Abstract

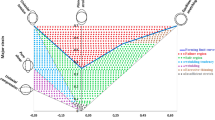

In many industries, bi-material components in the form of clad plates are used due to their superior environmental and mechanical properties. During the service life of these bi-material components, cracks or crack-like detects may develop in the cladding or at the interface (underclad discontinuities) having different orientations with respect to the interface, and may penetrate into the substrate. Welding of those damaged parts after completely removing the imperfection by gouging or grinding is a well-established industrial practice. Defect assessment of the integrity of such a repaired and complex structure should be conducted and obviously it would be a difficult task. This study aims to apply the recently developed European Structural Integrity Assessment Procedure (SINTAP), to a through thickness centre cracked clad steel wide plate, containing shallow and deep repair welds, to validate the SINTAP procedure for this type of bi-material structure and also to establish a procedure for the assessment of such a complex repaired structure. Based on the used input data, various assessment levels (including mis-match option) using the crack driving force (CDF) route are worked for predicting the failure loads. The degree of conservatism has been reduced by using higher analysis levels of the SINTAP. The SINTAP procedure has been verified and a methodology to conduct SINTAP-based assessments is presented.

Similar content being viewed by others

References

R6, “Assessment of the integrity of structures containing defects”, British Energy Generation Ltd, 1999.

British Standard BS7910, “Guide on methods for assessing the acceptability of flaws in fusion welded structures”, 1999.

Japan Welding Engineering Society, Technical report: WES TR 2805 and 2508, “Method for the assessment of the brittle fracture in steel weldments subjected to cyclic and dynamic large loading”, 2000.

SINTAP: Structural integrity assessment procedure for European industry. Final procedure, Brite Euram Project No. BE95–1426, British Steel, 1999.

S. Webster and A. Bannister, “Structural integrity assessment procedure for Europe-of the SINTAP programme overview”, Eng. Fract. Mechanics, 67 (2000), 481–514.

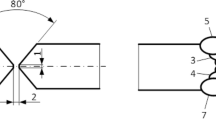

A. K. Motarjemi, M. Kocak and V. Ventzke, “Fracture characterisation of a bi-layer steel plate”, to appear in the International Journal of Pressure Vessel and Piping.

S. Alexandrov and M. Koçak, “Limit load solution for bilayer plates with a through crack subject to tension” Engineering Fracture Mechanics, 1999, 64, (4), 507–511.

A. K. Motarjemi and M. Kocak, “Tensile yield load solutions for centre cracked bi-layer (clad) plates with and without repair welds”, Submitted to the journal of Science and Technology of Welding and Joining.

K.-H. Schwalbe, Y.-J- Kim, S. Hao, A. Cornec and M. Kocak, “EFAM ETM-MM 96: The ETM method for assessing the significance of crack-like defects in joints with mechanical heterogeneity (strength mis-match)”, GKSS/97/E/9. Germany: GKSS research centre, 1996.

S. Al. Graham, “Stress intensity factor and limit load handbook”, Nuclear Electric Report EPD/GEN/REP/0316/98, Issue I (1998).

K.-H. Schwalbe, B. K. Neale and J. Heerens, “The GKSS test procedure for determining the fracture behaviour of materials: EFAM GTP 94”, GKSS 94/E/60, 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Motarjemi, A.K. Fracture Assessment of a Repair-Welded BI-Material Steel by Defect Assessment Procedure SINTAP. Weld World 46, 12–23 (2002). https://doi.org/10.1007/BF03263379

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263379