Abstract

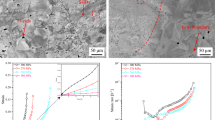

New creep-resisting weld metals of P91 grade were manufactured by manual metal arc (MMA) process producing multi-bead multi-layer test coupons, from which specimens were taken for accelerated creep testing on Gleeble physical simulator. The recently developed accelerated creep testing (ACT) procedure on Gleeble allows transforming in a relatively short time (less than 100 h) the microstructure of creep-resisting materials to the near to thermodynamic equilibrium state, resembling that of multi-year application at creep condition. Such advanced transformation of microstructure in the investigated weld metals after ACT was confirmed by microscopic and microanalytical study. The results also appeared in agreement with Thermocalc calculations. By an optimum combination of chemical compositions of the electrodes with welding procedure and post-weld heat treatment, advantageous mechanical properties were achieved as well as results of ACT indicating potentially long creep life in service exposure conditions. In discussion of the ACT results, comparisons with results of conventional creep testing have been made. The ACT procedure appears useful in fast screening of newly developed creep-resisting materials.

Similar content being viewed by others

References

Pepe J.J., Gonyea D.C.: Constant displacement rate testing at elevated temperatures, in: Fossil Power Plant Rehabilitation, ASM International, Proceedings of the International Conference, Cincinnati OH, Feb. 1989, pp. 39–45.

Mandziej S.T., Výrostková A.: Accelerated Creep Testing (ACT) Procedure for Weld Metals Using Gleeble Systems, Gleeble Application Note, DSI, Poestenkill NY, USA, 2001.

Mandziej S.T.: Low-energy dislocations and ductility of ferritic steels, Materials Science & Engineering A, 1993, vol. 164, no. 1–2, pp. 275–280.

Kidin I.N.: Fizicheskie Osnovy Elektrotermicheskei Obrabotki Metallov i Splavov, Physical Principles of Electro-thermal Treatment of Metals and Alloys, Izd. Metallurgia, Moscow, 1969 (in Russian).

Mandziej S.T., Výrostková A.: Evolution of Cr-Mo-V weld metal microstructure during creep testing — Part 1: P91 material, Doc. IIW-1822-07 (ex-doc. II-1601–06), Welding in the World, 2008, vol. 52, no. 1/2, pp. 3–26.

Mandziej ST., Marciniak J.: TEM investigations on in-situ transformation of M23C6 carbides, Proceedings of the XIth International Congress on Electron Microscopy, Kyoto, 1986, pp. 1271–72.

Woodhead J.H., Quarrell A.G.: Role of carbides in low-alloy creep-resisting steels, Journal of Iron and Steel Institute, June 1965, pp. 605–620.

Danielsen H.K., Hald J.: Behaviour of Z-phase in 9–12%Cr steels, Energy Materials, 2006, vol. 1, no. 1, pp. 49–57.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mandziej, S.T., Vyrostkova, A. & Solar, M. Accelerated Creep Testing of New Creep-Resisting Weld Metals. Weld World 54, R160–R172 (2010). https://doi.org/10.1007/BF03263502

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263502