Summary

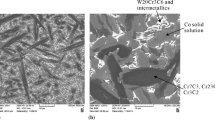

Cobalt-base alloys have enjoyed extensive use in wear-related engineering applications for well over 50 years because of their inherent high-strength, corrosion resistance, and ability to retain hardness at elevated temperatures. Microstructurally, wear-resistant cobalt-base alloys consist of hard particles (Cr7C3) dispersed in cobalt-rich (Co > 50%) solid solution matrix alloys (generally Co-Cr-W/Mo). Recent investigations in the Cabot Corporation Technology Laboratories have shown that the adhesive and cavitation-erosion wear characteristics of these alloys are determined by the composition of the matrix alloy and are influenced to a large extent by a strain-induce fee → hep allotropie transformation in the matrix alloy. Further, it has been shown that the cobalt content in the matrix alloy can be decreased to approximately 30% without significantly degrading relevant wear or corrosion properties. Toughness and abrasive wear resistance, on the other hand, are determined primarily by carbide volume fraction and morphology. Large, hypereutectic carbides are generally preferred for good abrasive wear resistance but are detrimental to toughness considerations. The tribological measurements and microstructural correlations associated with these Cabot investigations are summarized and discussed in this paper.

Similar content being viewed by others

References

R.D. Gray, “A History of the Haynes Stellite Company,” Cabot Corporation, 1974.

W.L. Silence, “Effect of Structure on Wear Resistance of Co-, Fe, and Ni-base Alloys,” Wear of Materials 1977, ASME, 1977.

J. Westbrook, Journal of Metals, 9, 1957.

Giamei, J. Burma, and E.J. Freise, “The Role of the Allotropic Transformation in Cobalt-Base Alloys,” Cobalt, 39, June 1968.

M. Hansen, Constitution of Binary Alloys, McGraw-Hill, 1958.

J.M. Drapier, and D. Courtsouradis, “Cobalt-Chromium-Tungsten,” Metals Handbook, 8, ASM, 1973.

L. Remy, and A. Pineau, “Twinning and Strain-Induced FEE — HCP Transformation on the Mechanical Properties of Co-Ni-Cr-Mo Alloys,” Materials Science and Engineering, 26, 1976.

E. Rabinowicz, Friction and Wear of Materials, John Wiley and Sons, Inc., 1975.

K.J. Bhansali, “Adhesive Wear of Nickel and Cobalt-Base Alloys,” Wear of Materials 1979, ASME, 1979.

J.J. Schumacher, “A Stainless Steel Alternative to Cobalt-Wear Alloys,” Chemical Engineering, September, 1981.

ASTM G-65-80. Annual ASTM Standards, Part 10; ASTM, 1980.

J.S. Hansen, J.E. Kelley, and F.W. Wood, “Erosion Testing of Potential Valve Materials for Coal Gasification Systems,” U.S. Department of the Interior Report Ri8335, 1979.

Rights and permissions

About this article

Cite this article

Antony, K.C. Wear-Resistant Cobalt-Base Alloys. JOM 35, 52–60 (1983). https://doi.org/10.1007/BF03338205

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03338205