Abstract

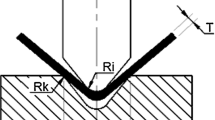

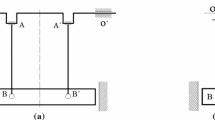

In this study, an artificial intelligent (AI) V-bending process control system with FEM simulation database was developed in order to achieve the production with high accuracy and flexibility. An adaptive filter was proposed to modify the simulated punch force-stroke curve (F-S curve) and to obtain the pseudo experimental one. The filtered simulation results are stored in the database and used to the V-bending process control with an intelligent process control system developed by the authors. The process controlled results show that the FEM simulation database with the compensation filter is very effective for the precision process control system. A high accurate V-bending process was achieved without the trial and error of V-bending tests.

Similar content being viewed by others

References

A. Makiouchi,J. Materials Processing Technology 60, 19 (1996)

M. Yang, N. Kojima, K. Manabe, H. Nishimura,JSME inter. J. Series C 1, 157 (1997).

M. Yang, K. Manabe, H. Nishimura,J. Materials Processing Technology 60, 249 (1996).

M. Yang, N. Kojima, K. Manabe,Japan-U.S.A. symposium on flexible automation, p. 1243 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yang, M., Manabe, K. Application of FEM simulation to AI V-bending process control. Metals and Materials 4, 315–318 (1998). https://doi.org/10.1007/BF03187784

Issue Date:

DOI: https://doi.org/10.1007/BF03187784