Abstract

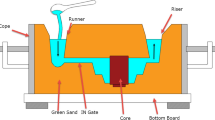

The quality of castings produced by green sand moulds depends strongly on the compaction of the moulding sand. The moulding process parameters of green sand directly affect casting quality, energy consumption and cycle time. Unnecessary holding periods during particular compaction process steps increase the cycle time and also cause higher energy consumption. The determination of optimal compaction parameters is often carried out by trial-and-error which is expensive and time consuming. To improve this situation, the process of compaction is calculated using a mathematical model and the finite element method (FEM). For the validation of the calculated and experimental data the computer tomography method was used. The effect of different moulding parameters was examined using a new sensor. During mould compaction the sand density in different regions of the mould was recorded over time. These results allow foundry personnel to monitor, adjust and optimise the moulding process.

Similar content being viewed by others

References

Flemming, E., Tilch W., Formstoffe und Formverfahren, p. 448, Deutscher Verlag für Grundstoffindustrie (1993).

Bast, J., Malaschkin, A., Kadauw, A., Gießerei 2005, 8, p. 23–27 (2005).

Tilch, W., Gießerei-Praxis 2004, 2, 53–62 (2004).

Kadauw, A., Bast, J., Aydogmus, T., Statusbericht des Instituts für Geotechnik der TU Bergakademie Freiberg, 2006, p. 259–267 (2006).

Zhou, F., No. 31, RWTH Aachen, 1997, p. 244 (1997).

Brinkgreve, R., Plaxis, B., “Plaxis catalogue version 7, Part 3: Material Models Manual,” 1-1–4-11, 1998 Netherlands (1998).

Makino, H., Maeda, Y., Nomura, H., “CIATF Technical Forum Düsseldorf, 1999,” p. 144–151 (1999).

Cundall, P. A., “Proceedings of the Symposium of the International Society of Rock Mechanics,” France, 1971 Paper II-8 (1971).

Yifei, Z., Junjiao, W., Transactions of the American Foundry Society 2003, 3, 1–4 (2003).

Kadauw, A., Bast, J., Fiedler, D., Betchvaia, I., Saewert, H.C., “Computer Simulation of Squeeze Moulding and Validation of Results using Industrial Computer Tomography (ICT),” Archives of Metallurgy and Materials, ISSN 1733-490, Vol. 52, 3/2007 Polen (2007).

DISA Industrie AG; Bast J. and Malaschkin, Andrej, “Sensor zur Messung der von der Sandbewegung hervorgerufenen Kraft während der Verdichtung tongebundener Formstoffe bei der Herstellung von Gießformen,” Europäisches Patentamt, 22.02.2003, Aktenzeichen: 03706557.0-2122-EP0301820 (2003).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bast, J., Kadauw, A. & Malaschkin, A. Optimising of Moulding Parameters for Green Sand Compaction by Computer Simulation and a New Compaction Measuring Device. Inter Metalcast 3, 55–65 (2009). https://doi.org/10.1007/BF03355448

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355448