Abstract

Improvement methods can be divided into two main groups: weld geometry modification and residual stress modification. The former remove weld toe defects and/or reduce the stress concentration while the latter introduce compressive stress fields in the area where fatigue cracks are likely to initiate. Ultrasonic impact treatment belongs to residual stress improvement methods. It makes use of an ultrasonic carrier frequency to accelerate hardened tools that, in turn, impact the weld toe. The fatigue strength of non-load carrying attachments in the as-welded condition has been experimentally compared to the fatigue strength of ultrasonic impact treated welds. Longitudinal attachment specimens made of two thicknesses of steel S355 J0 have been tested for determining the efficiency of ultrasonic impact treatment. Treated welds were found to have about 50% greater fatigue strength, when the slope of the S-N-curve is three. High mean stress fatigue testing based on the Ohta-method did not decrease the degree of weld improvement due to UIT. This indicated that the method could be also applied for large fabricated structures operating under high reactive residual stresses equilibrated within the volume of the structure.

Similar content being viewed by others

References

Maddox S.: Fatigue strength of welded structures, Abington Publishing, Cambridge, 1991.

Fisher J.W., Statnikov E.S., Tehini L.: Fatigue improvement of bridge girders by ultrasonic impact treatment (UIT), Proceedings of the IIW fatigue seminar, 2nd April 2002, Tokyo Institute of Technology, Japan.

Haagenseen P.J., Dragen A., Slind T., Orjesater O.: Prediction of the improvement in fatigue life of welded joints due to grinding, TIG-dressing, weld shape control and shot peening, Steel in Marine Structures SIMS 87, Proceedings of the 3rd international ECSC offshore conference on steel in marine structures, Edited by C. Noordhoek and J. deBack.

Haagenseen P.J.: Improving the fatigue strength of welded joints, Fatigue handbook, Editor A. Almar-Naess, Trondheim 1985.

Statnikov E.S. and others: Ultrasonic Head for Strain Hardening. Author’s Certificate No. 472782. Application date 04.07.72, “Bulletin of Inventions” No. 21, 1975.

Statnikov E.S., Stepanov V.G., Klestov M.I., Shevtsov E.M.: Residual Stresses in Welded Joints of Yu3 (Ю3) Steel Hardened by Ultrasonic Impact Tool. “Shipbuilding Technology”, 1974, No. 7, pp. 32–34.

Statnikov E.S., Stepanov V.G., Klestov M.I., Shevtsov E.M.: Corrosion-fatigue strength of Yu3 (Ю3) Steel Hardened by Ultrasonic Tool. “Shipbuilding Technology”, 1975, No. 1, pp. 70–74.

Statnikov E.S.: Applications of operational ultrasonic impact treatment (UIT) technologies in production of welded joints, doc. IIW-1384-97 (ex-doc. XIII-1667–97), Welding in the World, May–June 2000, vol. 44, No. 3, pp. 11–21.

Statnikov E.S., Muktepavel V.O., Trufyakov V.I., Kuzmenko A.Z.: Comparison of efficiency and processibility of post-weld deformation methods for increase in fatigue strength of welded joints, Northern Scientific & Technological Fund, IIW doc. XIII-1668–97.

Trufyakov V.I., Statnikov E.S., Mikheev P.P., Kuzmenko A.Z.: The efficiency of ultrasonic impact treatment (UIT) for improving the fatigue strength of welded joints; IIW doc. XIII-1745–98.

Haagenseen P.J., Statnikov E.S., Lopez-Martinez L.: Introductory fatigue tests on welded joints in high strength steel and aluminium treated by various improvement methods including ultrasonic impact treatment (UIT), IIW doc. XIII-1748–98.

Kirkhope K.J., Bell R., Caron L., Basu R.I.: K-T. Ma, Weld detail fatigue life improvement techniques, Part 1: review, Marine structures, vol. 12 (1999) pp. 447–474.

Ohta A., Matsuoka K., Suzuki N., Maeda Y.: Fatigue strength of non-load-carrying cruciform welded joints by a test maintaining maximum stress at yield strength, Engineering Fracture Mechanics, 1994, vol. 9, pp. 639–645.

Huther M.: IIW Guidance for statistics — Fatigue test results analysis, IIW doc. XIII-WG1-101–02.

Haagenseen P.J., Maddox S.J.: IIW Recommendations on post weld improvement of steel and aluminium structures, IIW doc. XIII-1815–00, rev. 4, July 2001.

Hobbacher A.: Recommendations for fatigue design of welded joints and components, IIW doc. XIII-1539-96/XV-845–96, May 2000.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lihavainen, V.M., Marquis, G. & Statnikov, E.S. Fatigue Strength of a Longitudinal Attachment Improved by Ultrasonic Impact Treatment. Weld World 48, 67–73 (2004). https://doi.org/10.1007/BF03266434

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266434

IIW-Thesaurus keywords

- Fatigue strength

- Mechanical properties

- Fatigue loading

- Loading

- Ultrasonic processing

- Post weld operations

- Peening

- Work hardening

- Combined processes

- Fatigue cracks

- Cracking

- Defects

- Corrosion

- Compression

- Stress distribution

- Residual stresses

- Welded joints

- Weld toes

- Weld metal

- Weld shape

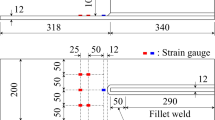

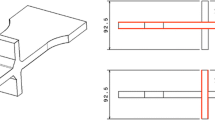

- Test pieces

- Thickness

- Nonload carrying

- GMA welding

- Arc welding

- Gas shielding arc welding

- Process parameters

- Statistical methods

- Accessories

- Carbon manganese steels

- Steels

- Practical investigations

- Classifying

- Reference lists