Summary

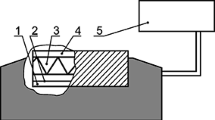

A test facility consisting of an environmental chamber, a remote extensometer, and a miniature three-zone furnace has been developed for use with a computerized model 1116 Instron. Experiments can be done in either vacuum or inert gas. The temperature of the specimen is controlled from three 125-µm-diameter, bare-wire, type K thermocouples which are spot welded to the sample. Over the 2.5-cm-gage length, the temperature is constant to within 1°K, and there is negligible control ripple. A remote extensometer, which attaches to the shoulders of the sample, allows the strain to be measured continuously using a standard, clip-on strain gage.

Examples of tensile tests, creep tests, stress-drop tests, and stress relaxation, using Zr-2.5 wt.% Nb specimens at temperatures in the vicinity of 0.5 Tm, are presented.

Similar content being viewed by others

References

A. S. Argon, “Physical Basis of Constitutive Equations for Inelastic Deformation,” in Constitutive Equations in Plasticity, edited by A. S. Argon, MIT Press, Cambridge, Massachussets, 1975, pp. 1–22.

J. L. Derep, S. Ibrahim, R. Rouby, and G. Fantozzi, “Deformation Behaviour of Zircaloy-4 Between 77 and 900 K,” Acta Metallurgica, 28 (1980), pp. 607–619.

B. D. Clay and G. B. Redding, “The Stress-Rupture Testing of Zircaloy Tube at 800°C,” CEGB Report RD/B/N3129, November 1974.

W. R. Clendening, “Primary and Secondary Creep Properties for Zircaloy Cladding at Elevated Temperatures of Interest in Accident Analysis,” paper presented at the 3rd International Conference on Structural Mechanics in Reactor Technology, London, England, September 1975.

R. H. Marion, “A Short-Time, High Temperature Mechanical Testing Facility,” Journal of Testing and Evaluation, 6 (1978), pp. 3–8.

S. R. MacEwen, “Mechanical Testing: Theme and Variations,” Industrial Research, March 1975.

S. R. MacEwen, R. G. Fleck, E T C. Ho, and O. T. Woo, “Deformation of α-Zirconium in the Vicinity of 0.5 Tm,” Metallurgical Transactions, 12A (1981), pp. 1751–1759.

H. E. Rosinger and D. O. Northwood, “The Elastic Properties of Zirconium Alloy Fuel Cladding and Pressure Tubing Materials,” Journal of Nuclear Materials, 79 (1979), pp. 170–179.

Additional information

Editor’s Note: This article appears in Novel Techniques in Metal Deformation Testing, edited by R. H. Wagoner, The Metallurgical Society of AIME, Warrendale, Pennsylvania. Copyright 1983.

Rights and permissions

About this article

Cite this article

Ho, E.T.C., MacEwen, S.R. A Facility for Precise Measurement Of Mechanical Properties At Elevated Temperatures. JOM 35, 25–29 (1983). https://doi.org/10.1007/BF03338201

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03338201