Abstract

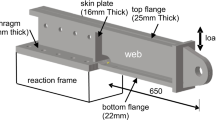

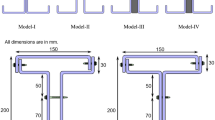

This paper concerns the applicability of partial joint preparation (PJP) groove welds to beam-to-column connections. Two full-sized beam-to-column connections, with rectangular hollow section columns and PJP groove welds at the ends of the beam flanges, were tested under cyclic loads. All the specimens were made with one-sided connections. When the unfused regions created by PJP groove welds were reinforced by fillet welds so that the welded joints have a sufficient cross-sectional area, the connections showed sufficient deformation capacity, although ductile cracks initiated at the weld toes and grew stably. Test results were well reproduced by non-linear FE analyses. Strains sustained at points around internal discontinuities were found to be low because of greater cross-sectional areas of welded joints compared with the cross-sectional area of the beam flanges. Fracture toughness properties of numerically modelled connections were evaluated by using a failure assessment diagram approach, which was modified by considering the effect of enhanced apparent toughness of material due to the loss of crack tip constraint. Both the test results and the fracture mechanics-based assessment demonstrated that it is unlikely to initiate brittle fracture at these discontinuities when materials used in the connections have sufficient fracture toughness.

Similar content being viewed by others

References

AIJ Kinki, Full-scale test on plastic rotation capacity of steel wide-flange beams connected with square tube steel columns, Committee on Steel Building Structures, Kinki Branch of Architectural Institute of Japan, Osaka, Japan, 1997 (in Japanese).

AIJ, Technical recommendations for steel construction for buildings, Part 1 guide to steel-rib fabrications, Architectural Institute of Japan, Tokyo, Japan, 1996 (in Japanese).

Azuma K., Kurobane Y., Makino Y.: Cyclic testing of beam-to-column connections with weld defects and assessment of safety of numerically modeled connections from brittle fracture, Engineering Structures, 2000, Vol. 22, No. 12, Elsevier Science Ltd., pp. 1596–1608.

Azuma K., Kurobane Y., Makino Y.: Full-scale testing of beam-to-column connections with partial joint penetration groove welded joints, Proceedings of the 10th International Symposium on Tubular Structures, 2003, pp. 419–427.

BS 7910: Guidance on methods for assessing the acceptability of flaws in metallic structures, 1997.

ABAQUS 2004, ABAQUS v6.4 Manuals (User’s Manuals I, II and III), Hibbitt, Karlsson and Sorensen, Inc.

Iwashita T., Kurobane Y., Azuma K., Makino Y.: Prediction of brittle fracture initiating at ends of CJP groove welded joints with defects: study into applicability of failure assessment diagram approach, Engineering Structures, 2003, Vol. 25, Issue 14, Elsevier Science Ltd., pp. 1815–1826.

Anderson T.L., Dodds R.H., Jr.: Specimen size requirements for fracture toughness testing in the ductile-brittle transition region, Journal of Testing and Evaluation, 1991, Vol. 19(2), pp. 123–134.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Azuma, K., Kurobane, Y., Iwashita, T. et al. Full-Scale Testing of Beam-to-RHS Column Connections with Partial Joint Penetration Groove Welded Joints and Assessment of Safety from Brittle Fracture. Weld World 50, 59–67 (2006). https://doi.org/10.1007/BF03266525

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266525