Abstract

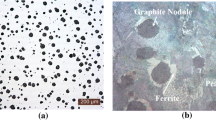

Dilatometry has been extensively used to study the transformation behavior of steels. This paper outlines the use of Gleeble dilatometry to characterize the transformation kinetics and ferrite-pearlite ratios in a 65-45-12 ductile iron. Samples were heated to 900°C (1650°F) and cooled at constant cooling rates ranging from 2 to 2000°C/min (3.6 to 3600°Flmin). The dilatometer results were analyzed and transformation temperatures and the ferrite-pearlite ratio in the final microstructure were determined. The information was also used to estimate the continuous-cooling-transformation (CCT) curve for 65-45-12 ductile iron. The agreement between the ferrite-pearlite ratio predicted from the dilatometry results and metallographic analysis of dilatometry specimens was excellent.

Similar content being viewed by others

References

Hughes, T.C.H., “Ductile Iron,” ASM Handbook, Volume 15, Casting, pp. 647–666 (1988)

Rundman, K.B., “Heat Treating of Ductile Irons,” ASM Handbook, Volume 4, Heat Treating, pp. 682–692 (1991).

Gomez, M., Medina, S.F. and Caruana, G., “Modelling of Phase Transformation Kinetics by Correction of Dilatometry Results for a Ferritic Nb-microalloyed Steel’” ISIJ International, Vol. 43, pp. 1228–37 (2003).

Kop, T.A., Sietsma, J. and Zwaag, S.V.D., “Dilatometric Analysis of Phase Transformations in Hypo-eutectoid Steels”, Journal of Materials Science, Vol. 36, pp. 519–26 (2001).

Prior, G.K., “The Role of Dilatometry in the Characterization of Steels”, Materials Forum, Vol. 18, pp. 265–76 (1994).

Terziev, L., Lecomtre-Beckers, J., Bojinov, V., Petrov, R. and Breyer, J. P., “Dilatometric and Calorimetric Study of the Graphitisation of High Chromium Cast Iron,” J. Chim. Phys., vol. 94, pp. 1107–1115 (1997).

Mrvar, P., Trbizan, M. and Jozef Medved., “Dilatation analysis of the eutectoid transformation of the as-cast spheroidal graphite cast iron,” Scandinavian Journal of Metallurgy, vol. 31, pp. 393–400 (2002).

Ahmadabadi, M.N. and Farjami, S., “Transformation Kinetics of Unalloyed and High Mn Austempered Ductile Iron”, Material Science and technology, Vol. 19, pp. 645–9 (2003).

Ivanova, R., Sha, W. and Malinov, S., “Differential Scanning Calorimetry and Microscopy Study of Transformation in Ductile Cast Irons: Part II. Continous Cooling,” ISIJ International, vol. 44, pp. 896–904 (2004).

Zimba, J., Simbi, D. J., Chandra, T. and Navara, E., “A Dilatometry Study of the Austenization and Cooling Behavior of Ductile Iron Meant for the Production of Austempered Ductile Iron (ADI),” Materials and Manufacturing Processes, vol. 19, pp. 907–920 (2004).

Balloy, D. and Tissier, J.-C., “Improvement in the characteristics of nodular graphite cast iron for crankshafts,” Steel Research International, vol. 78, pp. 167–172 (2007).

Buddy Damm, E. and Lasday, S.B., “Metallurgical Physical Simulation System and Examples of Practical Applications,” Industrial Heating, vol. 63, pp. 23–29 (1996).

ASTM A 1033-04, “Standard Practice for Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformation”, ASTM International, pp. 1–14 (2004).

Samuel, C. and Viswanathan, S., “Specimen Configurations for Gleeble Dilatometry”, Poster Presentation, The Minerals, Metals, and Materials Society Annual Meeting. New Orleans, March 10–13, 2008.

Mespoint, C., Zhao, J.Z., Vandeputte, S. and Cooman, B.C.D., “An Improved Method for Determining the Continuous Cooling Transformation Diagram of C-Mn Steels”, Steel Research, Vol. 72, pp. 263–70 (2001).

Venugoplan, D.A., “Kinetic Model of the γ−α + Gr Eutectoid Transformation in Spheroidal Graphite Cast Irons,” Metallurgical Transactions A, vol. 21A, pp. 913–918 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Samuel, C., Viswanathan, S. Transformation Kinetics and Ferrite-Pearlite Ratios in a 65-45-12 Ductile Iron. Inter Metalcast 2, 55–65 (2008). https://doi.org/10.1007/BF03355436

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355436