport- und Lagerbehälter für radioaktive Stoffe, Rev. 0, BAM Berlin (June 2002).

ASME Code Case N-670, “Use of Ductile Cast Iron Conforming to ASTM A 874/A 874M-98 or JIS G 5504-1992 for Transport Containments,” ASME Section III, Division 3, BC01-810 (June 2005).

Guideline for the Certification of Wind Turbines, Germanischer Lloyd Industrial Services GmbH, Hamburg, edition (2010).

FKM-Richtlinie Bruchmechanischer Festigkeitsnachweis für Maschinenbauteile, Forschungskuratorium Maschinenbau, Frankfurt/Main, 3rd edition (2006).

DVS-Merkblatt 2401, Bruchmechanische Bewertung von Fehlern in Schweißverbindungen, DVS Verlag, Düsseldorf (2004).

ISO 12135, “Metallic materials — Unified method of test for the determination of quasistatic fracture toughness,” ISO, Switzerland (2002).

ASTM E1820, “Standard Test Method for Measurement of Fracture Toughness,” ASTM International, West Conshohocken, PA (2011).

ASTM E399, “Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness K Ic of Metallic Materials,” ASTM International, West Conshohocken, PA (2012).

ESIS P2, “Procedure for determining the fracture behavior of materials,” European Structural Integrity Society, Delft, The Netherlands (1992).

ISO/DIS 26843, “Metallic Materials — Measurement of fracture toughness at impact loading rates using precracked Charpy-type test pieces,” ISO, Switzerland (July 2012).

ASTM E2298, Standard Test Method for Instrumented Impact Testing of Metallic Materials, ASTM International, West Conshohocken, PA (2009).

ISO 14556 and Amendment 1, “Steel — Charpy V-notch pendulum impact test — Instrumented test method; Amendment 1: Annex D — Instrumented Charpy V-notch pendulum impact test of sub-size test pieces,” ISO Switzerland (2000 and 2006).

Baer, W., Experimentelle Ermittlung dynamischer Bruchzähigkeitswerte von ferritischem Gusseisen mit Kugelgraphit — Normung und aktuelle Datenbasis; Conference Werkstoffprüfung — Fortschritte der Kennwertermittlung für Forschung und Praxis, ed. H. Frenz and W. Grellmann, DVM publishers, Berlin, pp. 275–282 (2008).

ASTM E647, “Standard Test Method for Measurement of Fatigue Crack Growth Rates,” ASTM International, West Conshohocken, PA (2013).

ISO 12108, “Metallic materials — Fatigue testing — Fatigue crack growth method,” ISO, Switzerland, (2012).

Hübner, P., Schlosser, H., Pusch, G., Biermann, H., “Load history effects in ductile cast iron for wind turbine components,” Int. Journal of Fatigue, vol. 29, pp. 1788–1796 (2007).

Zybell, L., Chaves, H., Kuna, M., Mottitschka, T., Pusch, G., Biermann, H., “Optical in situ investigations of overload effects during fatigue crack growth in nodular cast iron,” Engineering Fracture Mechanics, vol. 95, pp. 45–56 (2012).

ISO 945-1, “Designation of microstructure of cast irons — Part 1: Graphite classification by visual analysis,” ISO, Switzerland (2008).

Velichko, A., Muecklich, F., “Shape Analysis and Classification of Irregular Graphite,” Prakt. Metallogr. 434, pp. 192–207 (2006).

Velichko, A., Holzapfel, C., Muecklich, F., 3D Characterization of Graphite Morphologies in Cast Iron, Advanced Engineering Materials 9 1–2, pp. 39–45 (2007).

Baer, W., Bösel, D., Eberle, D., Klingbeil, D., Development and application of a key curve-method for fracture mechanical material characterization of cast iron materials under dynamic loading, Final report on the German Science Foundation research projects BA 1913/2-1 and BA 1913/2-2 (in German), BAM Berlin, (2009).

Baer, W., Bruchmechanische Bewertung ferritischer Gusseisenwerkstoffe sowie artgleicher Schweißverbindungen bei statischer Beanspruchung, PhD Thesis, Freiberg University of Mining and Technology, (1996).

Baer, W., Wossidlo, P., Abbasi, B., Cassau, M., Häcker, R., Kossert, R., “Large scale testing and statistical analysis of dynamic fracture toughness of ductile cast iron,” Engineering Fracture Mechanics 768, pp. 1074–1086 (2009).

Stroppe, H., Pusch, G., Ludwig, A., Bestimmung der Bruchzähigkeit von ferritischem Gusseisen mit Kugelgraphit aus Kennwerten des Zugversuchs und der Gefügeausbildung, Gießereiforschung 544, pp. 115–120 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baer, W. Advanced Fracture Mechanics Testing of DCI — A Key to Valuable Toughness Data. Inter Metalcast 8, 25–34 (2014). https://doi.org/10.1007/BF03355579

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355579