Abstract

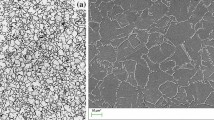

Solute-lean defects, commonly called white spots, are frequently found in superalloys. These defects limit the service life of components made from superalloys, and alloy producers have devoted intense study to their characterization and elimination. Recent work shows that solute lean defects can be classified as “discrete,” “diffuse” and “mini,” and can be further classified into “clean” and “dirty” white spots. More than one formation mechanism for white spots is exemplified by the chemical and morphological differences between discrete, diffuse and mini white spots. White spot detection depends on the thermomechanically developed precipitation of hardening phases, coupled with specific etches that preferentially react to microstructure differences. The white spot defect is indigenous to the vacuum arc remelting process, but defect formation can be minimized by careful process control.

Similar content being viewed by others

References

G.E. Maurer, “Primary and Secondary Melt Processing—Superalloys,” Superalloys, Supercomposites and Superceramics, ed. Tien and Caulfield (New York: Academic Press, 1989),pp. 49–97.

A. Mitchell, “The Production of High-Quality Materials by Special Melting Processes,” Journal of Vacuum Science and Technology, A5(4) (1987), pp. 2672–2677.

F.J. Zanner and L.A. Bertram, “Vacuum Arc Remelting—An Overview” (Report, Sandia National Laboratories, Albuquerque,NM 87185).

R.A. Sprague and S.J. Friesen, “Superalloy Component Durability Enhancements,” JOM, 38(7) (July 1986), pp. 24–30.

T.B. Massalski et al., eds., Binary Alloy Phase Diagrams (Metals Park, OH: ASM, 1986), pp. 1682, 1768.

K.O. Yu, J.A. Domingue, G.E. Maurer and H.D. Flanders, “Macrosegregation in ESR and VAR Processes,” JOM 38(1) (January 1986), pp. 46–50.

A. Mitchell, “White Spot Defects in VAR Superalloy,” Proceedings of the Vacuum Melting Conference on Specialty Metals Melting and Processing (Warrendale, PA: ISS, 1986), pp. 55–61.

J.F. Wadier, G. Raisson and J. Mortet, “A Mechanism for ‘White Spot’ Formation in Remelted Ingots,” Proceedings of the Vacuum Melting Conference on Specialty Metals Melting and Processing, ed. Bhat and Lherbier (Warrendale, PA: ISS, 1985), pp. 119–126.

G.A. Knorovsky et al., “INCONEL 718: A Solidification Diagram,” Met. Trans. A, 20A (1989), pp. 2149–2158.

M.D. Evans and J.F. Radavich, “The Relationship of White Spots and Precipitation Reactions in Alloy 718,” Proceedings of the 1989 Vacuum Metallurgy Conference (New York: American Vacuum Society, 1989), pp. 65–69.

M.C. Flemings, Solidification Processing (New York: McGraw-Hill, 1974), pp. 39–53.

T. Le Roux, D.A. Wells, “An Assessment and Comparison of the Sensitivity of Various Macroetches for Alloy 718,” Superalloy 718—Metallurgy and Applications (Warrendale, PA: TMS, 1989), pp. 109–133.

F.E. Sczerzenie et al., “Evaluation of Continuously Cast VADER Ingots For Superalloy Billet and Bar Applications,” Proceedings of the 1989 Vacuum Metallurgy Conference (New York: American Vacuum Society, 1989), pp. 109–118.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Samuelsson, E., Domingue, J.A. & Maurer, G.E. Characterizing solute-lean defects in superalloys. JOM 42, 27–30 (1990). https://doi.org/10.1007/BF03221049

Issue Date:

DOI: https://doi.org/10.1007/BF03221049