Abstract

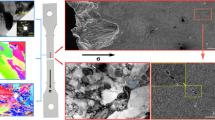

Martensitic 9–12 wt. % Cr steels have been favoured grades for high temperature components in thermal power generation industry. The excellent creep properties of these steel grades can be related to their optimized martensitic microstructure containing finely dispersed precipitates. In the present work, the influence of weld thermal cycle and subsequent post-weld heat treatment on precipitate evolution of a martensitic 9 wt. % Cr steel is investigated. The microstructure at different stages of the thermal cycle is characterized by optical microscopy, scanning electron microscopy and transmission electron microscopy. The precipitates are identified by analytical transmission microscopy, namely energy-filtered TEM, energy dispersive X-ray diffraction and electron energy loss spectroscopy. The experimental findings are compared to kinetic simulations of the precipitate evolution during the complete thermal cycle using the software MatCalc. Results of kinetic simulations are in good agreement with experimental data. Optimization of heat treatment procedure as well as further application of microstructure modelling is discussed.

Similar content being viewed by others

References

Scarlin B., Kern T.U. and Staubli M.: The European efforts in material development for 650 °C USC power plants — COST 522, Proceedings of the International Conference on: 4th International Conference on Advances in Materials Technology for Fossil Power Plants, EPRI, 2004.

Fujita T.: Materials for future power plants, Advanced Materials and Processes, June 2000, pp. 55-58.

Blum R., Vanstone R.W. and Messelier-Gouze C.: Materials development for boilers and steam turbines operating at 700 °C, 4th International Conference on Advances in Materials Technology for Fossil Power Plants, Hilton Head Island, ASM International, 2005.

Bhadeshia H.K.D.H.: Design of ferritic creep-resistant steels, ISIJ International, 2001, vol. 41 no. 6, pp. 626–640.

Sawada K., Taneike M., Kimura K. and Abe F.: In situ observation of lath structure in 9% chromium creep resistant steel, Materials Science and Technology, 2003, vol. 19, no. 6, pp.739–742.

Taneike M., Sawada K. and Abe F.: Effect of carbon concentration on precipitation behavior of M23C6 carbides and MX carbonitrides in martensitic 9Cr steel during heat treatment, Metallurgical and Materials Transactions A, 2004, vol. 35A, no. 4, pp. 1255–1262.

Janovec J., Svoboda M. and Blach J.: Evolution of secondary phases during quenching and tempering 12% Cr steel, Materials Science and Engineering A, 1998, vol.A249,no. 1-2, pp. 184–189.

Hald J. and Korcakova L.: Precipitate stability in creep resistant ferritic steels — experimental investigations and modelling, ISIJ International, 2003, vol. 43, no. 3, pp. 420–427.

Cerjak H. and Mayr P.: Creep strength of welded joints of ferritic steels, Creep resistant steels, Woodhead Publishing, 2008, pp. 472-503.

Francis J.A., Mazur W. and Bhadeshia H.K.D.H.: Type IV cracking in ferritic power plant steels Materials Science and Technology, 2006, vol. 22, no. 12, pp. 1387–95.

Laha K., Chandravathi K.S., Parameswaran P., Bhanu Sankara, Rao K. and Mannan S.L.: Characterization of microstructures across the heat-affected zone of the modified 9Cr-1Mo weld joint to understand its role in promoting Type IV cracking, Metallurgical and Materials Transactions A, 2007, vol. 38A, no. 1, pp. 58–68.

Mayr P.: Evolution of microstructure and mechanical properties of the heat affected zone in B-containing 9% chromium steels, Graz, Graz University of Technology, 2007.

Sonderegger B.: Modifications of stereological correction methods for precipitate parameters using transmission microscopy, Ultramicroscopy, 2006, vol. 106, no. 10, pp. 941–950.

Kozeschnik E. and Buchmayr B.: Mathematical Modelling of Weld Phenomena 5, London, Institute of Materials, 2001, pp. 349–361.

Svoboda J., Fischer F.D., Fratzl P. and Kozeschnik E.: Modelling of kinetics in multi-component multi-phase systems with spherical precipitates I. — Theory, Materials Science and Engineering A, 2004, vol. 385, no. 1-2, pp. 166–174.

Kozeschnik E., Svoboda J., Fratzl P. and Fischer F.D.: Modelling of kinetics in multi-component multi-phase systems with spherical precipitates II. — Numerical solution and application, Materials Science and Engineering A, 2004, vol. 385, no. 1-2, pp. 157–165.

Kozeschnik E., Svoboda J. and Fischer F.D.: Modified evolution equations for the precipitation kinetics of complex phases in multi-component systems, CALPHAD, 2005, vol. 28, no. 4, pp. 379–382.

Sonderegger B.: Characterisation of the substructure of modern power plant steels using the EBSD-Method, Graz, Graz University of Technology, 2005 (in German).

Andersson J.O., Höglund L., Jönsson B. and Ågren J.: Computer simulations of multicomponent diffusional transformations in steel, Fundamentals and Applications of Ternary Diffusion, G.R. Purdy (ed.), New York, Pergamon Press, 1990, pp. 153–163.

Kozeschnik E. and Holzer I.: Precipitation during heat treatment and service: Characterization, simulation and strength contribution, Creep-resistant steels, F. Abe, T.-U. Kern, R. Viswanathan (Eds.), Cambridge, Woodhead Publishing Ltd., 2008, pp. 305–328.

Author information

Authors and Affiliations

Corresponding author

Additional information

formerly with Institute for Materials Science and Welding, Graz University of Technology

formerly with Institute for Materials Science and Welding, Graz University of Technology

Rights and permissions

About this article

Cite this article

Mayr, P., Holzer, I. & Cerjak, H. Evolution Of Precipitate Structure in the heat-affected zone of a 9 wt. % Cr Martensitic Steel during welding and post-weld heat treatment. Weld World 55, 70–77 (2011). https://doi.org/10.1007/BF03321296

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321296