Abstract

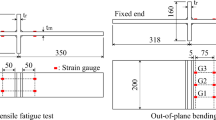

When repairing fatigue damage by welding, the fatigue strength of cracked joints needs to be restored and also improved to prevent the reoccurrence of cracks. In this study, a new welding wire called low temperature transformation (LTT) welding wire, which enables the introduction of compressive residual stresses around a weld bead and the reduction of weld deformation, was applied to the weld repair. Its applicability was investigated by fatigue tests with compact tension specimens and a plate girder specimen, The compact tension specimens revealed that compressive residual stresses introduced by LTT welding wire have positive effects on crack initiation and propagation behaviour. The plate girder specimen indicated that the fatigue lives of cracked joints are restored and also improved by weld repair with LTT welding wire. Therefore, weld repair with LTT welding wire makes it possible to improve the fatigue strength of cracked joints.

Similar content being viewed by others

References

Miki C.: Retrofitting engineering for fatigue damaged steel structures, IIW Doc. XIII-2284-09, 2009.

Wylde J.G.: The fatigue performance of repaired fillet welds, The Welding Institute Research Report, 1983, no. 215.

Yamada K., Sakai Y., Kondo A. and Kikuchi Y.: Weld repair of cracked beams and residual fatigue life, Proceedings of JSCE, 1986, no. 374/I-6, pp. 373s-382s.

Miki C., Takenouchi H., Mori T. and Ohkawa S.: Repair of fatigue damage in cross bracing connections in steel girder bridges, Proceedings of JSCE, 1989, no. 404/I-11, pp. 31s-39s.

Ohta A., Watanabe O., Matsuoka K., Siga C., Nishijima S., Maeda Y., Suzuki N. and Kubo T.: Fatigue strength improvement by using newly developed low transformation temperature welding material, Doc. IIW-1439, Welding in the World, 1999, vol. 43, no. 6, pp. 38–42.

Ohta A., Maeda Y., Nguyen N.T. and Suzuki N.: Fatigue strength improvement of box section beam by low transformation temperature welding wire, Doc. IIW-1481, Welding in the World, 2000, vol. 44, no. 5, pp. 26–30.

Miki C. and Anami K.: Fatigue strength improvement of welded joint by addition welding with low temperature metallurgical transformation electrode, IIW Doc. XIII-1827-00, 2000.

Ohta A., Suzuki N., Maeda Y. and Maddox S.J.: Fatigue strength improvement of lap welded joints by low transformation temperature welding wire — Superior improvement with strength of steel, Doc. IIW-1583, Welding in the World, 2003, vol. 47, no. 3/4, pp. 38–43.

Tominaga T., Ishikawa T. and Miki C.: Fatigue life improvement of existing bridge girders by low temperature transformation electrode, IIW Doc. XIII-1999-03, 2003.

Ohta A., Maeda Y. and Suzuki N.: Fatigue life extension by repairing fatigue cracks initiated around box welds with low transformation temperature welding wire, Doc. IIW-1507, Welding in the World, 2001, vol. 45, no. 5/6, pp. 3–8.

Miki C., Nishino F., Hirabayashi Y. and Takena K.: Influence of residual welding stress on fatigue crack growth rate, Proceedings of JSCE, 1983, no. 330, pp. 161-168.

Kitsunai Y., Kobayashi H., Narumoto A., Ishizuka T., Iida K. and Yoshihisa E.: Effect of residual stress on fatigue crack growth behavior of STS 42 steel weldments, Journal of JSMS, 1987, vol. 36, no. 409, pp. 1077–1083 (in Japanese).

ASTM E647-08: Standard test method for measurement of fatigue crack growth rates, 2008.

Kikukawa M., Jono M., Tanaka K. and Takatani M.: Measurement of fatigue crack propagation and crack closure at low stress intensity level by unloading elastic compliance method, Journal of JSMS, 1976, vol. 25, no. 276, pp. 899–903 (in Japanese).

Barsom J.M. and Rolfe S.T.: Fracture and fatigue control in structures, 3rd edition, ASTM International, 1999.

Barsom J.M. and McNicol R.C.: Effect of stress concentration on fatigue-crack initiation in HY-130 steel, ASTM STP 559, 1974, pp. 183–204.

Clark W.G. Jr.: Evaluation of the fatigue crack initiation properties of type 403 stainless steel in air and steam environments, ASTM STP 559, 1974, pp. 205–224.

Japanese Society of Steel Construction, Fatigue design recommendations for steel structures, 1993.

Kitsunai Y.: Effect of specimen size and configuration on fatigue crack growth behavior of mild steel butt welded joints, Journal of JSMS, 1983, vol. 32, no. 354, pp. 304–309 (in Japanese).

Murakami R. and Akizono K.: On the estimation of fatigue crack growth rate at welding residual stresses fields, Quarterly Journal of JWS, 1984, vol. 2, no. 4, pp. 144–150 (in Japanese).

Elber W.: Fatigue crack closure under cyclic tension, Engineering Fracture Mechanics, 1970, vol. 2, no. 1, pp. 37–45.

Yamada K., Makino T., Baba C. and Kikuchi Y.: Fatigue analysis based on crack growth from toe of gusset end weld, Proceedings of JSCE, 1980, no. 303, pp. 31-41 (in Japanese).

Mori T. and Miki C.: Aspect ratios of surface fatigue cracks originated in fillet welded joints, Journal of Structural Engineering, JSCE, 1995, vol. 41A, pp. 829–838 (in Japanese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Postdoctoral Research Assistant

Rights and permissions

About this article

Cite this article

Miki, C., Hanji, T. & Tokunaga, K. Weld Repair for Fatigue-Cracked Joints in Steel Bridges by Applying Low Temperature Transformation Welding Wire. Weld World 56, 40–50 (2012). https://doi.org/10.1007/BF03321334

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321334