Abstract

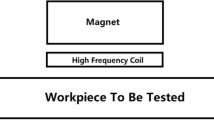

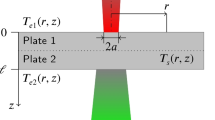

Today’s automotive engineering increasingly demands state-of-the-art quality control. In order to assure their quality, components have to be inspected — ideally by means of non-destructive tests. However, many test cases do not offer reliable and automated non-destructive testing methods. Active thermography offers solutions to assure joint quality. This relatively new non-destructive evaluation method for materials and components is robust, contactless and two-dimensional. This paper provides an overview on the physical properties of the different investigated thermographic technologies: ultrasound, inductive and optical excitation of heat flows. By demonstrating the various test cases, by testing structural and elastic adhesives, mechanical clinch joints and laser-welded joints, the possibilities of respective excitation methods were discussed and examples of the results were demonstrated. Furthermore, the aspects of quality rating and automated testing were reflected.

Similar content being viewed by others

References

Buschke P. and Schappacher W.: Trends in the automotive industry steer new NDT applications, Insight, September 2006, vol. 48, no. 9, pp. 532–536.

Maldague X.: Infrared and thermal testing-volume 3: Nondestructive Testing Handbook — Third edition; American Society for Non-destructive Testing, 2001.

Wu D.: Lockin-Thermografie für die zerstörungsfreie Werkstoffprüfung und Werkstoffcharakterisierung, Lockin-Thermography for Non-Destructive Testing and characterization of materials, PHD Thesis at the IKT of Stuttgart University, 1996 (in German).

Adams R.D. and Drinkwater B.W.: Non-destructive testing of adhesively-bonded joint, International Journal of Materials and Product Technology, 1999, vol. 14, no. 5/6, pp. 385–398.

Habenicht G.: Kleben: Grundlagen, Technologie, Anwendungen, 3. erw. Auflage, Adhesive bonding: Fundamentals, technology, applications, Third enlarged edition, Springer Verlag, Berlin, 1997 (in German).

Hasenberg D., Dilger K. and Böhm S.: Non-destructive characterization of adhesive joint using lock-in thermography, WCNDT, World Conference on Non-Destructive Testing, 2004, 16, pp. 1–5.

Hahn O. and Klemens U.: Fügen durch Umformen: Nieten und Durchsetzfügen, Innovative Verbindungsverfahren für die Praxis, Joining by deformation: Innovative joining processes for practice, Stahl-Dokumentation, Studiengesellschaft Stahlanwendung, Düsseldorf, 1996, Band 707 (in German).

Zweschper T.: Zerstörungsfreie und berührungslose Charakterisierung von Fügeverbindungen mittels Lockin Thermografie — Nondestructive and non contact characterization of joints by lock-in thermogaphie, ZfP-Zeitung, 2000, vol. 71, pp. 43–46 (in German).

Richter A.: Möglichkeiten und Grenzen der Prozeßüberwachung zur Qualitätssicherung beim Fügen durch Umformen, Capabilities and limits of process monitoring for quality assurance of joining by forming, PHD Thesis at the Hamburg-Harburg University, 1997 (in German).

Neugebauer R., Kühn T., Leopold, U., Böhm S., Dilger K. and Srajbr, C.: EinsatzderThermografiezurzerstörungsfreien Prüfung von Clinchverbindungen, Application of active thermography for Non-Destructive Testing of clinch joints, Final report of AIF- project Nr. 14890BG; 2006–2008 (in German).

Kropf A.: Application of thermography for the inspection of laser welds as employed in Touran production at Auto5000 GmbH, Automotive Circle International Conference “Joining in Automotive Engineering”, Bad Nauheim, April 25 and 26 2007, pp. 279–291.

Böhm S., Dilger K. and Tanasie G.: Qualifizierung zerstörungsfreier Prüfverfahren hinsichtlich ihrer Eignung zur Charakterisierung laserstrahlgeschweißter Überlappverbindungen an Stahl, Schweißen und Schneiden, Qualification of Non-Destructive Test methods concerning their suitability for characterizing laser beam welded lapped joints at steel, 2008, vol. 60, no. 6, pp. 310, 312-316, 318-319 (in German).

Zäh M. F., Thiemann C. and Srajbr C.: Zerstörungsfreie Prüfung von Klebverbindungen. Automatisierung der thermografischen Analyse für den Einsatz in der Serienfertigung, Non-Destructive Testing of bonded joints, Automation of thermographic inspection for application in series manufacturing, wt Werkstatttechnik online, 2008, vol. 98, no. 9, pp. 717–722 (in German).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srajbr, C., Tanasie, G., Dilger, K. et al. Active Thermography for Quality Assurance of joints in automobile manufacturing. Weld World 55, 90–97 (2011). https://doi.org/10.1007/BF03321312

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321312