Abstract

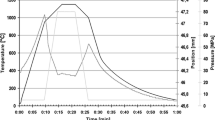

Alumina and partially stabilized ZrO2—with and without Al2O3—have been sintered in a radio frequency induction coupled plasma system. Translation speed of the specimens through the plasma, power level, sintering additives and pressure into the reaction tube were investigated as the experimental variables to elucidate the sintering mechanism(s). Both Al2O3 and partially stabilized Y2O3 + ZrO2 rods have been sintered with final densities greater than 99.7% at a very high densification rate. The grain sizes of the sintered specimens were smaller by a factor of two than the same materials sintered in a non-plasma environment. Specimen temperatures were found to be a function of plasma-supporting gas pressure, applied power and translation speed of the specimens. In the case of partially stabilized ZrO2 in Ar plasma, temperatures increased with the increase in the TS of the specimen up to 6 cm/min.

Similar content being viewed by others

References

D.L. Johnson and R.A. Rizzo, “Plasma Sintering of B,” Alumina Ceramic Bulletin, Vol. 59, No. 4, (1980).

E.L. Kemer and D.L. Johnson, “Microwave Plasma Sintering of Alumina,” Ceramic Bulletin, Vol. 64, No. 8 (1985).

D.L. Johnson, “Plasma Sintering of TiO2,” private communication.

K. Upadhya, “Kinetics and Mechanisms of Plasma Sintering of PSZzO2 and Al2O3,” paper presented in 116 AIME Annual Meeting, Denver (Feb. 1987).

K. Upadhya, “Kinetics of Plasma Sintering of Al2O3,” paper presented in 89th Annual Meeting of Ame. Cer. Soc., Pittsburgh (April 1987).

L.S. Millberg, “The Synthesis of Ceramic Powders,” JOM, Vol. 39, No. 8 (1987), p. 13.

K. Kijima, “Plasma Sintering of Ceramic Materials,” ISPC-7, Eindoven, No. B4-2, July 1985.

F.F. Lange, “Processing Related Fracture Origins: I Observations in Sintered and Isostatically Hot Pressed Al2O3/ZrO2 Composites,” J. Am. Cer. Soc., 66 (6) (1983), p. 396.

J.G. Shackelford, P.S. Nicholson and W.W. Smeltzer, J. Am. Ceram. Soc., 1974 57, p. 235.

S.B. Boskovic and M.M. Ristic, Sov. Powder Metall. Met. Ceram., 1972, 11, pp. 755–759.

S.B. Boskovic and B.M. Zivanovic, J. Mater. Sci., 1974, 9, pp. 117–120.

S.B. Boskovic, M.C. Gasic and M.M. Ristic, in Modern Developments in Powder Metallurgy, Vol. 4, ed. H.H. Hausner, New York, Plenum Press, 1971, pp. 357–365.

J.P. Roberts, J. Hutchings and C. Wheler, Trans. Br. Ceram. Soc., 1956, 55, pp. 75–79.

K. Nii, Z. Metallkd., 1970, 61, pp. 935–941.

D.L. Johnson, “Ultra Rapid Sintering,” in Sintering and Heterogeneous Catalysis, eds. G.C. Kuczyaski, A.E. Miller and G.A. Sargent, Plenum Press, 1984.

Additional information

K. Upadhya received his Ph.D. in metallurgical engineering from the University of Strathclyde in the United Kingdom. He is currently an assistant professor of metallurgical engineering in the Department of Civil Engineering, Mechanics and Metallurgy, at the University of Illinois at Chicago. Dr. Upadhya is also a member of TMS

Rights and permissions

About this article

Cite this article

Upadhya, K. Sintering Kinetics of Ceramics and Composites in the Plasma Environment. JOM 39, 11–13 (1987). https://doi.org/10.1007/BF03257562

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03257562