Abstract

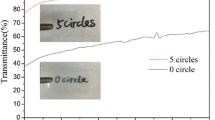

The goal of this work is to produce nanocomposite film with low oxygen permeability by casting an aqueous solution containing xylan, sorbitol and nanocrystalline cellulose. The morphology of the resulting nanocomposite films was examined by scanning electron microscopy and atomic force microscopy which showed that control films containing xylan and sorbitol had a more open structure as compared to xylan-sorbitol films containing sulfonated nanocrystalline cellulose. The average pore diameter, bulk density, porosity and tortuosity factor measurements of control xylan films and nanocomposite xylan films were examined by mercury intrusion porosimetry techniques. Xylan films reinforced with nanocrystalline cellulose were denser and exhibited higher tortuosity factor than the control xylan films. Control xylan films had average pore diameter, bulk density, porosity and tortuosity factor of 0.1730 µm, 0.6165 g/ml, 53.0161% and 1.258, respectively as compared to xylan films reinforced with 50% nanocrystalline cellulose with average pore diameter of 0.0581 µm, bulk density of 1.1513 g/ml, porosity of 22.8906% and tortuosity factor of 2.005. Oxygen transmission rate tests demonstrated that films prepared with xylan, sorbitol and 5%, 10%, 25% and 50% sulfonated nanocrystalline cellulose exhibited a significantly reduced oxygen permeability of 1.1387, 1.0933, 0.8986 and 0.1799 cm3·µm/m2·d·kPa respectively with respect to films prepared solely from xylan and sorbitol with a oxygen permeability of 189.1665 cm3·µm/m2·d·kPa. These properties suggested these nanocomposite films have promising barrier properties.

Article PDF

Similar content being viewed by others

References

L. Shen, E. Worrell and M. Patel, Biofuels, Bioprod. Biorefin. 4, 25 (2010). doi:10.1002/bbb.189

A. Samir, F. Alloin and A. Dufresne, Biomacromolecules 6, 612 (2005).

A. J. Ragauskas, C. K. Williams, B. H. Davison, G. Britovsek, J. Cairney, C. A. Eckert, W. J. Frederick, J. P. Hallett, D. J. Leak, C. L. Liotta, J. R. Mielenz, R. Murphy, R. Templer and T. Tschaplinski, Science 311, 484 (2006). doi:10.1126/science.1114736

L. Petersson and K. Oksman, Compos. Sci. Technol. 66, 2187 (2006). doi:10.1016/j.compscitech.2005.12.010

J. M. Krochta, E. A. Baldwin and M. O. Nisperos-Carriedo, Lancaster: Technomic (1994).

J. Hartman, A. C. Albertsson, M. S. Lindblad and J. Sjöberg, J. Appl. Polym. Sci. 100, 2985 (2006). doi:10.1002/app.22958

M. Gröndahl, L. Eriksson and P. Gatenholm, Biomacromolecules 5, 1528 (2004). doi:10.1021/bm049925n

P. Dole, C. Joly, E. Espuche, I. Alric and N. Gontard, Carbohydr. Polym. 58, 335 (2004). doi:10.1016/j.carbpol.2004.08.002

B. L. Butler, P. J. Vergano, R. F. Testin, J. M. Bunn and J. L. Wiles, J. Food Sci. 61, 953 (1996). doi:10.1111/j.1365-2621.1996.tb10909.x

I. Arvanitoyannis and C. G. Biliaderis, Carbohydr. Polym. 38, 47 (1999). doi:10.1016/S0144-8617(98)00087-3

A. W. Rindlav, M. Stading, A. M. Hermansson and P. Gatenholm, Carbohydr. Polym. 36, 217 (1998). doi:10.1016/S0144-8617(98)00025-3

P. Linder, R. Bergman, A. Bodin and P. Gatenholm, Langmuir 19, 5072 (2003). doi:10.1021/la0341355

K. S. Mikkonen, S. Heikkinen, A. Soovre, M. Peura, R. Serimaa, R. A. Talja, J. Appl. Polym. Sci. 114, 457 (2009). doi:10.1002/app.30513

U. Edlund, Y. Z. Ryberg and A. C. Albertsson, Biomacromolecules 11, 2532 (2010). doi:10.1021/bm100767g

M. A. S. A, Samir, F. Alloin and A. Dufresne, Biomacromolecules 6, 612 (2005).

Kvien, J. Sugiyama, M. Votrubec and K. Oksman, J Mater. Sci. 42, 8163 (2007). doi:10.1007/s10853-007-1699-2

L. Petersson, I. Kvien and K. Oksman, Composites Sci. Technol. 67, 2535 (2007). doi:10.1016/j.compscitech.2006. 12.012

X. D. Cao, H. Dong and C. M. Li, Biomacromolecules 8, 899 (2007). doi:10.1021/bm0610368

S. Harbaugh, N. K. Loughnane, M. Davidson, L. Narayanan, S. Trott, Y. G. Chushak and M. O. Stone, Biomacromolecules 6, 1055 (2005). doi:10.1021/bm049291k

M. Lagaron, R. Catala and R. Gavaa, Mater. Sci. Technol. 20, 1 (2004). doi:10.1179/026708304225010442

M. M. De Souza Lima and R. Borsali, Macromol. Rapid. Commun. 25, 771 (2004). doi:10.1002/marc.200300268

M. Ioelovich, BioRes. 3, 1403 (2008).

S. Mikkonen, A. P. Mathew, K. Pirkkalainen, R. Serimaa, C. Xu, S. Willför, K. Oksman and M. Tenkanen, Cellulose 17, 69 (2009). doi:10.1007/s10570-009-9380-3

S. Mikkonen, M. I. Heikkilä, H. Helén, L. Hyvönen and M. Tenkanen, Carbohydr. Polym. 79, 1107 (2010). doi:10.1016/j.carbpol.2009.10.049

P. Coughlan and G. P. Hazlewood, Hemicellulose and Hemicellulases (Eds). Portland Press Ltd, NC, U.S.A 1993.

A. Ebringerova and T. Heinze, Macromol. Rapid Commun. 21, 542 (2000). doi:10.1002/1521-3927(20000601)21:9<542::AID-MARC542>3.0.CO;2-7

I. Gabrielli and P. Gatenholm, J. Appl. Polym. Sci. 69, 1661 (1998). doi:10.1002/(SICI)1097-4628(19980822)69:8<1661::AID-APP19>3.0.CO;2-X

A. Saxena, T. Elder, P. Shaobo and A. J. Ragauskas, Composites Part B: 40, 8 (2009).

A. Saxena and A. J. Ragauskas, Carbohydr. Polym. 78, 357 (2009). doi:10.1016/j.carbpol.2009.03.039

Y. Pu, J. Zhang, T. Elder, Y. Deng, P. Gatenholm and A. J. Ragauskas, Composites Part B: Eng. 38, 360 (2007). doi:10.1016/j.compositesb.2006.07.008

S. Katz, R. P. Beatson and A. M. Scallan, Sven. Papperstidn 87, 48 (1984).

ASTM, Standard test method for oxygen transmission rate through plastic film and sheeting using a coulometric sensor, designation D 3985-9, in: Annual Book of ASTM Standards, American Society for Testing and Materials, 1995.

R. T. Parry, Principles and applications of modified atmosphere packaging of foods, Blackie Academic & Professional, England, 1 (1993).

Syverud and P. Stenius, Cellulose 16, 75 (2009). doi:10.1007/s10570-008-9244-2

A. Ebringerova and T. Heinze, Macromol. Rapid Commun. 21, 542 (2000). doi:10.1002/1521-3927(20000601)21:9<542::AID-MARC542>3.0.CO;2-7

I. Gabrielli and P. Gatenholm, J. Appl. Polym. Sci. 69, 1661 (1998). doi:10.1002/(SICI)1097-4628(19980822)69:8<1661::AID-APP19>3.0.CO;2-X

A. Saxena, T. Elder, P. Shaobo and A. J. Ragauskas, Composites Part B: 40, 8 (2009).

A. Saxena and A. J. Ragauskas, Carbohydr. Polym. 78, 357 (2009). doi:10.1016/j.carbpol.2009.03.039

Y. Pu, J. Zhang, T. Elder, Y. Deng, P. Gatenholm and A. J. Ragauskas, Composites Part B: Engineering 38, 360 (2007). doi:10.1016/j.compositesb.2006.07.008

S. Katz, R. P. Beatson and A. M. Scallan, Sven. Papperstidn 87, 48 (1984).

ASTM, Standard test method for oxygen transmission rate through plastic film and sheeting using a coulometric sensor, designation D 3985-9, in: Annual Book of ASTM Standards, American Society for Testing and Materials, 1995.

R. T. Parry, Principles and applications of modified atmosphere packaging of foods. Blackie Academic & Professional, England, 1 (1993).

Syverud and P. Stenius, Cellulose 16, 75 (2009). doi:10.1007/s10570-008-9244-2

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saxena, A., Elder, T.J., Kenvin, J. et al. High Oxygen Nanocomposite Barrier Films Based on Xylan and Nanocrystalline Cellulose. Nano-Micro Lett. 2, 235–241 (2010). https://doi.org/10.1007/BF03353849

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03353849