Abstract

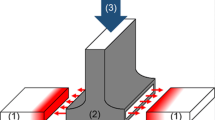

Hot plate welding is one of the most popular methods for joining plastics by utilizing heat conduction to plasticize and join thermoplastics. In comparison to competitive welding processes, hot plate welding generates high weld seam qualities but is characterized by a long cycle time; from 20 s, for small parts, to about 30 min. Cycle time itself is dominated by the cooling time. This paper reports on the influence of different cooling methods to reduce the cooling time for hot plate welding of polymers. In the initial investigations, water and nitrogen were used as cooling media (free convection) and were compared with compressed air (forced convection). The results of the initial investigations lead to more detailed analyses of forced cooling by compressed air. In the subsequent investigations, different parameters of compressed air were examined to reduce cooling time while retaining the weld seam quality. The parameters of compressed air: air flow, temperature and humidity were analysed to optimize the cooling time for amorphous and semi-crystalline polymers. It was found that the reduction of cooling time by compressed air leads to good results. Cooling time savings of 85 % could be achieved. Additionally, the weld seam quality was investigated by measuring the weld seam strength and analysing residual stresses. The weld seam strength is not influenced by the cooling method, but the cooling method influences the size of the stress field of the welded specimens.

Similar content being viewed by others

References

Grundlagen des Fügens von Kunststoffen — Basics of Joining, Hanser Fachbuchverlag, Wien, 2004, pp. 110 (in German).

Grewel D., Benatar A. and Park J.: Plastics and composites welding handbook, Carl Hanser Verlag, Munich, 2003.

Ermittlung verfahrenstechnischer Einsatzpotenziale und -grenzen des Heizelementschweiβprozesses unter Berücksichtigung der Zykluszeit und Qualitätsoptimierung — Investigation of applications, potentials and limitations of the hot plate welding process with regard to cycle time and quality optimization, Final Report AiF 13.954, DVS (2008) (in German).

Fachbuchreihe Schweiβtechnik 68/IV Titel: Fügen von Kunststoffen — Joining Plastics, Taschenbuch DVS-Merkblätter und -Richtlinien Kurzreferat, 2006 (in German).

Rietschel H.: Raumklimatechnik, Room air conditioning, Springer Verlag, 1994, pp. 252 (in German).

Ehrenstein G.W., Pongratz S.: Beständigkeit von Kunststoffen, Resistance of plastics, Hanser Fachbuchverlag, München, 2007 (in German).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Friedrich, N., Hoffschlag, R., Schöppner, V. et al. Cycletime Reduction by Forced Air Cooling for Hot Plate Welding. Weld World 56, 101–107 (2012). https://doi.org/10.1007/BF03321340

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321340