Abstract

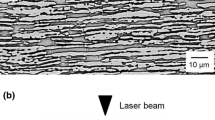

1.4462 (UNS S31803) duplex stainless steel (DSS) and EN 1.4410 (UNS S32750) superduplex stainless steel (SDSS) have been welded by fibre laser welding and plasma arc welding (PAW) processes with-Cout filler metal. Impact toughness testing at various temperatures from 20 °C down to −60 °C was carried out. Microstructural examination included macro and microphotographs of the cross-sections, ferrite content measurements and hardness survey of the weld zones. Weld metal impact toughness results on the order of 100 J were obtained while values between 30 J and 60 J were measured respectively for plasma arc and laser welds of the duplex and superduplex grades even at −60 °C test temperature. Ferrite content of the welds varied generally in an acceptable range which affected the microstructure and the toughness properties. Better toughness results of plasma arc welds of both duplex and superduplex material compared to the laser welds are attributed to the balanced microstructure of the weld metal having ferrite- austenite ratio close to 50:50 % obtained by controlled heat input.

Similar content being viewed by others

References

Lippold J.C. and Kotecki D.J.: Welding metallurgy and weldability of stainless steels, John Wiley & Sons, New Jersey, 2005, pp. 230–253.

Davis J.R.: ASM Speciality Handbooks: Stainless Steels, American Society for Metals Materials Park, ASM, Ohio, 1994.

Van Nassau L., Meelker H. and Hilkes J.: Welding duplex and superduplex stainless steels, Doc. IIW-1165, Welding in the World, 1993, vol. 31, no. 5, pp. 322–343.

Karlsson L., Rigdal S., Bergquist E.L. and Arcini, H.: Effects of alloying elements on properties of duplex weld metals. Int. Conf. Duplex 2007, Italy, October 2007, paper 11.

Folkhard E.: Welding metallurgy of stainless steels, Springer-Verlag: Vienna, New York, 1984, p. 186.

Kaluc E. and Taban E.: Paslanmaz Celikler, Gelistirilen Yeni Turleri ve Kaynak Edilebilirlikleri, Stainless steels, their modified types and weldability, TMMOB MMO 2007/461, A publication of Mechanical Engineering Chamber of Turkey, ISBN: 978-9944-89-438-8, 2007 (in Turkish).

Nelson D.E., Baeslack W.A. and Lippold J.C.: Characterization of the weld structure in a duplex stainless steel using color metallography, Materials Characterization, 1997, vol. 39, no. 2–5, pp. 467–477.

NN, Practical guidelines for the fabrication of duplex stainless steels, I ternational Molybdenum Association, UK, 2009.

Charles J.: Composition and properties of duplex stainless steels, Welding of Welding steels, Welding in the World, June 1995, vol.36, pp. 43–54.

Tavares S.S.M., Pardal J.M., Lima L.D., Bastos I.N., Nascimento A.M. and de Souza J.A.: Characterization of microstructure, chemical composition, corrosion resistance and toughness of a multipass weld joint of superduplex stainless steel UNS S32750, Materials Characterization, 2007, vol. 58, no. 7, pp. 610–616.

Karlsson L.: Intermetallic phase precipitation in duplex stainless steels and weld metals: Metallurgy, Influence on Properties, Welding and Testing Aspects, WRC Bulletin 438, 1999, ISSN 0043-2326, pp. 1-23.

Varol I., Baeslack W.A. and Lippold J.C.: Characterization of weld solidification cracking in a duplex stainless steel, Materials Characterization, 1997, vol. 39, no. 2–5, pp. 555–573.

Sun Z., Kuo M., Annergen I. and Pan D.: Effect of dual torch technique on duplex stainless steel welds, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2003, vol. 356, no. 1–2, pp. 274–282.

Taban E.: Toughness and microstructural analysis of superduplex stainless steel joined by plasma arc welding, Journal of Materials Science, 2008, vol. 43, no. 12, pp. 4309–4315.

Muthupandi V., Srinivasan P.B., Seshadri S.K. and Sunderasan S.: Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2003, vol. 358, no. 1–2, pp. 9–16.

Srinivasan P.B., Muthupandi V., Dietzel, W. and Sivan, V.: An assessment of impact strength and corrosion behaviour of shielded metal arc welded dissimilar weldments between UNS 31803 and IS 2062 steels, Materials and Design, 2006, vol. 27, no. 3, pp. 182–191.

Srinivasan P.B., Muthupandi V., Dietzel W. and Sivan, V., Microstructure and corrosion behavior of shielded metal arc-welded dissimilar joints comprising duplex stainless steel and low alloy steel, Journal of Materials Engineering and Performance, 2006, vol. 15, no. 6, pp. 758–764.

Kordatos J.D., Fourlaris G. and Papadimitrou G.: The effect of cooling rate on the mechanical and corrosion properties of SAF 2205 (UNS 31803) duplex stainless steel, Scripta Materialia, 2001, vol. 44, no. 3, pp. 401–408.

Petronius I. and Bamberger M.: Microstructure and properties following welding of duplex stainless steel using coated electrodes, Science and Technology of Welding and Joining, 2001, vol. 6, no. 2, pp. 79–83.

McPherson N.A., Li Y and Baker T.N.: Microstructure and properties of as welded duplex stainless steel, Science and Technology of Welding and Joining, 2000, vol. 5, no. 4, pp. 235–244.

Karlsson L. and Tolling J.: Experiences and new possibilities in welding duplex stainless steels. Proc., IIW Regional Congress on Welding and Related Inspection Technologies, South Africa, 2006.

Sieurin, H. and Sandström R.: Austenite reformation in the heat-affected zone of duplex stainless steel 2205, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2006, vol. 418, no. 1–2, pp. 250–256.

Kuroda T., Ikeuchi K. and Ikeda H.: Flash butt resistance welding for duplex stainless steels, Vacuum, 2006, vol. 80, no. 11–12, pp. 1331–1335.

Saeid T., Abdollah-Zadeh A., Assadi H. and Malek Ghaini F.: Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2008, vol. 496, no. 1–2, pp. 262–268.

Comer A. and Looney L.: Crack propagation resistance of Zeron 100 weld metal fabricated using the GTA and SMA welding processes, Theoretical and Applied Fracture Mechanics, 2006, vol. 45, no. 2, pp. 139–147.

Sato Y.S., Nelson T.W., Sterling C.J., Steel R.J. and Petterson C.O.: Microstructure and mechanical properties of friction stir welded SAF 2507 superduplex stainless steel, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2005, vol. 397, no. 1–2, pp. 376–384.

Migiakis K. and Papadimitriou G.D.: Effect of nitrogen and nickel on the microstructure and mechanical properties of plasma welded UNS S32760 super-duplex stainless steels, Journal of Materials Science, 2009, vol. 44, no. 23, pp. 6372–6383.

Cervo R., Ferro R and Tiziani, A.:Annealing temperature effects on super duplex stainless steel UNS S32750 welded joints I: microstructure and partitioning of elements, Journal of Materials Science, 2010, vol. 45, no. 16, pp. 4369–4377.

Urena A., Utero E., Utrilla M.V. and Munez C.J.: Weldability of a 2205 duplex stainless steel using plasma arc welding, Journal of Materials Processing Technology, 2007, vol. 182, no. 1–3, pp. 624–631.

Taban E.: Joining of duplex stainless steel by plasma arc, TIG, and plasma Arc+TIG welding processes, Materials and Manufacturing Processes, 2008, vol. 23, no. 8, pp. 871–878.

Capello E, R Chiarello P., Previtali B. and Vedani M.: Laser welding and surface treatment of a 22Cr/5Ni/3Mo duplex stainless steel, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 2003, vol. 351, no. 1–2, pp. 334–343.

Ku J. S., Ho J. and Tjong S.C.: Properties of electron beam welded SAF 2205 duplex stainless steel, Journal of Materials Processing Technology, 1997, vol. 63, no. 1–3, pp. 770–775.

Yip W.M., Man H.C. and Ip W.H.: Optimisation of Nd-YAG laser welding of superduplex stainless steel by parameter design, Science and Technology of Welding and Joining, 1999, vol. 4, no. 4, pp. 226–232.

Westin E. M., Stelling K. and Gumenyuk A.: Singlepass laser-GMA hybrid welding of 13.5 mm thick duplex stainless steel, Doc. IIW-2028, Welding in the World, 2011, vol. 55, no. 1/2, pp. 39–49.

Quintino L., Costa A., Miranda R., Yapp D., Kumar V. and Kong C.J.: Welding with high power fiber lasers — A preliminary study, Materials and Design, 2007, vol. 28, no. 4, pp. 1231–1237.

NN, Uranus 45N Mo, Product Catalogue, Industeel, 2007, pp. 8.

Nicholas J.: What is the difference between heat input and arc energy, TWI FAQ, www.twi.co.uk, 2003.

Gooch T.G.: Welding new stainless steels for the oil and gas industry, Corrosion NACE Expo 2000, March 2000, Orlando, USA.

Muthupandi V., Bala Srinivasan P., Seshadri S.K. and Sundaresan S.: Corrosion behaviour of duplex stainless steel weld metals with nitrogen additions, Corrosion Engineering Science and Technology, 2003, vol. 38, no. 4, pp. 303–308.

Zambon A. and Bonollo F.: Rapid solidification in laser welding of stainless steels, Materials Science & Engineering: A, Structural Materials: Properties, Microstructure and Processing, 1994, vol. 178, no. 1–2, pp. 203–207.

Ramirez A.J., Brandi S.D. and Lippold J.C.: Secondary austenite and chromium nitride precipitation in simulated heat-affected zones of duplex stainless steels, Science and Technology of Welding and Joining, 2004, vol. 9, no. 4, pp. 301–313.

Zhang J.X., Li Q.Y., Li W.W. and Zhang T.H.: The microstructure and impact toughness of simulated welding HAZ in 2205 duplex stainless steel, Rare Metal Materials and Engineering, 2006, vol. 35, no. 11, pp. 1822–1825.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taban, E., Kaluc, E. Welding behaviour of Duplex and Superduplex Stainless Steels using Laser and Plasma ARC Welding processes. Weld World 55, 48–57 (2011). https://doi.org/10.1007/BF03321307

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321307