Abstract

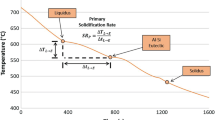

The Al-20%Si melt heated to 785°C (1445°F) and 850°C (1562°F) exhibited refinement of the primary Si while heating to 735°C (1355°F) produced coarse and heterogeneous primary Si crystals following the solidification process at approximately 1.3, 4.5, 15 and 35°C/s. The primary Si crystals were 40% finer for the samples heated to 850°C (1562°F) as compared with those heated to 735°C (1355°F). Higher cooling rates produced better primary Si refinement and minimized its variation caused by the melt temperature. The secondary dendrite arm spacing (SDAS) was not affected by the melt temperature and was a function of the cooling rate for the given experimental conditions. The SDAS changed from approximately 32 to 22μm for a 1.3 and 4.5°C/s cooling rate and was reduced to approximately 11μm for a 35°C/s cooling rate. Cooling curve analysis was used to analyze the sequence of the metallurgical transformations and fraction liquid development during alloy melting and solidification. The non-equilibrium thermal characteristics under cooling rate up to 15°C/s were analyzed as well. The experimental results were used to optimize the casting process and improve the service characteristics of the vacuum assisted high pressure die casting (HPDC) motorcycle engine blocks.

Similar content being viewed by others

References

Ghosh S., Mott W.J., “Some Aspects of Refinement of Hypereutectic Al-Si Alloys”, AFS Transactions, vol. 72, pp 721–732 (1964).

Henslar P., “The New Porsche 944 4-Cylinder Aluminum Engine”, SAE Paper No. 830004 (1983).

Jorstad J.L., “Reynolds 390 Engine Technology” SAE Paper No. 830010 (1983).

Legge R. A., Smith D. M., Henkel G., “Improved Aluminium Alloy for Engine Applications”, SAE Paper No. 860558 (1986).

Reuss L.E., Hughes C. N., SAE Paper No. 710150 (1971).

Yamagata H., Kasprzak W., Aniolek M., Kurita H., Sokolowski J.H., “The Effect of Average Cooling Rates on the Microstructure of the Al-20% Si High Pressure Die Casting Alloy used for Monolithic Cylinder Blocks”, Journal of Materials Processing Technology, vol. 203, pp 333–341 (2008).

Yamagata H., Kurita H., Aniolek M., Kasprzak W., Sokolowski J.H., “Thermal and Metallographic Characteristics of the Al-20% Si High-Pressure Die-Casting Alloy for Monolithic Cylinder Blocks”, Journal of Materials Processing Technology, vol. 199, no. 1–3, pp 84–90 (2008).

Tenekedjiev N., Gruzleski J.E., “Hypereutectic Aluminum-Silicon Casting Alloys — A Review”, Cast Metals, vol. 3, no. 2, pp 96–105 (1990).

Yamagata H., “The Science and Technology of Materials in Automotive Engines”, Woodhead Publishing, Cambridge, (2005).

Kamble S., Ravindran C., “Analysis of Primary Silicon Crystals in Hypereutectic Aluminum-Silicon Alloys: Effect of Change in Process Parameters”, AFS Transactions, vol. 113, pp 87–97 (2005).

Kim M., “Electron Back Scattering Diffraction (EBSD) Analysis of Hypereutectic Al-Si Alloys Modified by Sr and Sc”, Metals and Materials International, vol. 13, no. 2, pp 103–107 (2007).

Li J., Elmadagli M., Gertsman V.Y., Lo J., Alpas A.T., “FIB and TEM Characterization of Subsurfaces of an Al-Si Alloy (A390) Subjected to Sliding Wear”, Materials Science and Engineering A, vol. 421, no. 1–2, pp 317–327 (2006).

Xu C.L., Yang Y.F., Wang H.Y., Jiang Q.C., “Effects of Modification and Heat Treatment on the Abrasive Wear Behavior of Hypereutectic Al-Si Alloys”, Journal of Materials Science, vol. 42, no. 15, pp 6331–6338 (2007).

Djurdjevic M. B., Kasprzak W., Kierkus C.A., Kierkus W.T., Sokolowski J.H., “Quantification of Cu Enriched Phases in Synthetic 3XX Aluminum Alloys using the Thermal Analysis Technique”, AFS Transactions, vol. 16, pp 1–12 (2001).

Yamagata, H., Kurita, H., “Effect of Elastic Deformation of the Honing Stone on the Exposure of Si-Crystals in a Hyper-Eutectic-Si Aluminum Cylinder Block”, Society of Automotive Engineers of Japan. SAE Paper No. 20056577 (2005).

Donaule R.J., Hesterberg W.G., Cleary T.M., “Hypereutectic Aluminum-Silicon Alloy Having Refined Primary Silicon and a Modified Eutectic”, U.S. Patent No. 5234514 (Aug. 1992).

Eady J.A., Smith D.M., “Properties and Applications of New Aluminum Foundry Alloy”, SAE Paper No. 840123 (1984).

Shamsuzzoha M., Juretzko F.R., “Dual Refinement of Primary and Eutectic Silicon in Hyper-Eutectic Al-Si Alloys”, Aluminum Alloys for Transportation, Packaging, Aerospace and Other Applications, pp 153–162 (2007).

Wang R-Y., Lu W-H., Ma Z-Y., “Electrolytic Hypereutectic Alloy Casting with Completely Eutectic Structure”, AFS Transactions, vol. 115, pp 241–248 (2007).

Xiufang B., Weimin W., “Thermal-Rate Treatment and Structure Transformation of Al-13 wt% Si Alloy Melt”, Materials Letters, (44) 1 54–58 (2000).

Sigworth G. K., “Refinement of Hypereutectic Al-Si Alloys”, AFS Transactions, vol. 95, pp 303–314 (1987).

Wang H., Ning Z.Z., Davidson C.J., St John D.H., Xie S.S., “Thixotropic Structure Formation in A390 Hypereutectic Al-Si Alloy”, Proceedings of the 8th International Conference of Semi-Solid Processing, Limassol, Cyprus, Worcester Polytechnic Institute (2004).

Kasprzak M., Kasprzak W., Sokolowski J. H., U. S. Patent No. 7,255,828 (Aug. 14, 2007).

Dehong L., Yehua J., Guisheng G., Rongfeng Z., Zhenhua L., Rong Z., “Refinement of Primary Si in Hypereutectic Al-Si Alloy by Electromagnetic Stirring”, Journal of Materials Processing Technology, vol. 189(1–3) pp 13–18 (2007).

Takagi H., Uetani Y., Dohi M., Yamashita T., Matsuda K., Ikeno S., “Effects of Mechanical Stirring and Vibration on the Microstructure of Hypereutectic Al-Si-Cu-Mg Alloy Billets”, Materials Transactions, vol. 48, no. 5, pp 960–966 (2007).

Youn J. IL., Kang B. II, Kim Y. J., “Ultrasonic Injection for Melts Modification of Hyper-eutectic Aluminum Alloy”, Asian Forum of Light Metals & Exhibition. Kaohsiung, Taiwan (2007).

Kurita H., Yamagata H., “Hypereutectic Al-20%Si Alloy Engine Block using High-Pressure Die-Casting”, Proceedings of the SAE 2004 World Congress & Exhibition, Detroit, USA, 2004-01-1028 (2004).

Chen X., Kasprzak W., Sokolowski J. H., “Reduction of the Heat Treatment Process for Al-based Alloys by Utilization of Heat from the Solidification Process”, Journal of Materials Processing Technology, vol. 176, no. 1–3, pp 24–31 (2006).

Kasprzak M., Kasprzak W., Kierkus C.A, Kierkus W.T., Sokolowski J.H., Evans W. J., “Structure and Matrix Microhardness of the 319 Aluminum Alloy After Isothermal Holding During the Solidification Process”, AFS Transactions, vol. 16, pp 1–11 (2001).

Sokolowski J.H., Kierkus W.T., Kasprzak M., Kasprzak W., U.S. Patent No. 7,354,491 (April 8, 2008).

Onda H., Sakurai K., Masuta T., Oikawa K., Anzai K., Kasprzak W., Sokolowski J. H., “The Effect of Solidification Models on the Prediction Results of the Temperature Change of the Aluminum Cylinder Head Estimated by FDM Solidification Analysis”, Trans Tech Publications, Switzerland, Materials Science Forum, 561–565 1967–1970 (2007).

Jorstad J.L., Apelian D., “Hypereutectic Al-Si Alloys: Practical Processing Techniques”, Die Casting Engineer, vol. 48, no. 3, pp 50, 52, 54–56, 58 (2004).

Backerüd L., Chai G., Tamminen J., “Solidification Characteristics of Aluminum Alloys, Vol. 2. Foundry Alloys”, American Foundry Society Inc., Stockholm, (1990).

Jorstad J.L., Apelian D., “Pressure Assisted Processes for High Integrity Aluminum Castings”, International Journal of Metalcasting, vol. 2, no. 1, pp 19–39 (2008).

Jernkontoret Stockholm, “A Guide to the Solidification of Steels”, pp 162, ISBN 91-7260-156-6 (1977).

Eskin G.I., Eskin D.G., “Some Control Mechanism of Spatial Solidification in Light Alloys”, Zeitschrift fur Metallkunde, vol. 95, no. 8 (2004).

Telang Y.P., “Process Variables in Al-21Si Alloys Refinement”, AFS Transactions, vol. 71, pp 232–240 (1963).

Weiss J.C., Loper Jr. C.R., “Primary Si in Hypereutectic Aluminum-Silicon Castings”, AFS Transactions, vol. 95, pp 51–62 (1987).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kasprzak, W., Sahoo, M., Sokolowski, J. et al. The Effect of the Melt Temperature and the Cooling Rate on the Microstructure of the Al-20% Si Alloy Used for Monolithic Engine Blocks. Inter Metalcast 3, 55–71 (2009). https://doi.org/10.1007/BF03355453

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355453