Abstract

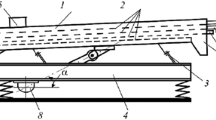

This paper describes the results of pilot plant testwork on a novel single stage zinc solution purification process using a vibratory reactor. This technique was modified for continuous cadmium cementation. There are distinct advantages to combining an intensely agitated reactor with a high mass of precipitant per unit volume in the form of granular zinc instead of zinc dust, including significant reduction of cementation agent consumption and substantial upgrading of the cadmium cement. This technique has the potential to minimize equipment, reduce plant size, and diminish operating costs.

Similar content being viewed by others

References

F.S. Lee and F. Lawrence, “Codeposition of Copper and Cadmium into Zinc,” Trans. Inst. Min. Met., 87, 1978 C170–179.

G.C. Bratt and A.R. Gordon, “Solution Purification for the Electrolytic Production of Zinc,” Australian Institute of Minerals & Metallurgy, Proceedings of Symposium held in Sidney, February 24, 1965, pp. 197–210.

S. Fugleberg, et al., “Solution Purification at the Kokola Zinc Plant,” Lead-Zinc-Tin ′80, pp. 157–71.

A. Pescetelli and S. Cammi, “Zinc Electrolyte Purification by Fluidized Bed Reactors,” International Symposium Refining Processes in Metallurgy, Gesellschaft Deutscher Metallhutten-und Berglente (W. Germany) and Institution of Mining and Metallurgy (G. Britain) held in Hamburg, Oct. 20–22, 1983, pp. 173–85.

M. Esna-Ashari and H. Fischer, “New Process for Zinc Solution Purification,” 111th AIME Annual Meeting, Dallas, TX, Feb. 1982.

M. Esna-Ashari and H. Fischer, “Purification of Zinc Solutions for the Tankhouse,” E & MJ, June 1983, pp. 83–87.

Additional information

Kayo Kangas is currently Zinc Metallurgist at Kidd Creek Mines’ Development and Productivity Group, in Timmins, Canada.

M. Esna-Ashari received his Ph.D. in extractive metallurgy from the Tech University of Clausthal. He is currently Senior Project Manager at the R&D Department of KHD Humboldt Wedag AG, in Cologne, West Germany.

Horst Biallas received his Ph.D. in extractive metallurgy from the Tech University of Clausthal. He is currently Senior Process Metallurgist of the Process Design Department of KHD Humboldt Wedag AG in Cologne, West Germany.

Nestor Torres received his M.S. in metallurgical engineering from Montana Tech. He is currently the Metallurgical Manager of the Humboldt Wedag Division of KHD Canada, in Montreal, Canada.

An erratum to this article is available at http://dx.doi.org/10.1007/BF03258589.

Rights and permissions

About this article

Cite this article

Torres, N., Esna-Ashari, M., Biallas, H. et al. Cadmium Purification with a Vibrating Reactor. JOM 38, 49–52 (1986). https://doi.org/10.1007/BF03257790

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03257790