Abstract

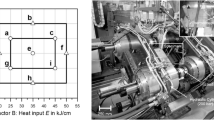

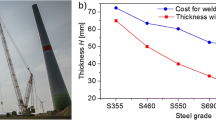

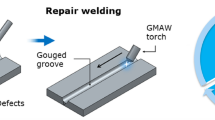

Realization and safe operation of modern welded structures are progressively requiring for base and filler materials to cope with continually increasing loads, Analyses with a view to crack prevention therefore need to accommodate particularly the structural design (restraint intensity) and the thermomechanical effects in terms of stresses introduced during welding, Against this background, multi-run welding experiments were carried out in an IRC - (Instrumented Restraint Cracking) Test under defined restraint intensity in order to examine the influence of heat control (preheating and interpass temperatures) on the weldinq-specific forces and stresses, The experiments revealed significant rises in the reaction force and stress after welding with increasing preheating and interpass temperature, Furthermore, various concepts for calculating the preheating temperature are discussed, It is demonstrated that the hitherto existing concepts for high-strength finegrained structural steels can lead to divergent results.

Similar content being viewed by others

References

Miki C., Homma K. and Tominaga T.: High strength and high performance steels and their use in bridge structures, Journal of Constructional Steel Research, 2002, vol. 58, pp. 3–20.

Boellinghaus Th. and Hoffmeister H.: Finite element calculations of pre- and post-heating procedures for sufficient hydrogen removal in butt joints, Mathematical Modelling of Weld Phenomena 3, Maney Publishing, ISBN: 186125010 X, 1997, pp. 726-756.

DIN EN 1011-2:2001, Welding — Recommendation for welding of metallic materials — Part 2: Arc welding of ferritic steels, 2001.

Wongpanya P., Boellinghaus Th. and Lothongkum G.: Numerical simulation of hydrogen removal heat treatment in high strength structural steel welds, Mathematical Modelling of Weld Phenomena 8, ISBN 978-3-902465-69-6, 2007, pp. 643–665.

Satoh K., Ueda Y. and Kihara H.: Recent trends of research into restraint stresses and strains in relation to weld cracking, Doc. IIW-425, Welding in the World, 1973, vol. 11, no. 5/6, pp. 133–156.

Boellinghaus Th., Kannengiesser Th. and Neuhaus M.: Effects of the structural restraint intensity on the stress strain build up in butt joints, Mathematical Modelling of Weld Phenomena 7, TU Graz, ISBN 3-901351-99-X, 2005, pp. 651–669.

Wongpanya P., Boellinghaus Th. and Lothongkum G.: Effects of hydrogen removal heat treatment on residual stresses in high strength structural steel welds, Welding in the World, 2006, vol. 50, Special Issue, pp. 96–103.

Yurioka N., Suzuki H., Ohshita S. and Saito S.: Determination of necessary preheating temperature in steel welding, Welding Journal, 1983, no. 6, pp. 147s-153s.

Florian W.: Cold cracking in high strength weld metal — Possibilities to calculate the necessary preheating temperature, IIW Doc. IX-2006-01, 2001.

Wongpanya P., Boellinghaus Th., Lothongkum G. and Kannengiesser Th.: Effects of preheating and interpass temperature on stresses in S 1100 QL multi-pass buttwelds, Doc. IIW-1851, Welding in the World, 2008, vol. 52, no. 3/4, pp.79–92.

Håkansson K.: Weld metal properties for extra high strength steels, Doctoral Thesis, ISSN 1650-1888, TRITA-IIP-02-10, The Royal Institute of Technology, 2002.

Böllinghaus Th. and Kannengiesser Th.: Cold cracking test procedures — IIW Doc. II-1587-07/IX-2241-07, 2007.

Hoffmeister H.: Concept and procedure of the IRC Test for assessing hydrogen assisted cracking, Steel Research, July 1986, vol. 57, no. 7, pp. 344–347.

Hoffmeister H., Harneshaug I.S. and Roaas S.: Investigation of the conditions for weld metal hydrogen cracking of low carbon offshore steels by the IRC weldability test, Steel research, 1987, vol. 58, no. 3, pp. 134–141.

Nevasmaa P.: Prevention of weld metal hydrogen cracking in high-strength multipass welding, Doc. IIW-1617, Welding in the World, 2004, vol. 48, no. 5/6, pp. 2–18.

Graville B.A.: A survey review of weld metal hydrogen cracking, Doc. IIW-851, Welding in the World, 1986, vol. 24, no. 9/10, pp. 190–198.

Graville B.A.: Interpretive report on weldability tests for hydrogen cracking of higher strength steels and their potential for standardization, Welding Research Council Bulletin, vol. 400, ISSN 0043-2326, 1995.

Seo J.S., Kim H.J., Ryoo H.S.: Microstructural parameter controlling weld metal cold cracking, Journal of Achievements in Materials and Manufacturing Engineering, 2008, vol. 27, no. 2, pp. 199–202.

Cwiek J.: Hydrogen degradation of high strength weldable steels, Journal of Achievements in Materials and Manufacturing Engineering, 2007, vol. 20, no. 1–2, pp. 223–226.

Cwiek J.: Hydrogen enhanced-cracking of high-strength steel welded joints, Advances in Materials Sciences, DOI: 10.2478/v10077-008-0045y, 2008, vol. 8, no. 4, pp. 4–13.

Matsuda F., Nakagawa H., Shinozaki K., Morimoto H. and Sanamkatsu Y.: Criterion of alternative initiation of cold cracking in HAZ or weld metal for root pass welds of high strength steels, Transactions of JWRI, 1983, vol. 12, no. 2, pp. 75–85.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kannengiesser, T., Lausch, T. & Kromm, A. Effects of Heat Control on the Stress Build- up during High- Strength Steel Welding under defined restraint conditions. Weld World 55, 58–65 (2011). https://doi.org/10.1007/BF03321308

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321308